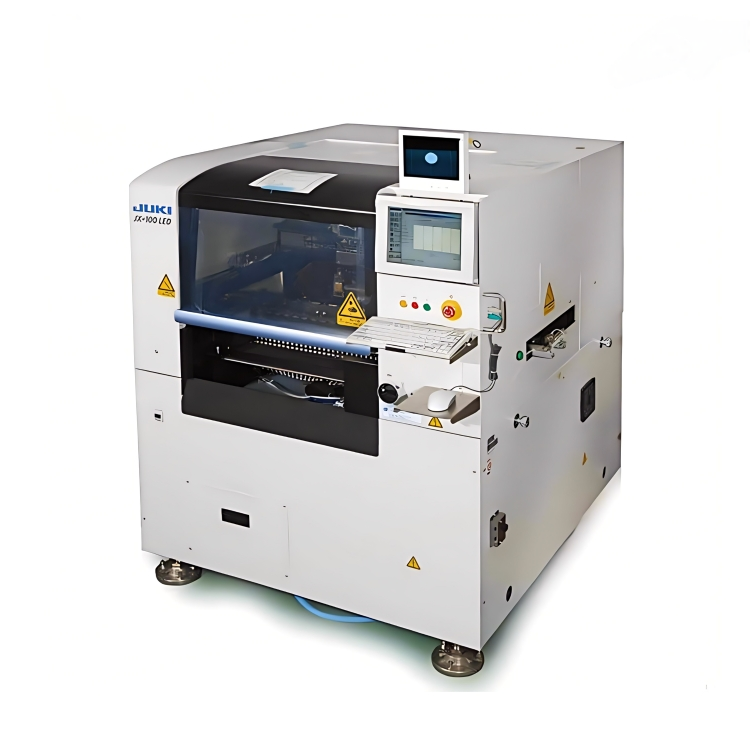

SMT Placement Solution Smd Mounting Machine JUKI JX-100 Flexible Compact Mounter Led Pick and Place Machine For SMT Assembly Line SMT Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

JUKI JX-100 Flexible Compact Mounter Technical Parameters :

|

Modle |

JX-100LED |

|

|

Board size |

Min.50×50~Max.800×360mm |

|

|

Board positioning |

Shape reference |

|

|

Component height |

12.0mm*2 |

|

|

Component size |

Min.(0201)0603mm~Max.33.5mm |

|

|

Component centering device |

Laser centering(LNC60) |

|

|

Placement speed (chip) |

IPC9850 |

15,300CPH |

|

Placement accuracy |

±0.05mm (±3σ) |

|

|

Feeder inputs |

Max.30 8mm tape feeders,60 with optional rear bank |

|

|

Power Supply |

AC200~415V(3-Phase) |

|

|

Apparent Power |

Max .2.2kVA |

|

|

Operation Air Preasure |

0.5±0.5Mpa |

|

|

Air Consumption (standard starus) |

Standard |

Max .345L/min |

|

|

Vacuum pump |

Max .50L/min |

|

Mass(Kg) |

Approx. 1,000Kg |

|

|

Equipment Size (mm) |

1,390x1,270x1,440mm |

|

JUKI JX-100 Flexible Compact Mounter Details:

Flexible compact mounter JX-100

JUKI’s newly released JX-100 is a high-performance, low-priced mounter that has been developed for these types of customers. Regarding the development, investigations into actual customer conditions were implemented, and by narrowing down the functions to the minimum essential items it was possible to realize both a compact size and low cost while also achieving a high level of productivity with an optimum tact of 0.187 second/chip (19,300 CPH). In addition, consideration has been given to allow operators with little experience in mounter operation to use the equipment with confidence by incorporating easy usability, so that smooth production startup will be possible. Circuit board transfer allows switching between straight/U-turn to support free layout design, based on simple manufacturing methods such as cell production. In addition, because the nozzles and feeders are compatible with those in JUKI’s more advanced machines, transfer of assets is possible without waste in the situation where future expanded manufacturing is planned.

The JX-100, which dramatically improves productivity and reliability with the minimum of investment, is the optimum single unit as an initial investment mounter for realizing automation of manual placement and manual insertion mounting.

In addition to the speed and cost benefits, because the mounter incorporates highly evaluated high-quality functions from more advanced machines, it can be used in a wide range of applications as trial manufacturing equipment and as supplementary equipment for existing mounting lines.

By making best use of JUKI’s infrastructure and know-how in the industrial sewing machine business, in which the company maintains the world’s top share, JUKI has supplied more than 20,000 mounter units worldwide over a more than 20 year period. In the future, JUKI will continue to supply products and services that support a wide range of needs relating to mounters to realize customer satisfaction in an aim to also become the world’s top brand in the field of mounting machines.

JUKI JX-100 Flexible Compact Mounter Picture Show:

EXHIBITION:

SMT LINE: