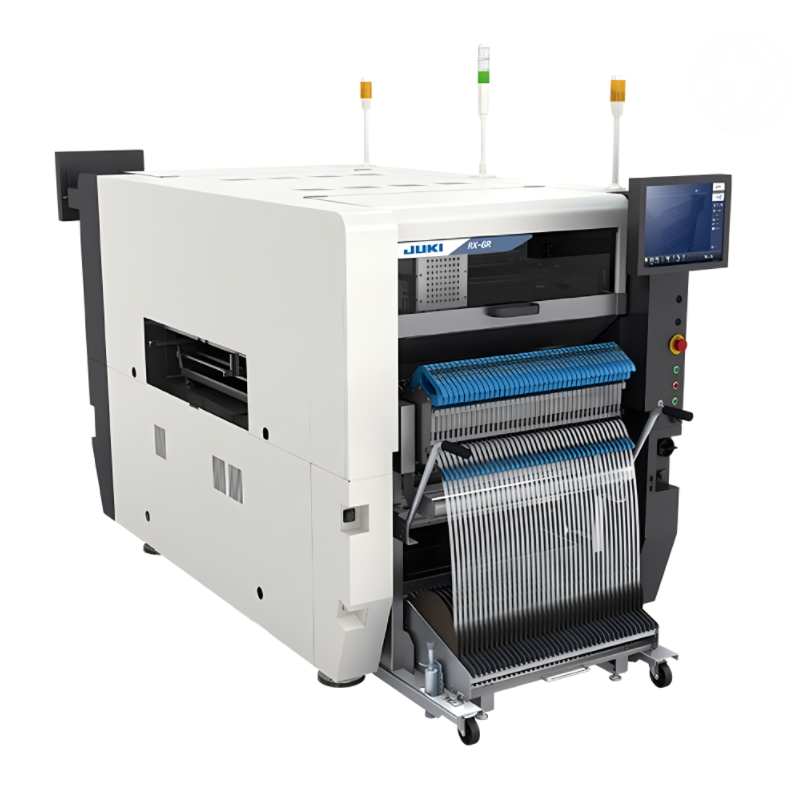

SMT Placement Solution Smd Mounting Machine JUKI RX-8 High-Speed Compact Modular Mounter Led Pick and Place Machine For SMT Assembly Line SMT Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

JUKI RX-8 High-Speed Compact Modular Mounter Technical Parameters :

Modle Name

RX-8

Board Size

50×50~510mm*¹ *²×450mm

Component Height

3mm

Component size

0201*³~5mm

Placement Speed (optimum)

100,000CPH

Placement Accuracy

±0.04mm (Cpk ≥1)

Feeder Supply

Up to 56 *⁴

Power Supply

3Phase AC200V、220V~430V *⁵

Apparent Power

2.1kVA

Operating air Power

0.5±0.05MPa

Air consumption(standard)

20L/min ANR (during normal operation)

Machine Dimensions(W×D×H)*⁶

998mm×1,895mm×1,530mm

Machine Weight

1,810kg(with fixed bank)/1,760kg(with bank changing)

*1 BOC, Bad Mark, and 2D barcode can be read only if board is from 50mm to 350mm

*2 In long board mode (two boards can be produced simultaneously up to 420mm long ).

*3 Please contact FLASON SMT for details

*4 When use RF08AS Feeder

*5 220V-430V requires a separate transformer.

*6 Depth D does not include the monitor, and height H does not include the signal light when conveyor height is 900mm.

|

Options |

|

|

Conveyor System |

Support Pin/Support plate |

|

Other |

Dedicated Nozzle/Spare Nozzle cartridge/Connecting Cable/Earth leakage circuit breaker / Work lighting |

|

Available Feeders |

Feeder bank exchange trolley /Electric tape feeder / Fixed(RF)bank / Feeder setup station tape splicing jig/Feeder adjustment jig / External power supply for the electric feeder banks |

|

Software |

|

|

JaNets* |

User definition/Facility definition/Component DB/Creating Production programs/Line optimization/ Line monitoring/CAD conversion/ Cluster optimization |

|

IFS-NX |

Prevents loading parts in the wrong location/Tracks remaining quantity of parts/External setup verification/Random Feeder setup |

|

Virus measurement software |

White list(Standard) |

JUKI High-Speed Compact Modular Mounter RX-8

The RX-8 efficiently handles microchip SMD components from miniature 0.4 mm x 0.2 mm up to 5 mm square, and as tall as 3 mm in height. The mounter achieves super high speeds for small parts, both discrete chips and ICs, at high speed using two revolving mounting heads.

The number of nozzles *1 on each mounting head has been increased from 16 to 20 (to 1 head) to improving the number of parts that can be acquired at one stop from one feeder. As a result, it achieves 100,000 CPH *3 in the same footprint as the previous model, the RX-7, but it is 1.3 times *2 faster, and can now claim the highest “area productivity” found in the 2 revolving head mounter class.

In addition, the new P20 revolving “Planet Head” is ideal for rapid mounting of the same part number, with high-quality tuned for volume production of LED lighting, and specifically panel board production using LED edge lights.

In recent years, with the full-scale implementation of 5G (5th generation mobile communication system) and the progress of the latest technologies such as AI and sensing, the electronics assembly industry is required to support IoT implemented in various products such as smartphones, wearable devices, next-generation EV automobiles, and collaborative service robots. Digitalization is driving further miniaturization and density of SMD mounting sites on electronic boards, and this it is required not only to introduce machines with high processing speeds and capability, but also to build SMT mounting lines that have the flexibly to handle various production mixes and to make the entire factory smarter by linking both horizontally with the system from machine to machine in a line, but also vertically to the factories ERP/MES ecosystem of connected software.

By combining the RX-8 together with the RS-1R, our flexible modular mounter, it is possible to build a super high-speed, high-quality SMT line that supports the widest range of products. In addition, by linking with Juki’s Advanced Network System (JaNets) software, the mounting systems software further contributes to improving the productivity of the entire factory, including visualization of the operating machine status.

Feature

(1) High-speed installation of 100,000 CPH and best-in-class area productivity

The compact size with a width of 998 mm has achieved a maximum tact of 100,000 CPH (optimal conditions). It saves space and achieves high productivity.

(2) Newly mounted head (P20 planet head) realizes even higher precision mounting

The new P20 Planet Head is ideal not only for chips and small ICs, but also for lighting using LED edge lights that require high accuracy, panel board production, and wearable device production.

(3) Flexible line construction and high-quality production

In combination with the high-speed smart modular mounter RS-1R, flexible line construction is possible and it supports a wide range of production items.

In addition, we will realize high-speed, high-quality production by connecting with our full lineup of products including pre- and post-process equipment, printing machines, and inspection machines.

(4) Supporting production control and productivity improvement of the entire factory

By using the mounting integrated system software “JaNets”, it is possible to link with the core system as well as production control on the mounting line. It visualizes the production progress, equipment operation status, errors, etc. at the mounting site, speeds up the response, and supports the optimum operation of the production line.

JUKI RX-8 High-Speed Compact Modular Mounter Picture Show:

EXHIBITION:

SMT LINE: