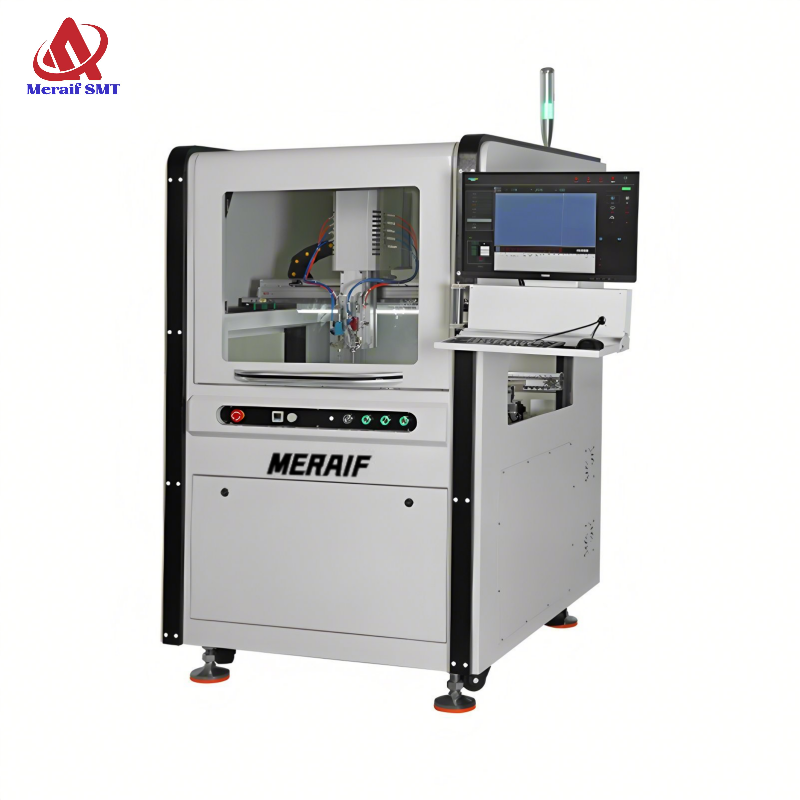

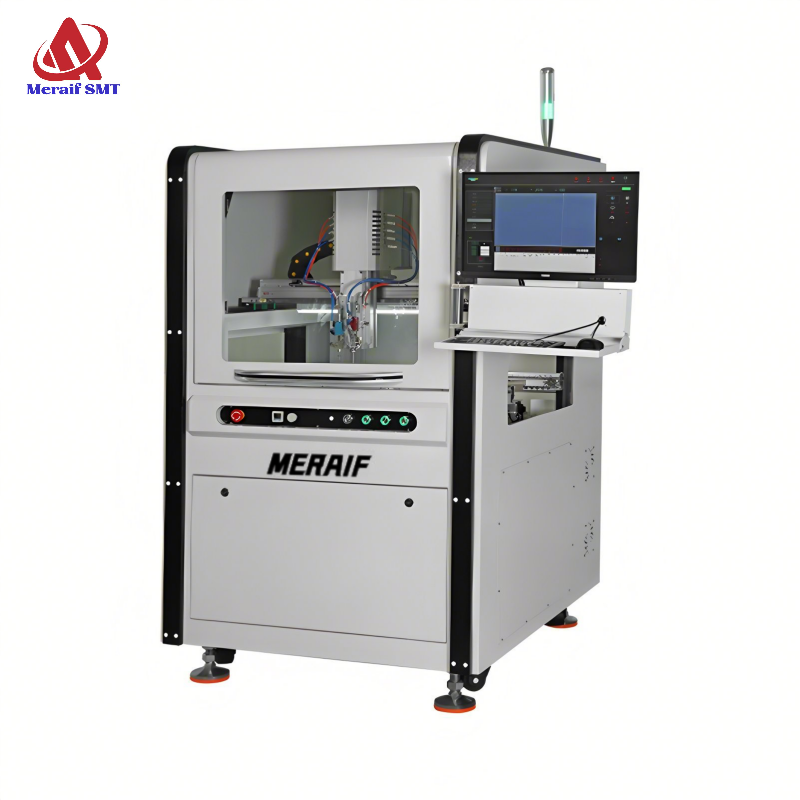

MERAIF MF-1500 UV Oven PCB Conformal Coating Machine Automatic UV Conformal PCB Coating Equipment In SMT Machine Line PCB Coating Machine

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

MERAIF Pcb Coating Machine Technical Parameters :

MERAIF Pcb Coating Machine Details:

Specifications

Parameter

Specifications

Parameter

Model

MF-1500

UV lamp service life

Light decay starts at 800H

Dimensions L*W*H

L1500mm*W1200mm*H1700

Light source type

Mercury lamp (lifetime 800 hours)

Power supply

AC380V

UV zone length

1000mm

Total power

7.5KW

UV lamp power*number

3KW*2

Equipment weight

520KG

UV lamp power density

75W/cm²

Exhaust volume requirement

15m³/min

UV light intensity

80-200mw/cm²

Transport speed

0.5-5m/min continuously adjustable

Irradiation direction

Downward illumination

Conveyor rail width

50-450mm adjustable

UV band and main peak wavelength

280nm-420nm main peak UVA365nm

Modulation mode

Manual adjustment of screw rod

Minimum UV energy value (at speed 5m/min)

150mj/cm²

Transport mode

Deceleration motor drive

Effective irradiation width

450mm

Conveyor rail

Special aluminum alloy + stainless steel chain

UV lamp height adjustment

Adjustable within 10-120mm

Control mode

Standard button type)

UV lamp power adjustment

Strong light/medium light

PCB board component height

Up and down MAX100mm

UV room dynamic temperature

≤100° when idle speed is 2m/min

Conveyor height to ground

900±20mm

UV energy deviation (transport width direction)

Within 20%

Conveyor direction

L-R/R-L

Cooling method

Forced air cooling

Box surface temperature

≤40°

Optional

PLC+touch screen

UV curing oven, also known as UV oven, is a technical equipment that uses ultraviolet (UV) radiation to cure coatings, adhesives or other materials that need to be cured quickly. Its core function is to transform substances from low molecular weight to high molecular weight, thereby achieving rapid curing of materials.

Features:

1. The frame structure of this mechanism adopts 50*50mm square bracket, the bottom is equipped with height adjustment cups and universal casters, the surrounding side panels are made of 1.2mm plate parts, and the surface is electrostatically sprayed with computer white.

2. The conveying mechanism adopts special aluminum alloy guide rails, all stainless steel chains, and PLC touch screen to adjust the track width mechanism. The conveyor belt power system adopts inverter to control the speed.

3. The furnace body adopts movable opening type to facilitate daily maintenance.

4. The UV curing system uses UV lamp tubes as the curing source.

5. The control system hardware adopts standard safety installation method, and the electric control system needs to have electrical safety protection designs such as overload protection, overtemperature protection and fault feedback display.

6. The conveying mechanism is in the upper conveying mode, and the curing furnace body is equipped with an openable mechanism to facilitate the daily maintenance and care of the curing furnace. The conveying of panels is smooth, without abnormal noise, and there is no jamming or collision.

7. The control system adopts PLC controller + touch screen + sensor, with reasonable line layout and neat wiring. The lines are installed in wire troughs, and the overall layout lines must be safe and beautiful.

8. The control system can realize external control to temporarily shut down the curing function, leaving only the conveying mechanism conveying function.

MERAIF Pcb Coating Machine Picture Show:

EXHIBITION:

SMT LINE: