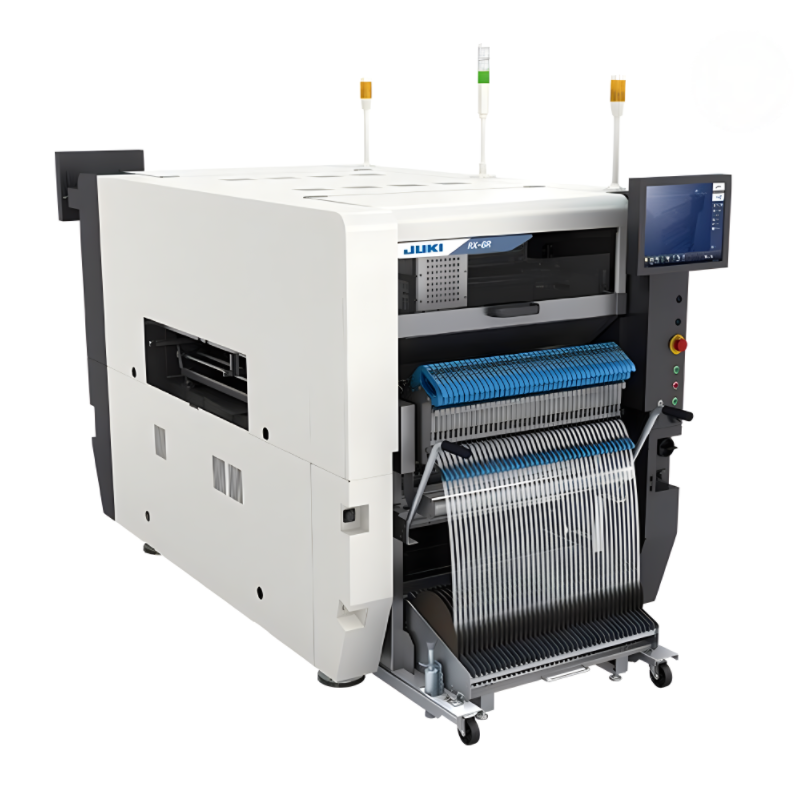

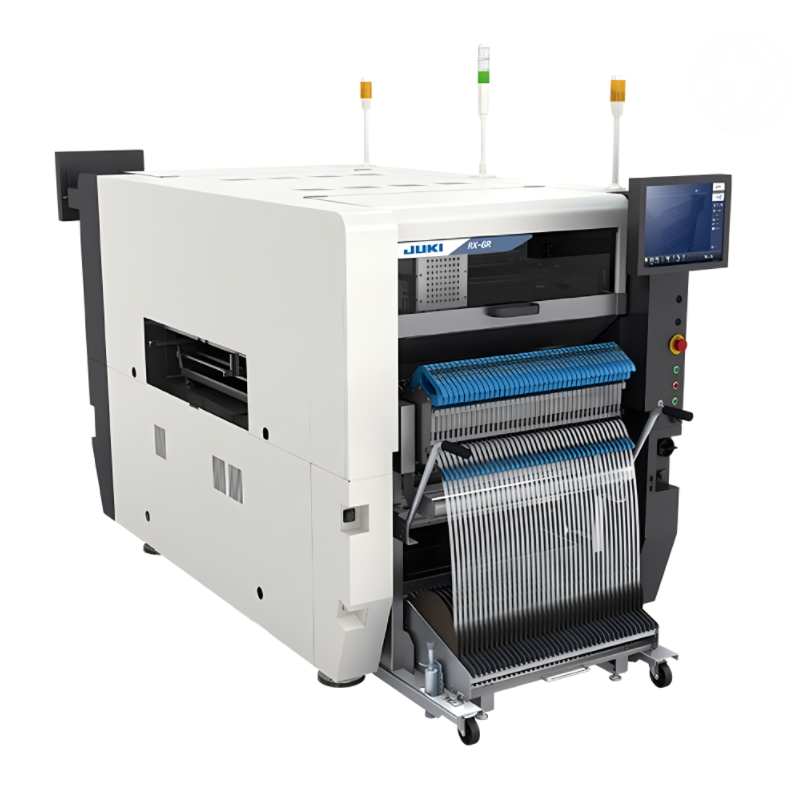

SMT Placement Solution Smd Mounting Machine JUKI RS-1R Fast Smart Modular Mounter Led Pick and Place Machine For SMT Assembly Line SMT Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

JUKI RS-1R Fast Smart Modular Mounter Pick and Place Machine Technical Parameters :

Modle

RS-1R

Conveyor Specification

Standard

150mm conveyor extensions,

upstream and downstream

250mm conveyor extensions,

upstream and downstream

Board Size

Min.

50x50mm

Max.

1buffer

650x370mm (Single clamping)

950x370mm

(double clamping)

1100x370mm

(double clamping)

1200x370mm

(double clamping)

3buffer

360x370mm

500x370mm

600x370mm

Component Height

25mm

Component Size

0201*~74mmx74mm/50mmx150mm

Placement Speed

Optimum

47000CPH

IPC9850

31000CPH

Placement Accuracy

±0.035mm (CPK≥1)

Feeder Inputs

Max. 112(using RF feeder)

Power Supply

AC200~415V(3-Phase)

Apparent Power

Max .2.2kVA

Operation Air Preasure

0.5±0.5Mpa

Air Consumption:

200L/min for internal vacuum generator, 50L/min with optional vacuum pump

Mass(Kg)

Approx. 1,800Kg

Equipment Size (mm)

1,500x1,810x1,400mm

1,800x1,810x1,400mm

2,000x1,810x1,400mm

1.For metric 0201 compliance please contact us.

2.Using RF(RF08AS) feeders

3.A transformer unit(option) is necessary except AC 200V

4.D dimension does not include the front operation monitor, H dimension does not include signal tower.

Options

|

Recognitions system |

10/27/54 mm view camera |

|

Operations system |

Rear-side operation unit/keyboard(front only) |

|

Inspection function |

Conplanarity sensor/Component Verification System(CVS)*5 |

|

Conveyor |

Conveyor extention*6/Support pin/Support sponge |

|

Electrical protection |

CE compatible specification/Ground-fault interrupter |

|

Force Control |

Force control unit/Force control nozzle |

|

Software |

JaNets/IFS-NX/Flexline CAD |

|

Component handling and feeders |

Feeder Trolley RF feeder only/RF-EF dual servo*7/Electric tape feeder(RF/EF*7)/EF feeder adapter*7/Electric stick feeder*7(Type-N/Type-W)/Matrix tray server TR8SR,TR5SNX,TR5DNX/Matrix tray changer TR6SNV, TR6DNV/Dual tray server TR1RB/Nonstop operation function/Tray holder/IC collection belt/Tape reel mounting base(for RF/for EF)Splicing jig/Electric trolley power station PW02*8 |

|

Others |

RS-1R.RS-1 nozzles(with or without RFID tags)/Splicing tape/Big foot/Offset placement after solder screen-printing Solder lighting/Mini-signal light/Non-stop operation/FCS calibration jig/Large ATC/Vacuum pump |

|

1.Please contact for details. 2.One side conveyor extention is also possible. 3.When EF feeders adapt the an attachment of EF feeder, the EF feeder can use on RF/EF feeder trolley and fixed bank(rear side).Please inquire details. 4.Separate connection cables for each model are required. |

|

JUKI RS-1R SMT Pick and Place Machine

The JUKI RS-1R SMT Pick and Place Machine represents a state-of-the-art solution for optimizing pick and place operations in electronic manufacturing. With advanced technology and precision engineering, this machine ensures reliable and consistent performance for various assembly tasks.

Featuring a generous PCB size of 360x370mm, the JUKI RS-1R effortlessly handles larger circuit boards, accommodating diverse production requirements. Its flexible configuration options allow for seamless adaptation to single or double-sided placement needs.

With a capacity of up to 56 feeders in standard mode and an impressive 112 feeders in double-sided mode, this machine offers ample component capacity, facilitating efficient assembly processes. From consumer electronics to industrial applications, the JUKI RS-1R SMT Pick and Place Machine delivers enhanced productivity and precision for your manufacturing needs.

Key Features- High-Speed Precision: Achieve top speeds of up to 47,000 components per hour with our SMT Stencil Printer. Designed for efficient performance with the JUKI RS-1R chip mounter.

- Smart Head Design: The “Takumi head” automatically adjusts height for different components, optimizing efficiency during JUKI RS-1R operations.

- Optimized Line Balance: Our printer self-adjusts based on production needs, reducing workload and adapting to diverse manufacturing requirements.

- Nozzle Traceability: Ensure precise control with RFID-tagged nozzles, improving quality control in your processes.

- Large Nozzle Support: Easily handle large components with a changeable ATC plate supporting nozzles up to 7x28mm.

- Wide Component Range: From small to large components, our printer accommodates various sizes and shapes, including LED diffusion lenses.

- Extended PCB Support: Flexibly handle PCBs up to 650x370mm with single clamping, or expand up to 1200x370mm with optional

EXHIBITION:

SMT LINE: