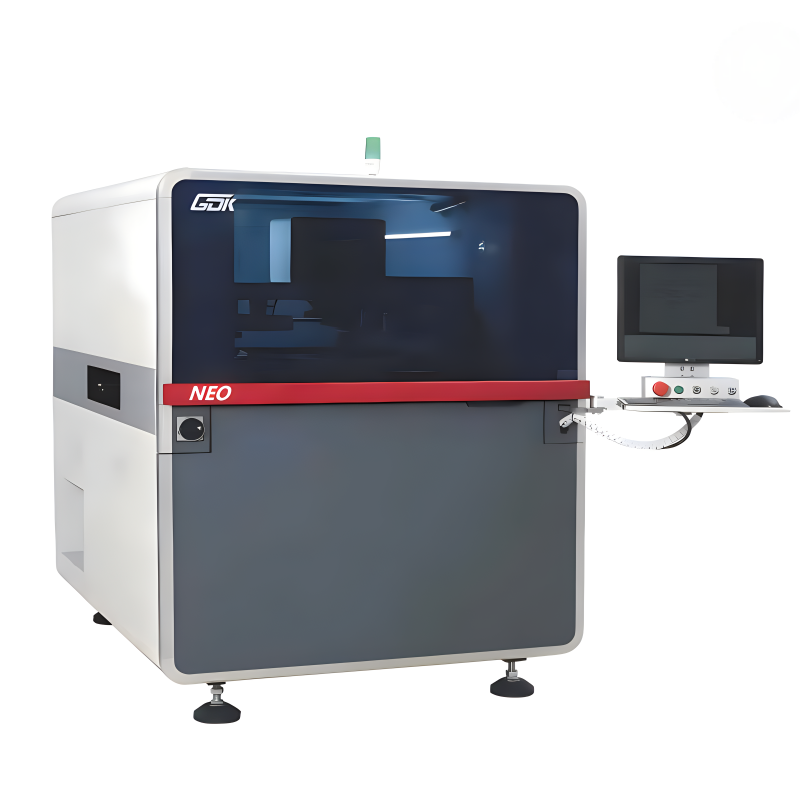

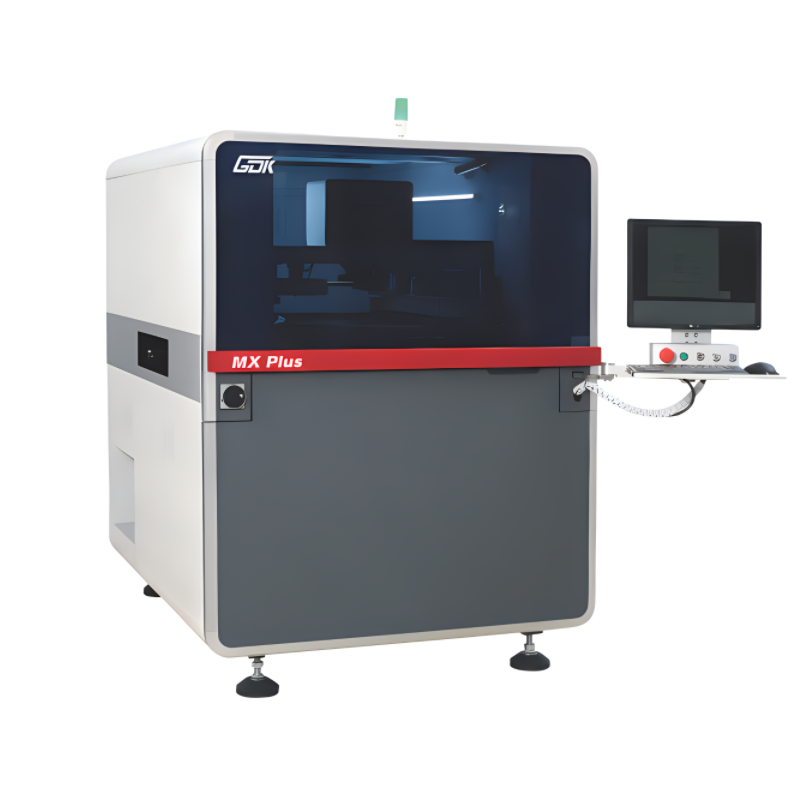

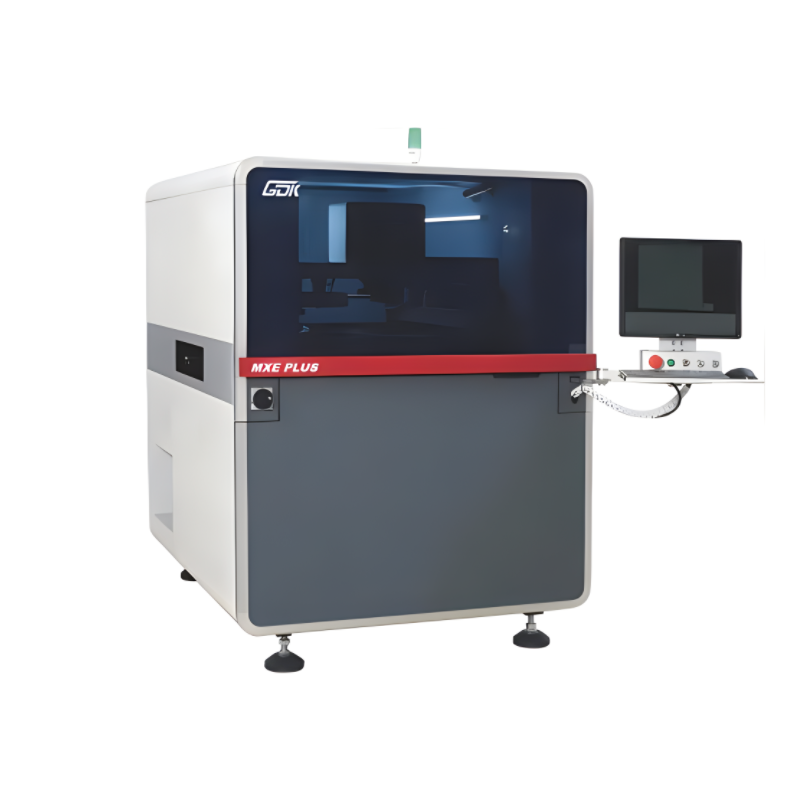

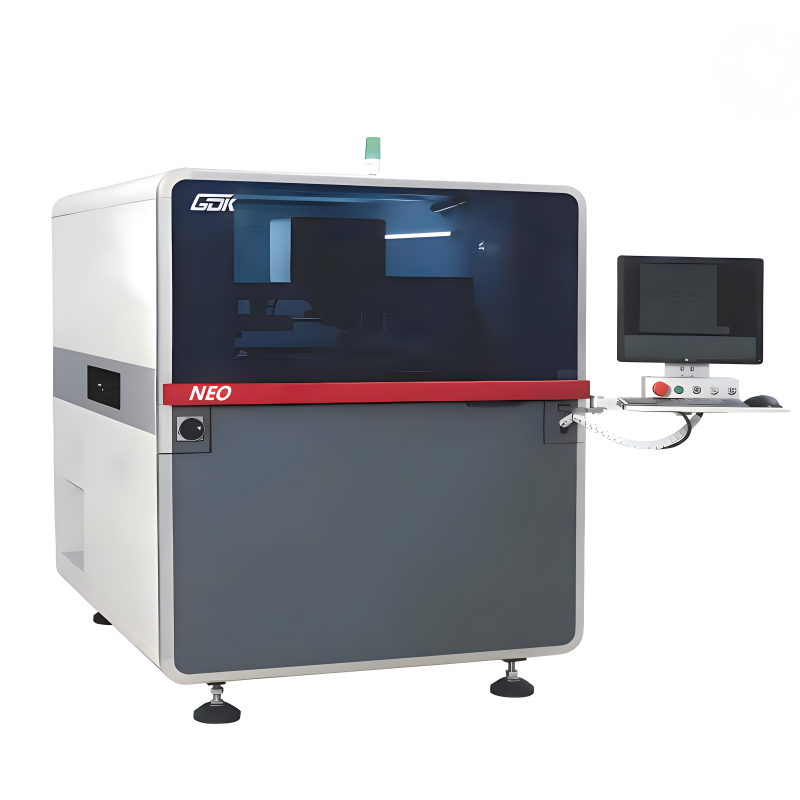

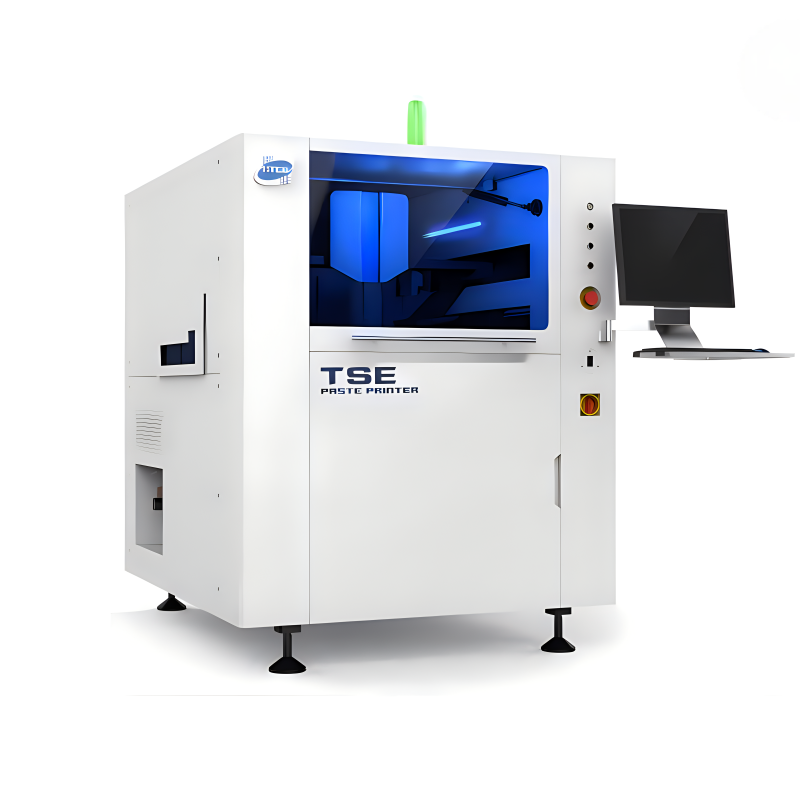

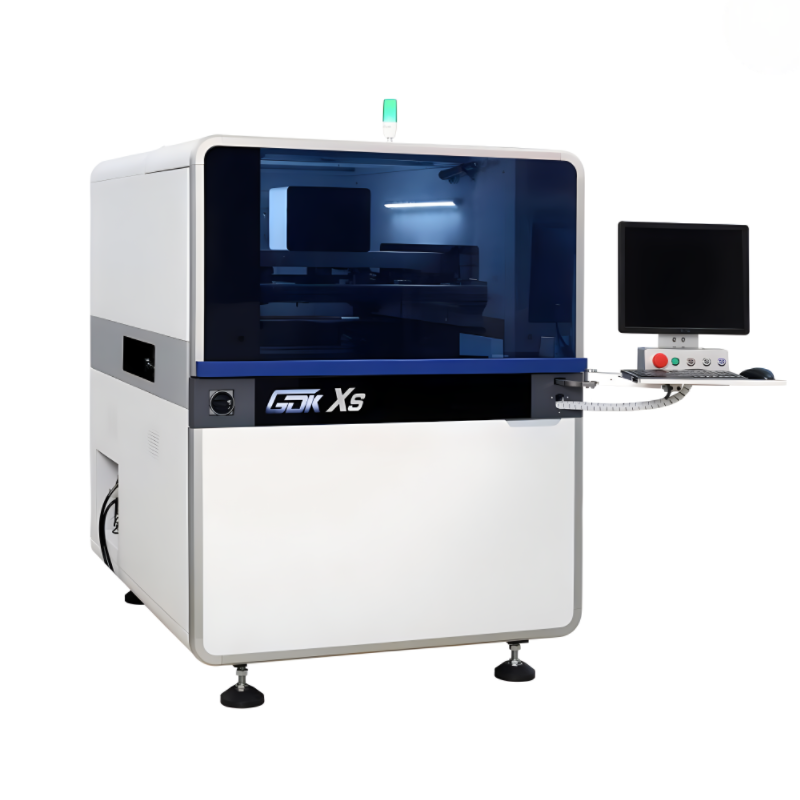

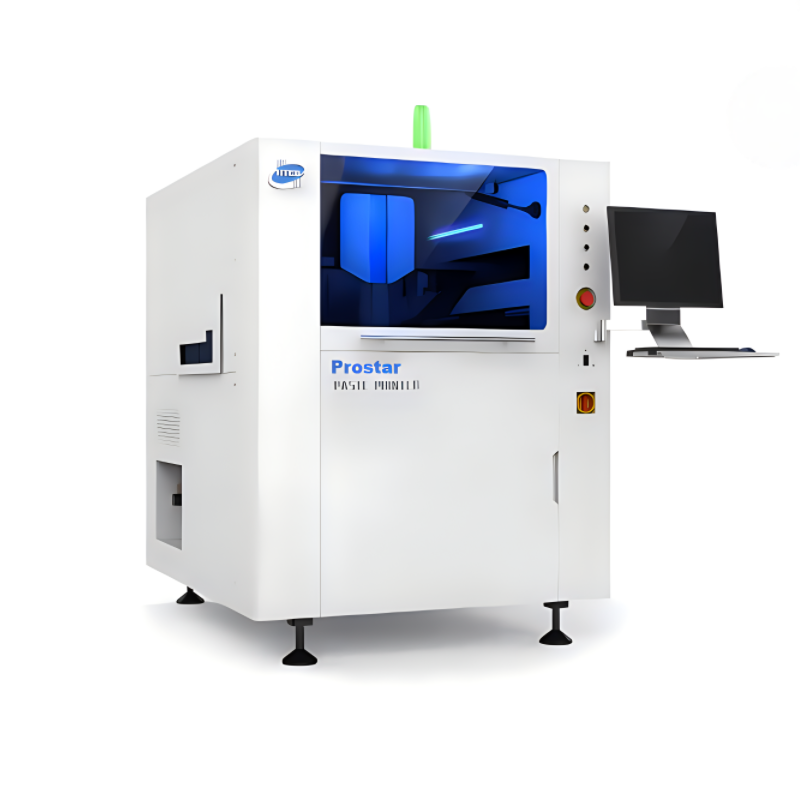

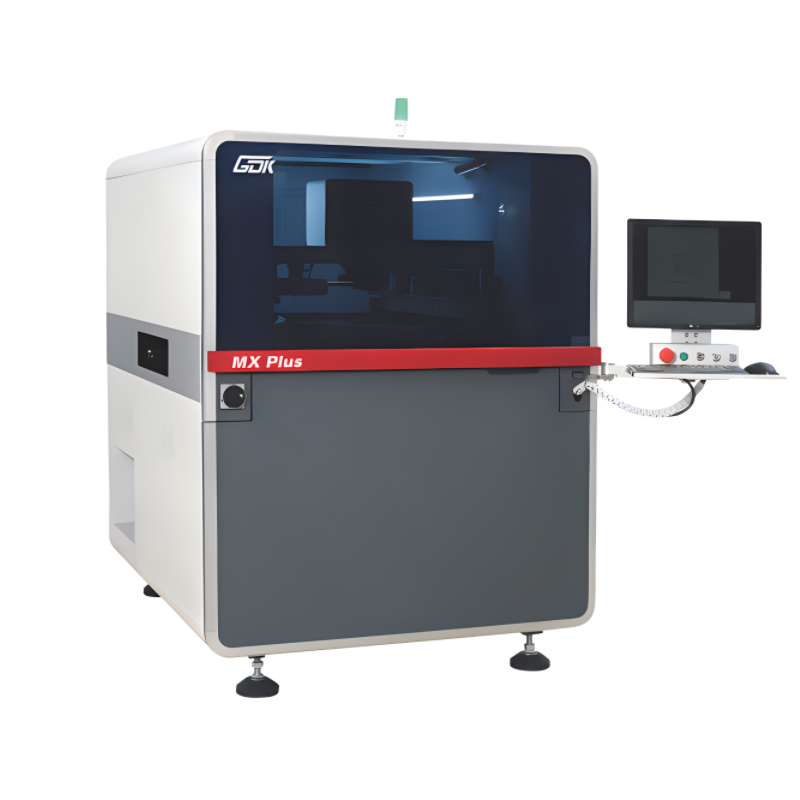

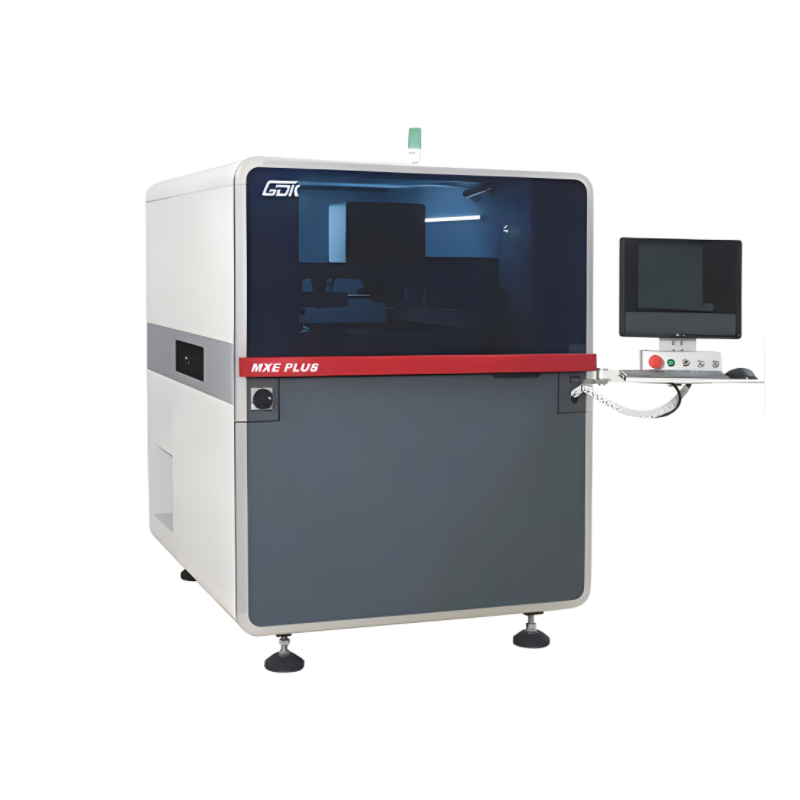

SMT Printer Machine GDK NEO SMT Stencil Printer Automatic Screen Printing Machine SMT Solder Paste Printer For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

GDK NEO Fully Automatic SMT Stencil Printer Technical Parameters :

Model

GDK NEO

PCB Parameter

Max. board size(X x Y)

650mm x 610mm

Min. board size(X x Y)

50mm x 50mm

PCB thickness Range

0.4mm~6mm

PCB Warpage

≤1%Diagonal

Max. board weight

5Kg

PCB edge clearance

Configuration to 3mm

PCB bottom clearance

20mm

Conveyor speed ( Max.)

1500mm/s(Max)

Conveyor height

900±40mm

Conveyor direction

L-R,R-L,L-L,R-R

Transfer mode

One stage orbit

PCB damping method

Proarammable flexible side pressure+ Adaptive PCB board thickness+

Edge lock base clamp. (optional: 1,Multipoint partial vacuum at the bottom;

2,Edge locking and substrate clamping)

Support method

Magnetic thimble + Equal high block.(Optional:1.vacuum suction cavity;

2.special workpiece fixture)

Printing parameters

Print head

Servo motrdrives prerisionscrew diven suspendedinteliet printing head

two independent diret motos

Stencil frame size

470x200~800x800 mm

Max. printing area(X x Y)

650x610mm

Squeegee Material / Angle

Steel squeegee/ Rubber squeegee(Angle 45°/50°/60° matching the

printing process)

Squeegee length

650mm (optional with length of 200mm-650mm)

Squeegee height

65±1mm

Squeegee thickness

0.25mm Diamond-like carbon coating

Print mode

Single or double squeegee printing

Demoulding length

0.02-12 mm

Print speed

0 ~ 200 mm/s

Print pressure

0.5kg - 10Kg

Print stroke

±275 mm(From the center)

Cleaning parameters

Cleaning system

1,front-mounted programmable cleaning liquid injection system;2,dry,

wet,vacuum three modes

Length of cleaning and wiping plate

650mm

Optical System

Field of view

8x6mm

Printing table adjustment range

X:±7.0mm,Y:±8.0mm,θ:±2.0°

Fiducial Types

Standard Fiducial type ( Circle, triangle, square, diamond, cross)

(SMEMA standard),solder pad/openings

Vision methodology

Independent camera,upwards/downwards imaging vision system,

geometric matching location

Performance parameters

Machine Alignment repeatability

±10.0μm @6 σ,Cpk ≥ 2.0

Full process repeatability

±15.0μm @6 σ,Cpk ≥ 2.0

Core Cycle time

7.5s(Exclude printing and cleaning)

Product changeover time

<5min

Equipment

Power supply

AC220V±10%,50/60HZ,15A

Air supply

4~6Kg/cm²

Gas Consumption

About 5L/min

Operating system (OS)

Windows 7(Optional WIN10)

External dimension

1,540(L) x 1,220(W) x 1,660(H)mm(Without light,monitor and

keyboard)

Machine weight

Appro.1230Kg

User Permission

Different users have different permissions (fingerprint identification

entering / password input)

Environment temperat

23±3°C

Relative humidity

45~70%RH4

GDK NEO Fully Automatic SMT Stencil Printer Details:

The structure of NEO is simple and reliable,accurate positioning and easy to adjust, aimed at high end application of SMT, especially for LED mini. It can quickly achieve different thickness of the PCB board PIN pin height adjustment of the automatic adjustment. The spray nozzle makes the cleaning liquid evenly sprinkled on the wiping paper, and the arc-shaped rubber wipe board is soft, antiwear and antirust, clean thoroughly bidirectionally, and can be used for dry cleaning, wet wiping, wet cleaning, reciprocating cleaning and other functions..

Alignment precision∶±10.0micron/μm@6σ,Cp≥2.0

Printing precision∶ ±15.0micron/μm@6σ,Cp≥2.0

GDK NEO Fully Automatic SMT Stencil Printer Picture Show:

Exhibition:

SMT LINE: