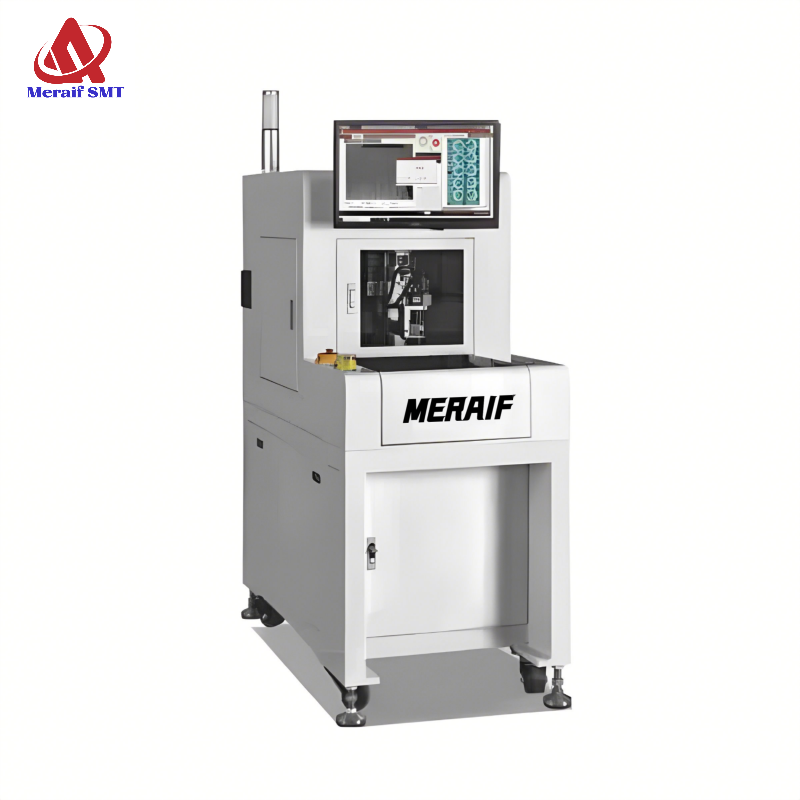

MERAIF MF-QL800A Automatic PCB Cutting Machine Board Cutter Machine PCB Separator PCB Board Cutting Machine

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

Manual PCB Depanelizer Manual PCB cutting machine Technical Parameters:

|

Model |

MF-QL800A |

|

Equipment size (L*W*H) |

1630*1640*1700mm |

|

Supply voltage/air pressure |

220V/50Hz 3KW 0.5-0.7Mpa |

|

Applicable product size |

300*350MM |

|

Programming method |

CCD |

|

Placement head |

Double head with swivel angle |

|

UPH |

1100/H |

|

Operation method |

Automatic loading and unloading |

|

Applicable pallet size |

Customized according to customer requirements |

|

Working height |

900±20mm |

|

Bad board identification function |

AOI detection function can be performed on the cutting position |

|

Equipment appearance |

Sheet metal main color (matte white) |

5. The cutting capacity requirement is to complete each small board within 3.5 seconds.

Equipment Action Flow Chart

1. Manually place the magazine loading frame on the loading machine preparation table;

2. After the board flows into the online machine, it automatically grabs the PCB board and cuts it into panels;

3. After cutting, the machine takes out the cut board and places it on the loading mold of the online plate placing machine;

4. When the loading mold of the placing plate machine enters the placing plate, dust is blown and vacuumed;

5. After dust removal is completed, enter the discharging position of the plating machine for plating;

6. Place each independent product into the empty tray through the placement head;

7. When one pallet is filled with products, another empty pallet will automatically be sent to the waiting position.

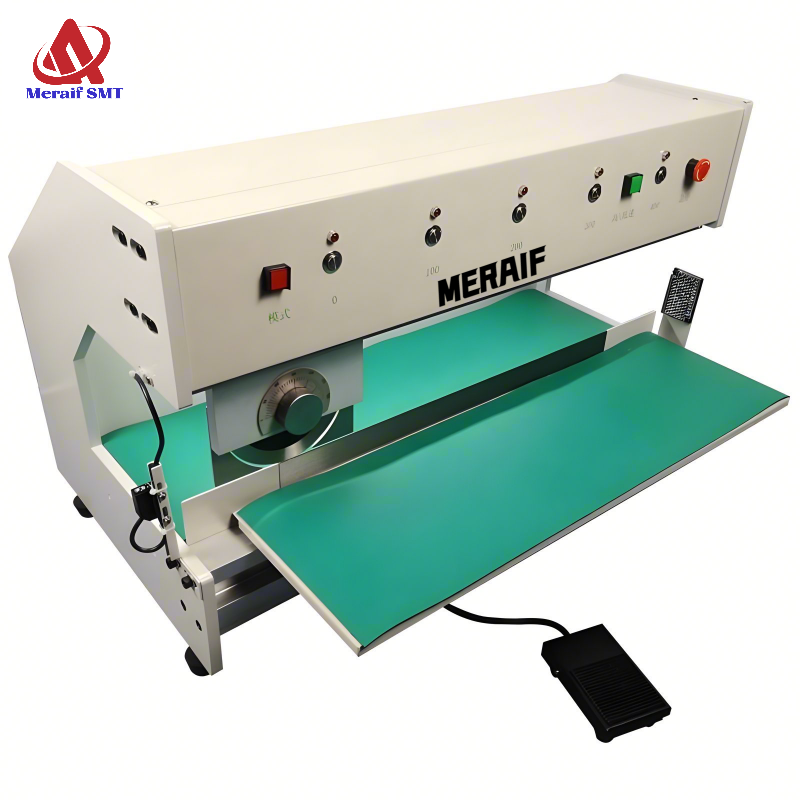

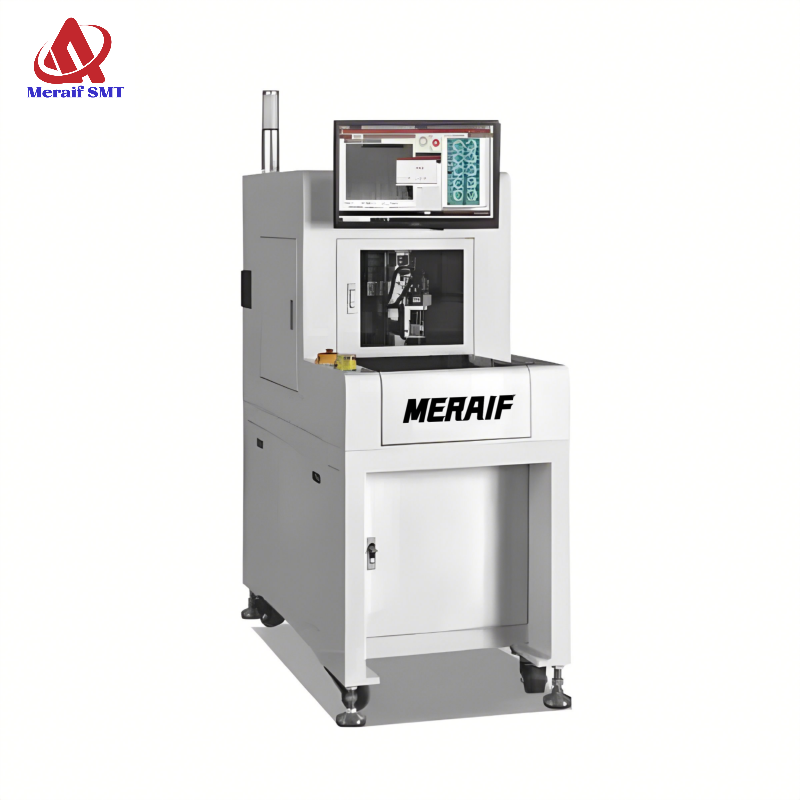

Manual PCB Depanelizer Manual PCB Cutting Machine Picture Show:

EXHIBITION:

SMT LINE: