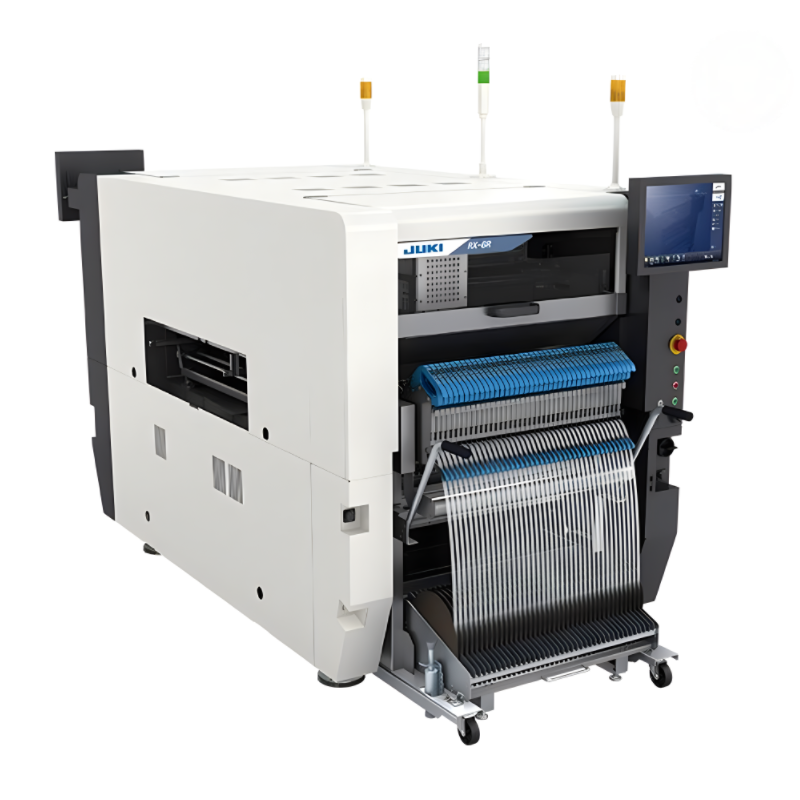

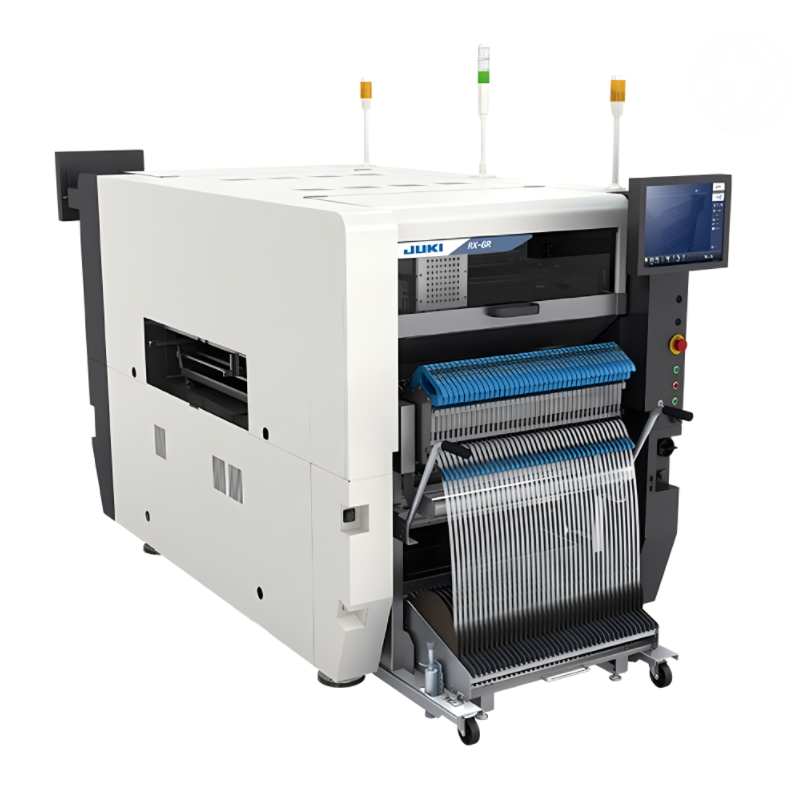

SMT Placement Solution Smd Mounting Machine JUKI RX-6R High-Speed Compact Modular Mounter Led Pick and Place Machine For SMT Assembly Line SMT Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

JUKI RX-6R High-Speed Compact Modular Mounter Technical Parameters :

Modle Name

RX-6R

RX-6B

Head

6x6 nozzle head

6x6 nozzle head

6x3 nozzle head

Board Size

Single Lane:

50x50~610x590/905x590mm(2times clamping)

Dual Lane:

–

50x50~360x250mm

Component Height

6/12/20mm

6/12/20/25/33mm

Component Size

Laser recognition(01005)

0402~50mm

0402~50mm

0402~33.5mm

Vision recognition

Standard camera

3~33.5mm

3~33.5mm

3~100mm/50×180mm

High-resolution camera

1005~24mm

1005~20mm

1005~48mm/24×72mm

Placement Speed

CHIP

Optimum

52,000CPH

42,000CPH

34,000CPH

IPC9850

29,000CPH

26,000CPH

23,000CPH

IC

14,000CPH

14,000CPH

11,000CPH

Placement Accuracy

Laser recognition

±0.04mm(Cpk≧1)

±0.04mm(Cpk≧1)

±0.04mm(Cpk≧1)

Vision recognition

±0.04mm

±0.04mm

±0.03mm

Component Loading Quantity

Max.160 in case of 8mm tape(on a Electric double tape feeder)

Power Supply

AC200~415V,(3-Phase)

Apparent Power

Max .3.5kVA

Operation Air Preasure

0.5±0.5Mpa

Air Consumption:

100L/min

Mass(Kg)

Single Lane

Approx. 1,800Kg

Approx. 1,800Kg

Dual Lane

–

Approx. 1,830Kg

Machine dimensions (W×D×H)

1,250x2,095x1,440mm

1.Single lane conveyor specification mode max. 360x450mm.

2.Optional.

3.Placement speed of IC components is estimated value when placing 36 pieces QFP Component(dimension 10mm sauare of smaller) on M size PWB overall,picking from both front and rear side with all nozzles simutanesuly.

4.Machine width measure (D) does not include display.Machine heiht measure (H)does notin clude signal light an display.

Options

|

Recognitions system |

High-resolution camera |

|

Operation System |

Windows 7 |

|

Inspection function |

Conplanarity sensor/Component Verification System(CVS)/SOT detection check funtion |

|

Conveyor |

Conveyor extention |

|

Electrical protection |

Ground-fault interrupter |

|

Force control |

Force control nozzle |

|

Others |

FCS Calibration Jig/Mini-signal light tower/Super foot/Offset placement after solder screen-printing/Solder lighting/Placement monitor(data srorage &analysis function)/Flucer unit (Linear Tyoe,Rotary Type) Csster/Rear-side operation unit |

|

Software |

IS/IFS-NX/EPU |

|

Component handing and feesers |

Feeder Trolley/Electric tape feeder/Electric stick feeder/High Speed Matrix Tray Server TR7DN/TR8S Tray Holder/IC collection belt/Trash box/Tape reel mounting base/Feeder trolley/Feeder stocker/Splicing jig/Feeder Calibration Jig with Monitor/Tray holder/Eletric Trolley Power Station |

JUKI RX-6R High-Speed Compact Modular Mounter Details:

JUKI’s RX-6R/RX-6B

High Speed Compact Modular Mounter

Brand new Modular Mounter RX-6 debut

-Combine High Productivitiy, High Flexiblity, High Quality

Features

▶This is applicable to dual-lane production.*6

▶Compact footprint : the width is just 1.25m

▶Equipped with standard Placement Monitor check function.*1

▶Replaceable head allow you to configure a production line best suited to the current repirments.*6

▶High-speed component placement using high-speed non-stop vision recognition.*3

▶Wide range of components and boards: tall components, large components and large boards.

▶Brand new Matrix Tray Sever TR8S improves the component capability and productivity.

JUKI RX-6R High-Speed Compact Modular Mounter Picture Show:

EXHIBITION:

SMT LINE: