SMT Placement Solution Smd Mounting Machine JUKI KE-2060 Hight-Speed Flexible Mounter Led Pick and Place Machine For SMT Assembly Line SMT Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

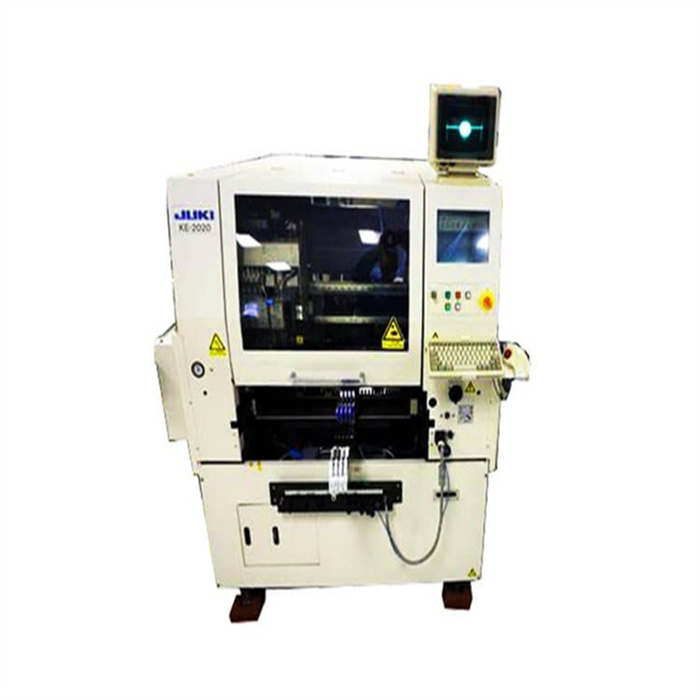

JUKI KE-2060 Hight-Speed Flexible Mounter Technical Parameters :

JUKI KE-2060 Hight-Speed Flexible Mounter Details:

The Juki 2060 pick and place machine is an advanced equipment used in the electronics manufacturing industry for high-speed and accurate placement of surface mount components onto printed circuit boards (PCBs). It offers a wide range of functionality and features that enhance placement accuracy, speed, and flexibility.

Functionality:

1. Component Placement: The Juki 2060 pick and place machine specializes in the precise placement of surface mount components onto PCBs. It utilizes advanced vision systems and robotic arms to accurately pick components from feeders and place them onto designated locations on the PCB.

2. High-Speed Placement: The machine is capable of high-speed operation, ensuring fast and efficient placement of components. It features multiple placement heads and a robust conveyor system, enabling quick turnaround times and improved production efficiency.

3. Component Compatibility: The Juki 2060 pick and place machine supports a wide range of surface mount components, including resistors, capacitors, integrated circuits (ICs), ball grid arrays (BGAs), quad flat no-leads (QFNs), and microcontrollers. It accommodates various component sizes and types, making it suitable for diverse PCB assembly requirements.

4. Vision Systems and Alignment: The machine is equipped with advanced vision systems that provide precise component alignment and inspection. These systems use cameras and image processing algorithms to accurately identify component positions and orientations, ensuring proper alignment during the placement process.

5. Feeder Flexibility: The Juki 2060 machine supports various types of feeders, including tape feeders, stick feeders, and tray feeders. It allows for easy and efficient handling of different component types and packaging formats, ensuring smooth and uninterrupted production.

6. Intelligent Feeder Management: The machine features intelligent feeder management capabilities. It can automatically detect and track the component inventory in each feeder, optimizing component usage and reducing setup time between production runs. This feature enhances productivity and minimizes operational errors.

Usage Range:

The Juki 2060 pick and place machine is suitable for a wide range of PCB assembly applications, including:

1. Surface Mount Technology (SMT) Assembly: It is used in the production of PCBs with surface mount components. The machine accurately places components onto the PCB pads, ensuring precise alignment and reliable solder connections during the subsequent soldering process.

2. Prototype Development: The machine is ideal for prototype development and small-scale production. Its flexibility and quick setup time allow for rapid iteration and validation of PCB designs, facilitating efficient product development cycles.

3. Medium to High Volume Production: The Juki 2060 machine is suitable for medium to high volume production environments. Its high-speed placement capabilities and efficient feeder management enable fast and reliable assembly of large quantities of PCBs.

4. Multi-Project Production: The machine is capable of handling multi-project production, where different PCB designs are produced in the same production run. It offers quick changeover between projects, minimizing downtime and facilitating efficient production of diverse PCB assemblies.

5. Automotive, Consumer Electronics, and Telecommunications: The Juki 2060 pick and place machine finds applications in various industries, including automotive, consumer electronics, and telecommunications. It meets the high-quality and reliability requirements of these sectors, ensuring accurate and consistent placement of components.

The Juki 2060 pick and place machine provides advanced functionality for high-speed and precise component placement in PCB assembly. It plays a critical role in the electronics manufacturing process, ensuring efficient production and reliable performance of electronic products.

JUKI KE-2060 Hight-Speed Flexible Mounter Picture Show:

EXHIBITION:

SMT LINE: