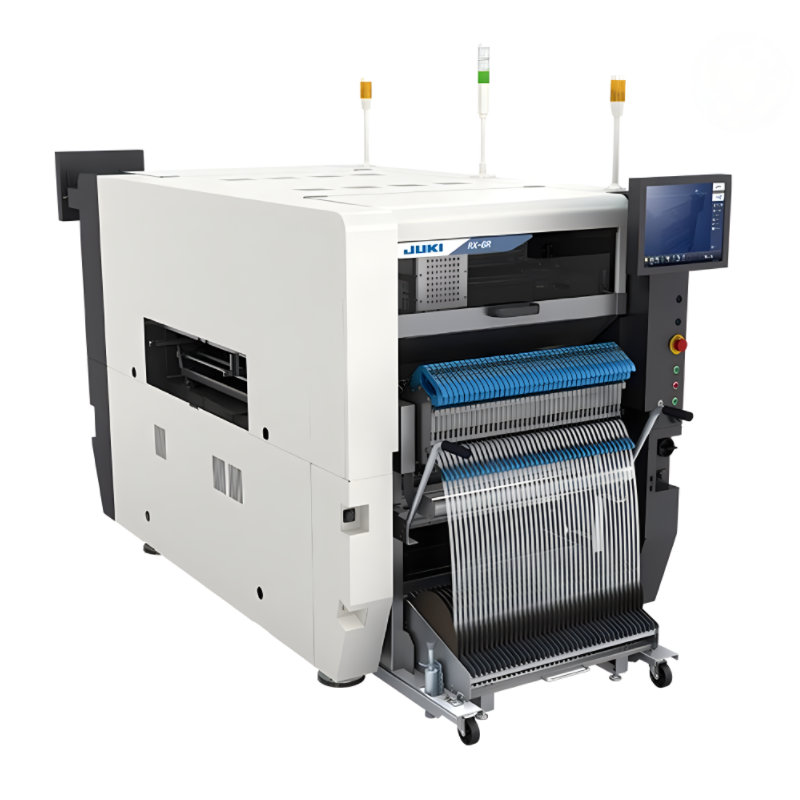

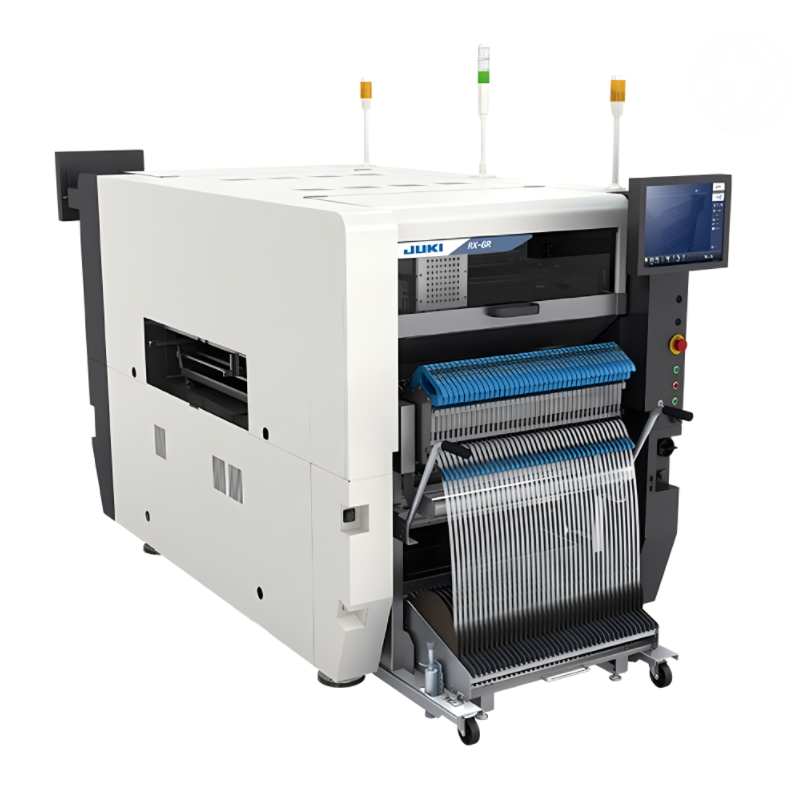

SMT Placement Solution Smd Mounting Machine JUKI KE-3010A High Speed Chip Shooter Led Pick and Place Machine For SMT Assembly Line SMT Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

JUKI KE-3010A High-Speed Chip Shooter Technical Parameters :

Modle Name

KE3010AM/3010AL/3010XL

KE3020VAM/3020VAL/3020VXL

Board Size

M-size

30×250mm

○

○

L-size

10×360mm

○

○

L-Wide size(510×360mm)

0

0

XL-size(610×560mm)

○

○

Longer sized(M-size)

650×250mm

Longer sized(L-size)

800×360mm

Longer sized(L-Wide size)

1,010×360mm

Longer sized(XL-size)

1,210×560mm

Component height

6mm

○

–

12mm

○

○

20mm

–

○

25mm(XL size)

–

○

Component size

Laser Recognition

01005(0402metric)~33.5mm

Vision Recognition

Standard Camera

3mm*3~33.5mm

3mm~74mm OR

50×150mm

High-Resolution Camera

1.0x0.5mm*6~20mm

1.0x0.5mm~48mm OR

24×72mm

Placement speed

CHIP

Optimum

23,500CPH

20,900CPH

IPC9850

18,500CPH

17,100CPH

IC

9,000CPH

17,100CPH

Placement accuracy

Laser Recognition

±0.05mm (Cpk ≥1)

Vision Recognition

±0.04mm

±0.03mm (MNVC±0.04mm)

Feeder inputs

Max.160 in case of 8mm tape(on a Electric double tape feeder)

Power Supply

AC200~415V(3-Phase)

Apparent Power

Max .3.0kVA

Operating air Power

0.5±0.05MPa

Air consumption

50L/min

Equipment Size (mm)

M-size

1,500x1,580x1,500mm

L-size

1,500x1,690x1,500mm

L-Wide size

1,800x690x1,500mm

X-size

2,131x1,890x1,500mm

Mass(Kg)

M-size

Approx. 1,850Kg

L-size

Approx. 1,900Kg

XL-size

Approx. 2,250Kg

JUKI KE-3010A High-Speed Chip Shooter Details:

Expanding High-speed,High Quality Product Line

– Release of High-speed Chip Shooter KE-3010, High-speed Flexible Mounter KE-3020V/3020VR,

and Electric Double Tape Feeder EF08HD –

JUKI Corporation will release High-speed Chip Shooter KE-3010, High-speed Flexible Mounter KE-3020V/3020VR, and Electric Double Tape Feeder EF08HD on January 5, 2012, upgrading our high-speed, high quality Product lines.

JUKI first developed KE Series machines in 1993 as a pioneer of modular placement machines, combining chip shooters and flexible mounters that enable production lines to be flexibly rearranged to match exact production volume. This modular concept has been warmly accepted by many customers since then.

High-speed Chip Shooter KE-3010 is the superior model to KE-2070, and is the first KE Series chip shooter model to support electric feeders.

The High-speed Flexible Mounter KE-3020V/3020VR is a flexible placer that inherits the KE Series functions while dramatically improving its placement speed as the successor to KE-3020/3020R. KE-3020V/3020VR places a wide range of component types. By utilizing “High speed,on-the-fly vision centering”, this machine increases the IC component placement speed by 63% compared to the previous models. In addition, the new high-speed tray server reduces tray changeover time, improving productivity of the line as the speed of component supply has been increased.

Both these placement machines accept electric and mechanical tape feeders. In addition to using electric single lane feeders, it will be possible to use the newly developed electric double tape feeders. The feeder capacity has been up to a maximum 160 types of components, double the number of the previous model. The larger number of tape feeders increases productivity due to the significant reduction in changeover.

By combining KE-3010 with KE-3020V/3020VR, it will be possible to configure a high-speed and high precision production line that would flexibly support small lot and high mix production. Another combination of high-speed modular mounter FX-3R with KE-3020V/3020VR configures a high-speed and high quality production line for large volume production of mobile phones and smart phones, flexibly responding to the diversified demands of customers.

Features

High speed,on-the-fly vision centering

The image recognition performance of camera has been improved. Components picked by the nozzles will be viewed non-stop over the vision recognition camera and our new technology performs image recognition at the same time. Compared with the previous model (KE-3020R), it is a 63% increase in placement speed, 9,470CPH (when using MNVC).

High-speed tray servers (Optional)

TR-7D high speed tray server* greatly reduces tray replacement time. Any tray component supply speed has been dramatically improved.

*TR-7D high speed tray server will also be released in the near future.

Electric double tape feeders

While maintaining the same 17mm width as the previous electronic single lane feeder for 8mm tape, a newly released electric double tape feeder provides the capacity of two 8mm tapes. By mounting electric double tape feeders, it will be possible to set a maximum of 160 component types.

Flexible production line configuration

By combining KE-3020V/3020VR with high-speed modular mounter FX-3R, it will be possible to configure a high-speed and high quality production line with a high versatility. Electric double tape feeders allow the capacity of a maximum of 400 types of components.

By combining KE-3010 with KE-3020V/3020VR, it will be possible to configure a modular type line that supports low volume with high mix production at high speed and high precision while saving space. Using the electric double tape feeders, setting of a maximum of 320 types of components can be possible.

Improves space productivity

Compared with KE-3020/3020R, the exterior dimensions have been made smaller by 175mm in width and 30mm in height, and the weight has been made lighter by 200kg to improve the space productivity.

JUKI KE-3010A High-Speed Chip Shooter Picture Show:

EXHIBITION:

SMT LINE: