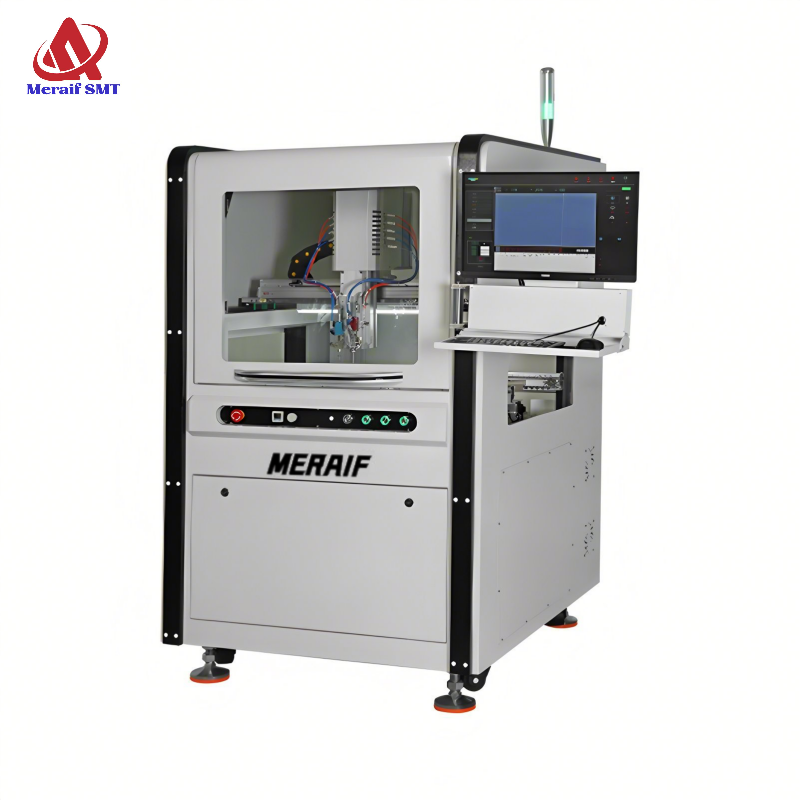

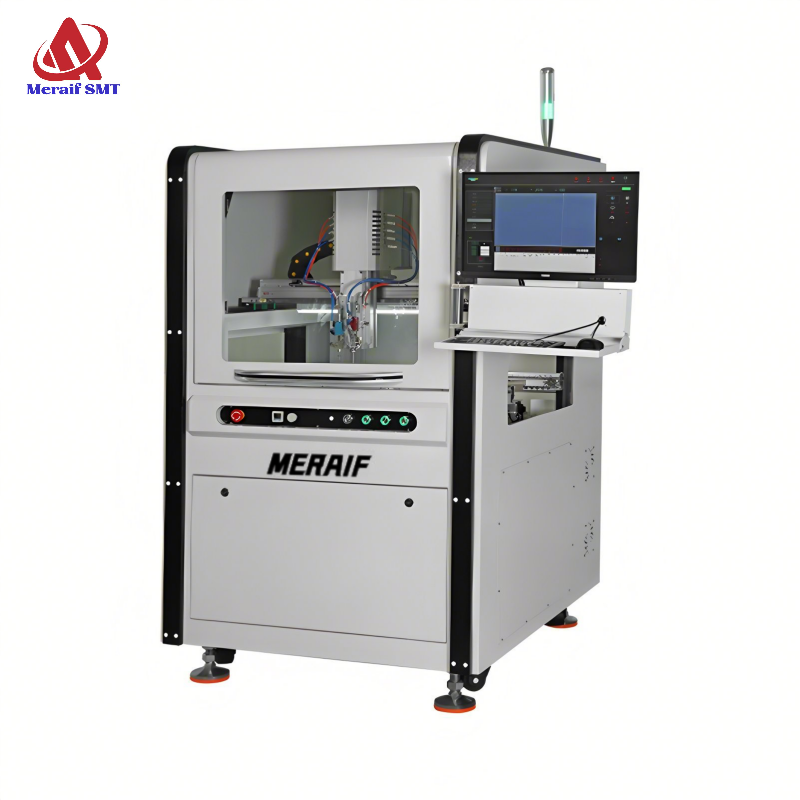

MERAIF MF-H7 PCB Conformal Coating Machine Automatic UV Conformal PCB Coating Equipment In SMT Machine Line PCB Coating Machine

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

MERAIF Pcb Coating Machine Technical Parameters :

|

Specifications |

Model parameters |

Specifications |

Model parameters |

|

Model |

MF-H7 |

Number of program storage |

More than 1000 |

|

Dimensions L*W*H |

L1035mm*W1300mm*H1700mm |

Conveyor rail |

Special aluminum alloy track + stainless steel chain |

|

Weight of equipment |

580KG |

Three-axis drive mode |

Servo motor + ball screw |

|

Transmission motor power |

DC24V 69W*2 |

Conveying direction: |

L → R R → L |

|

Air source |

4-6kgf/cm2 |

Upper layer transmission height: |

920 20mm |

|

Exhaust volume requirement |

6m3/min |

Guide rail amplitude modulation mode |

Software trigger control |

|

Power supply |

AC220V 50/60HZ |

Conveying speed |

2-12m/min |

|

Total power |

1.8KW |

Conveying motor |

Stepper motor |

|

Coating stroke |

X=450 Y=450 Z=100 (mm) |

Lighting part |

Built-in lighting source |

|

Conveyor rail width |

50-450mm |

Detection part |

Built-in detection light source |

|

PCB component height |

Up and down MAX100mm |

Number of glue valves |

1 small atomizing valve + 1 dispensing valve |

|

PCB board edge size |

≥ 5mm |

Spraying method |

Atomizing + dispensing |

|

Spraying width |

3-20mm |

Glue barrel |

10L manual stirring |

|

Control method |

Industrial computer + motion control card |

Cleaning barrel |

2L stainless steel barrel |

|

Software part |

W10 system + coating software) |

Three-axis drive speed |

0-1000mm/s |

|

Programming method |

Manual teaching |

Three-axis drive accuracy |

± 0.02mm |

|

Communication port |

SMEMA interface |

Optional |

Visual intelligent programming |

|

Optional |

Spray valve tilt system |

Optional |

Mark camera |

PCB coating machine is a kind of equipment specially used to apply protective layer on the surface of printed circuit board (PCB), the main purpose of which is to protect PCB from damage by moisture and other environmental factors. The following is a detailed introduction to PCB coating machine:

Types and application scenarios of PCB coating machine

Selective coating machine

Selective coating machine allows precise coating of specific areas of PCB, which is suitable for complex circuit design that requires local protection. Such machines are usually equipped with PLC control system, which can achieve precise operation and efficient coating effect.

Fully automatic coating machine

Fully automatic coating machine can realize automatic loading and unloading and transmission of PCB, which greatly improves production efficiency and reduces labor cost. Such machines are usually equipped with motion control card and genuine Windows 10 system to ensure the stability and reliability of operation.

Special application coating machine

Special application coating machine such as UV curing machine is suitable for special coating needs, such as fast curing and high-precision coating. Such machines are usually equipped with ultraviolet curing device, which can complete the curing process of coating in a short time.

MERAIF Pcb Coating Machine Picture Show:

EXHIBITION:

SMT LINE: