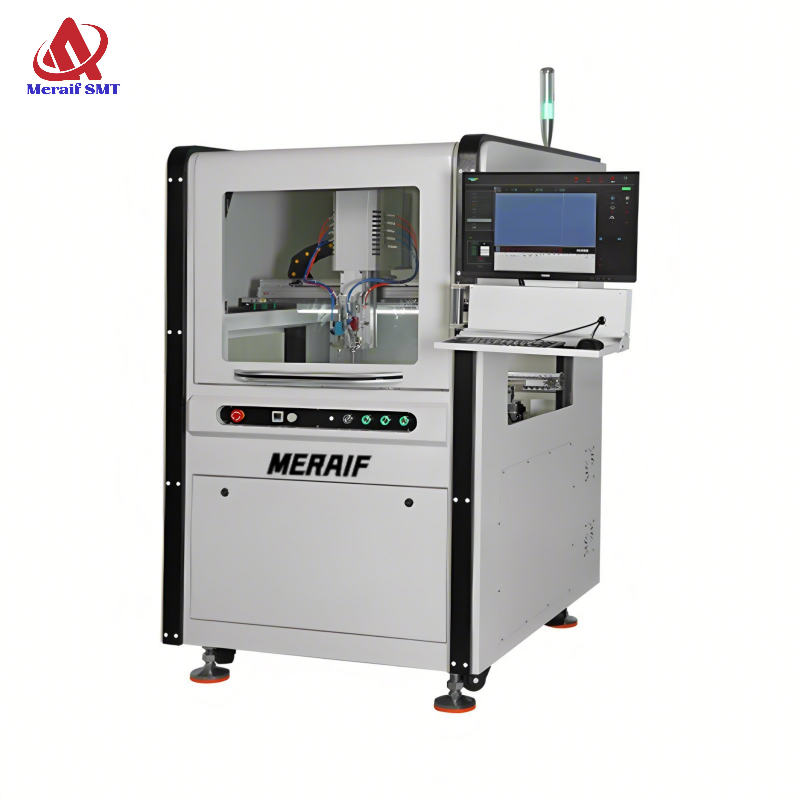

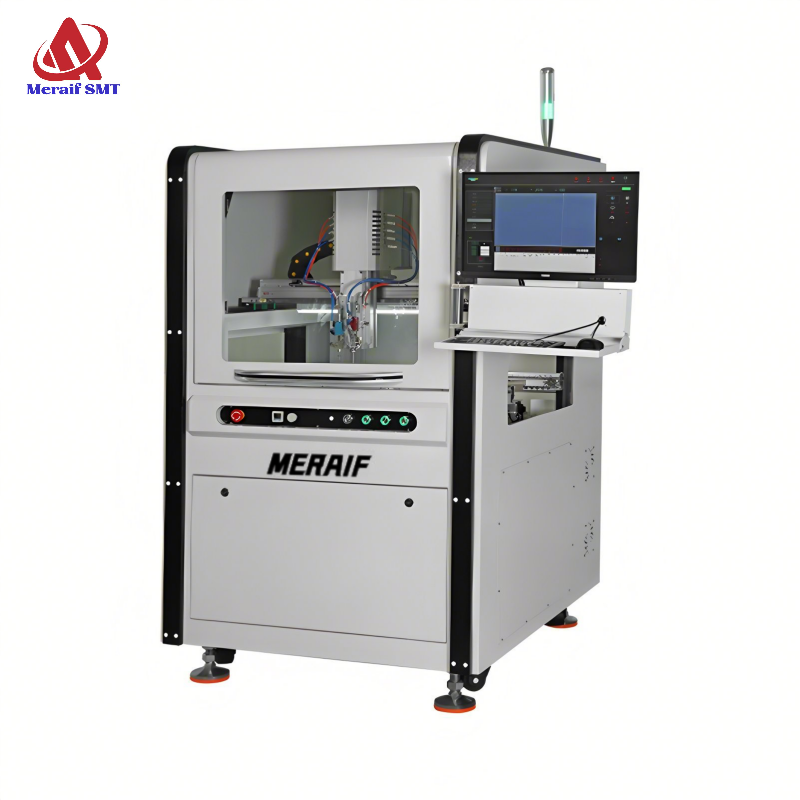

MERAIF MF-H2000 Infrared Curing Oven PCB Conformal Coating Machine Automatic UV Conformal PCB Coating Equipment In SMT Machine Line PCB Coating Machine

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

MERAIF Pcb Coating Machine Technical Parameters :

MERAIF Pcb Coating Machine Details:

Specifications

Parameter

Specifications

Parameter

Parameter type

MF-H2000

Transport speed

0-6m/min

Dimensions L*W*H

2000mm*1050*1300

Transport direction

L-R R-L

Power supply

AC380V

Guide rail amplitude modulation method

Manual adjustment of screw

Power

6KW

Transport method

Deceleration motor (optional stepper motor)

Equipment weight

340KG

Temperature control accuracy

±5℃

Air source

0.4-0.6Mpa

Heating time

<10 minutes

Conveyor guide rail

Hard anodized aluminum alloy + stainless steel chain

Quartz heating tube

12pcs 500W

Temperature range

Room temperature -100℃

Control method

Standard keypad (optional PLC+touch screen)

Infrared curing oven is a kind of equipment that uses infrared radiation technology to cure materials. It is widely used in various industrial fields, especially in application scenarios that require fast and uniform heating.

Infrared curing oven generates infrared radiation through heating elements. These radiations can penetrate the material and act directly on its interior, thereby achieving fast and uniform heating effect. This heating method is particularly suitable for materials that are sensitive to temperature or have a thick thickness.

Features

Infrared curing oven is mainly used for curing and drying various materials. It uses stainless steel heating tubes to circulate hot air on the surface of the material to achieve a fast and efficient curing process. The specific functions are introduced as follows:

1. Efficient heating: The hot air curing oven can quickly transfer heat energy to the surface of the material, improve curing efficiency, and shorten the production cycle.

2. Uniform heating: The hot air furnace can be evenly distributed in the furnace to ensure that all parts of the material are evenly heated, thereby ensuring the consistency of curing quality.

3. Precise control: The equipment is usually equipped with a temperature control system that can accurately adjust and control the temperature in the furnace to meet the curing requirements of different materials.

4. Versatility: In addition to the curing function, the hot air curing oven can also be used for drying, dehydration, preheating and other processes, with high versatility.

5. Energy saving and environmental protection: Compared with traditional heating methods, the hot air curing oven has a higher energy utilization rate, which can reduce energy consumption and environmental pollution.

6. Easy operation: The operation of the equipment is relatively simple, easy to control and monitor, and reduces the skill requirements of the operator.

7. Improve product quality: The materials treated by the hot air curing oven have good curing effect and significantly improved physical properties, which helps to improve the quality and stability of the product.

MERAIF Pcb Coating Machine Picture Show:

EXHIBITION:

SMT LINE: