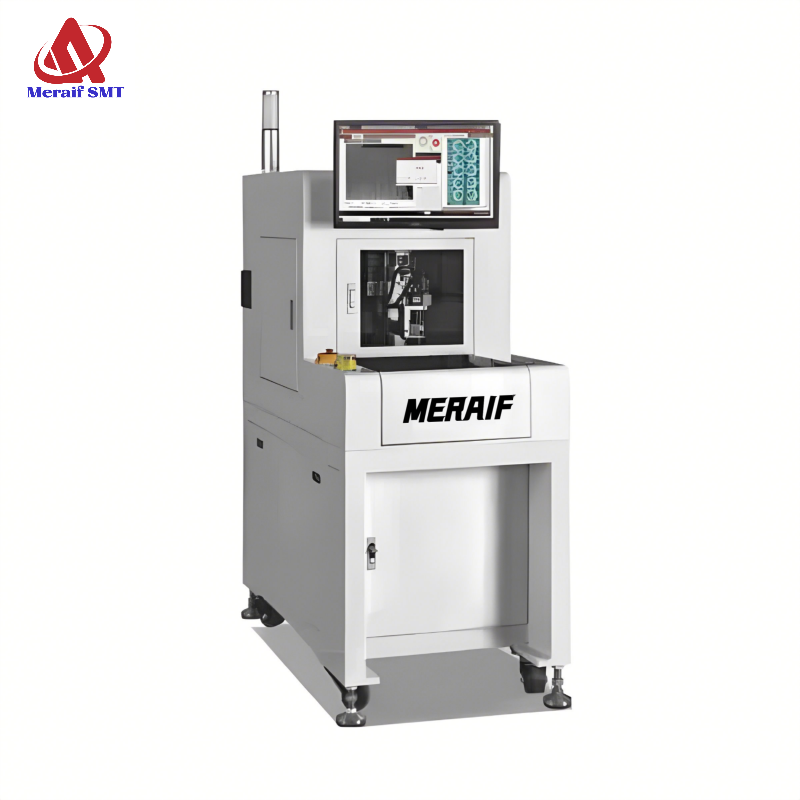

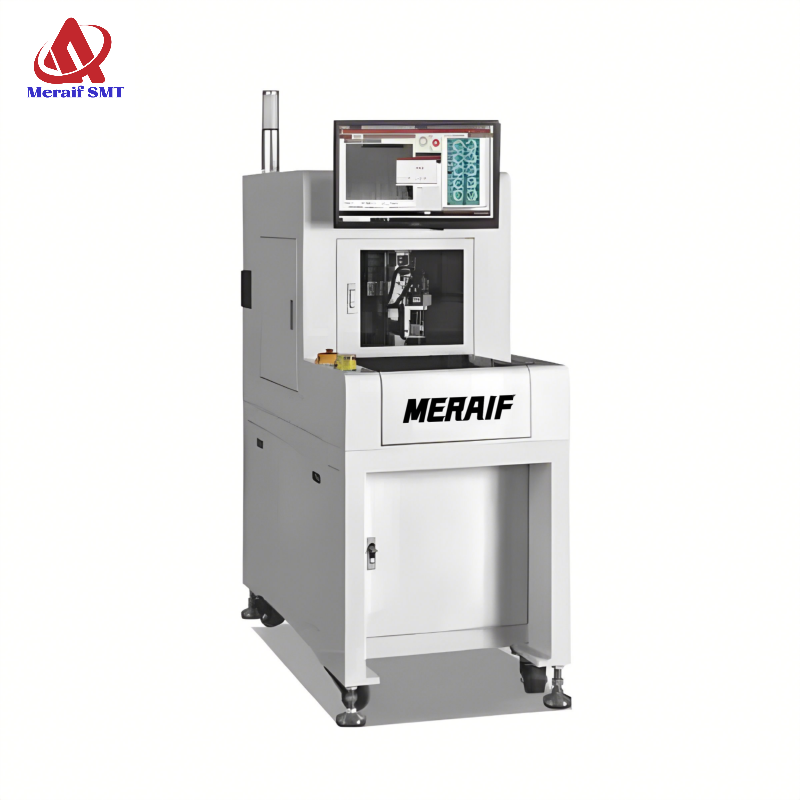

MERAIF MF-203 Manual PCB Cutting Machine Manual PCB Depanelizer

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

Manual PCB Depanelizer Manual PCB cutting machine Technical Parameters:

Model

MF-203

Dimensions

500x380x430mm

Cutting Stroke

400mm/300mm/200mm/100mm

PCB Thickness

1.0-3.2mm

PCB V Groove Thickness

0.25-2.0mm

Cutting Speed

Low/High mode.

Power

1P AC 110V/220V,50/60HZ

Weight

Approx.55KG

Manual PCB Depanelizer Manual PCB Cutting Machine Picture Show:

EXHIBITION:

SMT LINE: