YAMAHA YSi-V 3D AOI SMT LINE AOI 3D Automated Optical Inspection Machine

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

YAMAHA YSi-V 3D AOI SMT LINE AOI Technical Parameters :

Model

YSi-V

Applicable PCB mm

Number of pixels

12 megapixels

5 megapixels

Type

12M TypeHS

12M TypeS

12M TypeDF

5M

Resolution

12μm

7um

12μm

7μm

12μm

18μm

Target items

Components status after mounting, components status and solder status after hardening

Power supply

3-Phase AC 200/208/220/230/240V/400/416V ±10% 50/60 Hz

Air supply source

0.4MPa or more, in clean, dry state

External dimension

L1,252mm x W1,498mm x H1,550mm (excluding projections)

Weight

Approx. 1,300kg

YAMAHA YSi-V 3D AOI SMT LINE AOI Details:

The impressive Yamaha YSi-V is a hybrid, automated, optical inspection (AOI) system offering high-speed, high-resolution image processing and image capture technology.

In one single unit, the Yamaha YSi-V can perform high-speed, high-resolution 2D inspection, height and tilt angle 3D inspection and diagonal angle image inspection via a 4-direction angled camera.

To achieve higher levels of operating speed, the Yamaha YSi-V features a 12 megapixel high-resolution camera, high-speed image processing technology, 3D inspection function, (that checks component height and tilt angle simultaneously), and a 4-direction angled camera employing exclusive image capture technology.

The YSi-V offers more than twice the inspection capacity/performance of the YSi-12 and introduces new features including full-HD LCD touch panel, “programming navigation” and new character recognition algorithms to improve operability.

Available with both 2D & optional 3D capability, with either 5 MP camera or as a high-end type with a 12 MP camera.

The 4V vision system enables angular inspection from four directions (45°, 135°, 225°, 315°). The Ysi V utilises 5 different inspection methods – laser, shape, colour, infrared & brightness, providing flexible and reliable imaging and inspection results.

The 3D imaging option reliably detects floating components that a 2D inspection system can miss. Detection is also improved where colour tones between board and components are similar or when there is interference between silk-screen and pattern. YSi-V 3D inspection can also detect the slope gradient and direction, and make pass/fail contour judgements.

Features

1.Enhanced 2D inspection capability with the adoption of newly developed high-speed, high-resolution image processing technology

2.New 3D inspection function that inspects component height and tilt angle in the field of vision simultaneously

3.Accommodates larger PCB sizes

4.Improved operability

5.Ensure consistent quality and operational efficiency

6.High flexibility

7.Low maintenance costs

8.Enhancing production efficiency for manufacturers

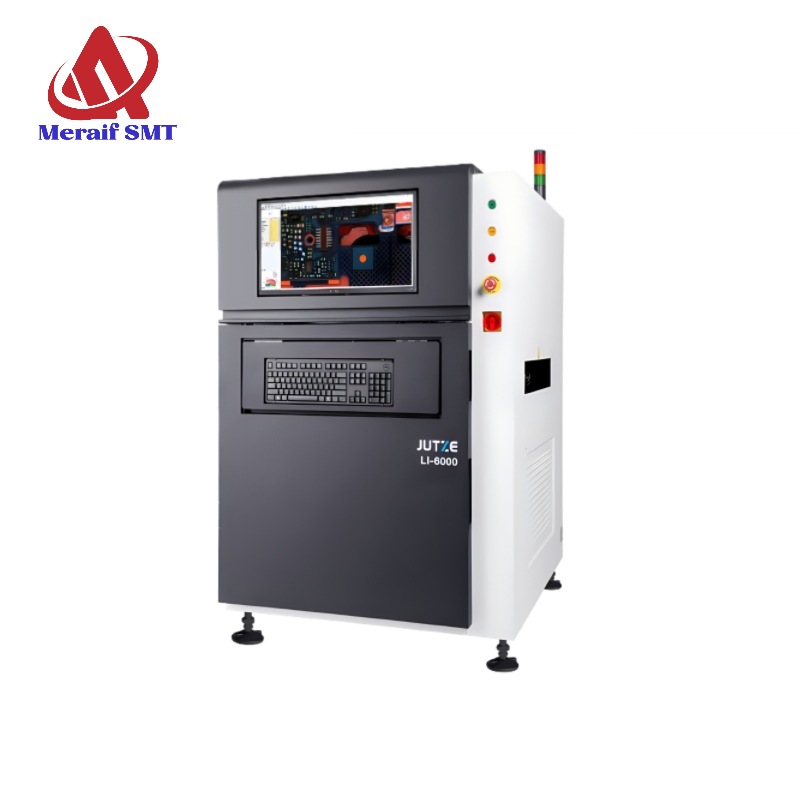

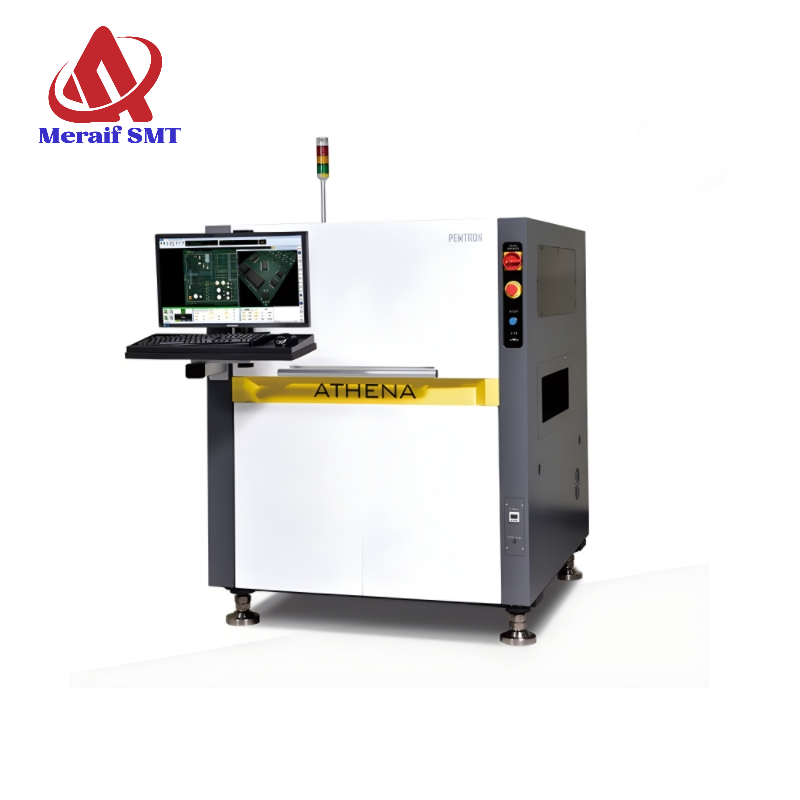

YAMAHA YSi-V 3D AOI SMT LINE AOI Picture Show:

EXHIBITION:

SMT LINE: