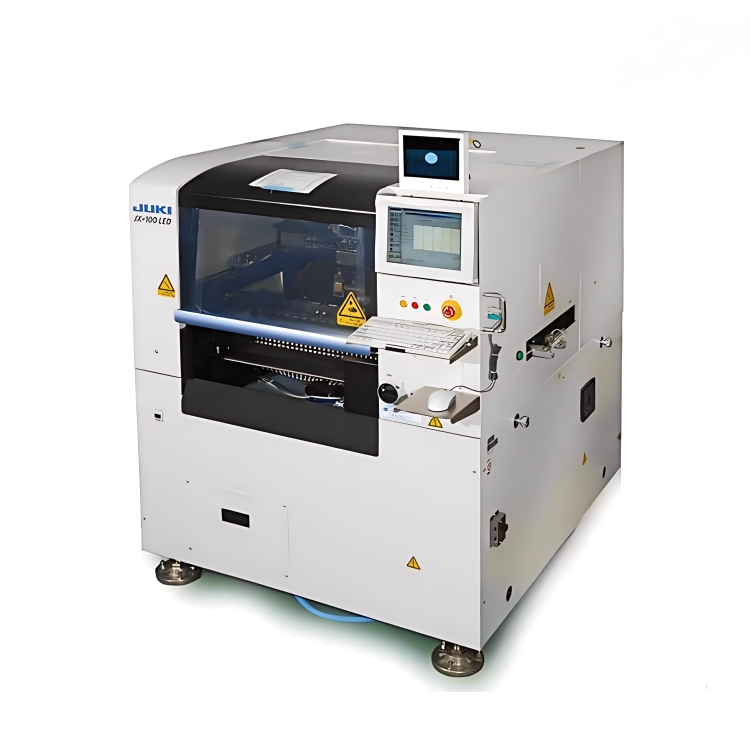

SMT Placement Solution Smd Mounting Machine JUKI JX-300LED LED Mounter Led Pick and Place Machine For SMT Assembly Line SMT Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

JUKI JX-300LED LED Mounter Technical Parameters :

Modle

JX-300LED

Board size

Standard

50×50~1,200×360mm

Longer sized PWB

50×50~1,500×360mm

Component height

6mm/12mm

Component size

Laser

Min.(0201)0603mm~Max.33.5mm

Placement speed

IPC9850

13,900CPH

Placement accuracy

±0.05mm(Cpk ≥1)

Feeder inputs

Max.40 in case of 8mm tape

Power Supply

AC200~415V(3-Phase)

Apparent Power

Max .3.0kVA

Operation Air Preasure

0.5±0.5Mpa

Air Consumption

(standard starus)

standard

Max .345L/min

Vacuum pump

Max .50L/min

Mass(Kg)

Approx. 1,420Kg

Equipment Size (mm)

1,920x1,393x1,440mm

JUKI JX-300LED LED Mounter Details:

Special function and performance for LED board production

Released LED Mounter JX-300LED

JUKI released LED Mounter JX-300LED, a specialized model with efficient function and performance for LED board production. Today the demand of LED, which is used for lighting equipments or LCD display for television and computers, is sharply expanding due to its energy saving and long-life feature. JUKI already have Flexible Compact Mounter JX-100LED for LED productions, but this new JX-300LED has expanded its PWB size capacity and improved the placement speed.

JX-300LED is now capable for max 1200 mm PWB, high demand size for LED lighting equipments and middle/large size LCD backlight, as standard feature. It will be able to produce PWB of max 1500mm, largest class in the business, by option. Additionally, high accurate placement of light diffuser lens, a producing technology recently expanding for LCD backlight production, is possible by using our original laser sensor to recognize the boss*and identify the correct direction of the lens. The placement speed improved, as result of function improvements including the conveyance method.

JUKI will extend the sales for LED machines, JX-300LED and JX-100LED, to meet the growing demand of LED by expanding the capable board size and improving the placement speed.

Features

Improved placement speed

The conveyor transportation time is cut by changing the PWB stopper method from sensor control to mechanical stopper, and by modifying the PWB holding method to face-side clamp.

Mid-size chip LED components can be placed in 18,200 CPH. (with 12mm Tape Feeder, 6 nozzle alternate placement by 3 nozzle simultaneous pick x 2 times)

LED Placement

Essential capabilities provide high productivity at low cost.

Capable of PWB size 610mm x 360mm by one time clamp, 1200mm x 360mm by two times clamp, and 1500mm x 360mm by three times clamp.

When producing long board with several clamps, the machine is able to recognize the solders printed on the electrodes as BOC mark. (option)

Efficient component supply of tray components (Ex. light diffuser lens) will be possible by using Tray Holder or Matrix Tray Server. (option)

Realized space saving machine size, 1920mm x 1393mm, which is smallest class for mounter capable of 1200mm x 360mm PWB production.

Safe Operability

Equipped with GUI (Graphical User Interface), which enables easy operation even for beginners. Operation by touch panel, without keyboard, is also possible. (option)

Vertical startup is possible, since the time for preparing data is greatly shortened due to laser recognition method of components.

High Cost-Effectiveness

Power saving feature; apparent power 3.0 kVA,

Nozzles, Tape Feeders, and production data are compatible with the other models, so the existing properties can be utilized.

JUKI JX-300LED LED Mounter Picture Show:

EXHIBITION:

SMT LINE: