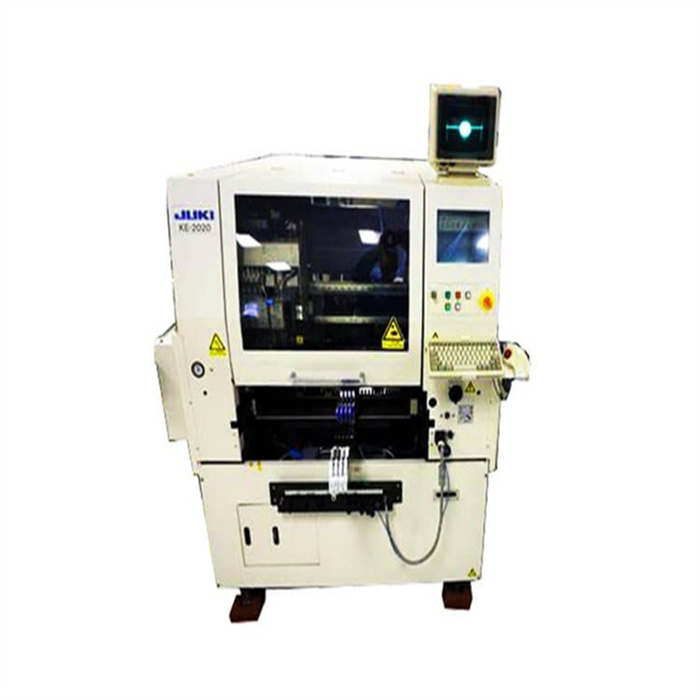

SMT Placement Solution Smd Mounting Machine JUKI KE-2070 Hight-Speed Chip Mounter Led Pick and Place Machine For SMT Assembly Line SMT Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

JUKI KE-2070 High-Speed Chip Shooter Technical Parameters :

Modle

KE-2070

Board size

M-size

330×250mm

L-size

410×360mm

E-size

510×460mm*1

Component height

6mm,12mm

Component size

Laser recognition

0402 (01005) 33.5mm

Vision recognition

3mm*2 33.5mm

1.0×0.5mm*3 20mm (Option)

Placement speed

Chip(IPC9850)

16,000CPH

IC*4

4,600CPH*5

Placement accuracy

Laser recognition

±0.05mm

Vision recognition

±0.04mm

Feeder inputs

Max. 80 on 8mm T/F*6

Power Supply

3-phaseAC200-415 V

Apparent Power

Max .3.0kVA

Operation Air Preasure

0.5±0.5Mpa

Air Consumption

Max .345L/min

Mass(Kg)

Approx. 1,530Kg

Equipment Size (W×D×H)

M-size

1,400x1,393x1,440mm

L-size

1,500x1,500x1,440mm

E-size

1,730x1,600x1,440mm

JUKI KE-2070 High-Speed Chip Shooter Details:

Release of Industry’s First “Placement Monitor” Capable of Capturing the Instant of Component

Pickup and Placement as the “Eyes of the Mounting Process”

JUKI Corporation is to release the Placement Monitor, an industry-leading epoch-making system, as an option for the High-speed Chip Shooter KE-2070 that captures the instant of component pickup and placement using ultra-small cameras attached inside the chip shooter.

In recent years, a large broadening has been seen in electronic equipment manufacturing processes using surface mount technology, which has spread from mobile devices such as mobile phones to electric control units (ECU) for automobiles that increasingly incorporate electronics. In each of these manufacturing work places, tackling progress in high-density mounting and productivity improvement is key, as well as being able to realize an extremely high-order of manufacturing from the point of view of product quality and reliability, including the reduction of manufacturing defects, improvement of first-pass yield, and the securing of traceability.

In the circuit board manufacturing processes for each of these products, although quality control is widely carried out using printed circuit board appearance inspection equipment after solder printing, after component placement, and after soldering, so that a “result” is obtained following the occurrence of a defect, this does not allow direct understanding of the cause of the defect. Additionally, in the process to realize the product quality before mass manufacturing, work that places a great burden on the operator, such as repeatedly analyzing several tens of thousands of test results, or imaging and checking the component pickup and placement actions from outside the machine using high-speed cameras, will have to be carried out in order to eliminate the causes of defects.

With the release of the Placement Monitor, detailed monitoring of the mounting process is possible using the ultra-small cameras built into the High-speed Chip Shooter KE-2070 head unit to capture images during the component pickup and placement for each nozzle.

The development of this function, which allows capturing of the instant of pickup and placement inside the shooter has been realized for the first time by JUKI, and can be said to be an industry-leading epoch-making system for customers who are tackling high-order product quality control.

The defect analyzing tool for mass production, the work efficiency improvement tool when starting up new model types, and the traceability for product quality assurance as recording equipment can also be utilized.

As the “eyes of the mounting process”, the Placement Monitor is an innovative product that opens up the future for customers who are seeking to maintain safety and high reliability, as well as customers who are aiming to improve product quality.

JUKI KE-2070 High-Speed Chip Shooter Picture Show:

EXHIBITION:

SMT LINE: