KOH YOUNG KY8030-2 3D SPI Online SMT Machine SMT 3D SPI KOH YOUNG 3D SPI Inline 3D Solder Paste Inspection System SPI MachineIn SMT Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

KOH YOUNG KY8030-2 SMT LINE SPI Technical Parameters :

|

Model |

KY8030-2 |

||

|

Resolution |

15um |

20um |

25um |

|

Inspection time(per FOV) |

0.47sec |

0.47sec |

0.47sec |

|

Max. PCB size: |

|||

|

Machine Size |

M |

L |

XL |

|

Max |

330 x 250 mm |

510 x 510 mm |

810 x 610 mm |

|

FOV Size |

30 x 30mm |

||

|

3D Inspection Speed |

22.5-56.1cm2/Sec |

||

|

Distance between deposit |

100 Micrometer |

||

|

Inspection Size |

10 x 10mm |

||

|

Inspection Height |

400 Micrometer |

||

|

PCB Size Handling |

330 X330mm To 850 x 690mm |

||

|

Air And Power Supplies |

Single Phase 200-240vac,50-60hz,5kgf/ Cm2 |

||

KOH YOUNG KY8030-2 3D Solder Paste Inspection Machine

The KY8030-2 has maintained the industry's leading position as the best-selling True 3D Solder Paste Inspection System since entering the market. Combining Koh Young's patented 3D dual-inspection Moiré projection technology, it effectively eliminates critical shadow and specular reflection challenges other 3D inspection systems simply cannot address.

Feature:

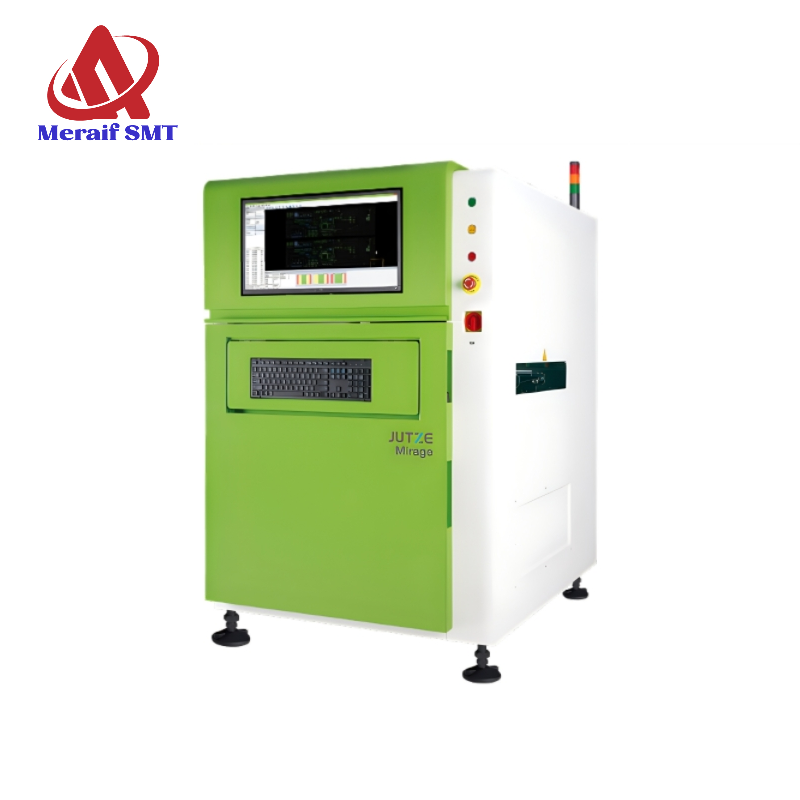

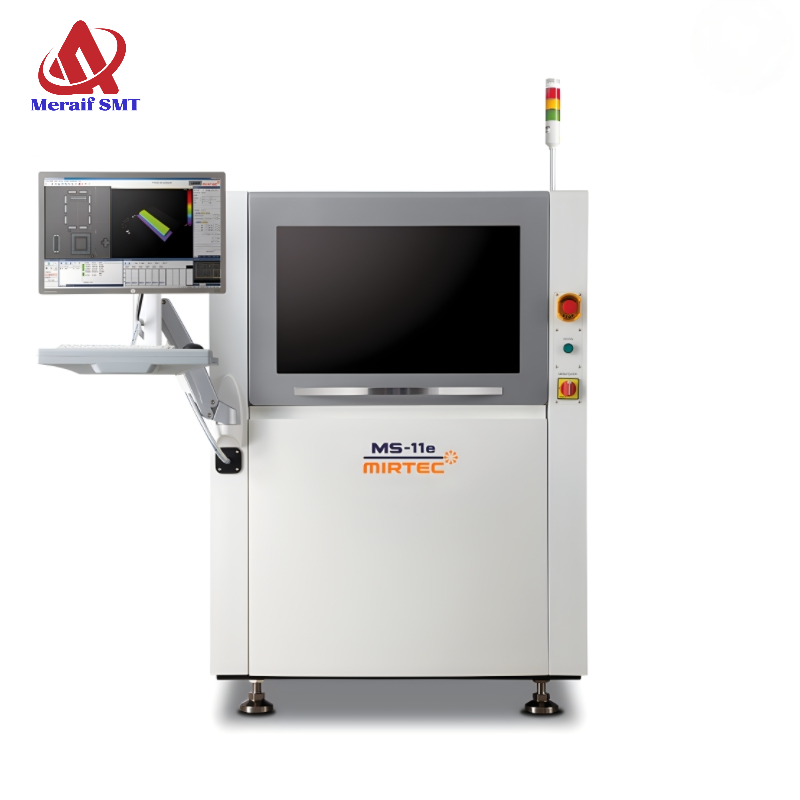

KOH YOUNG KY8030-2 SMT LINE SPI Picture Show:

EXHIBITION:

SMT LINE: