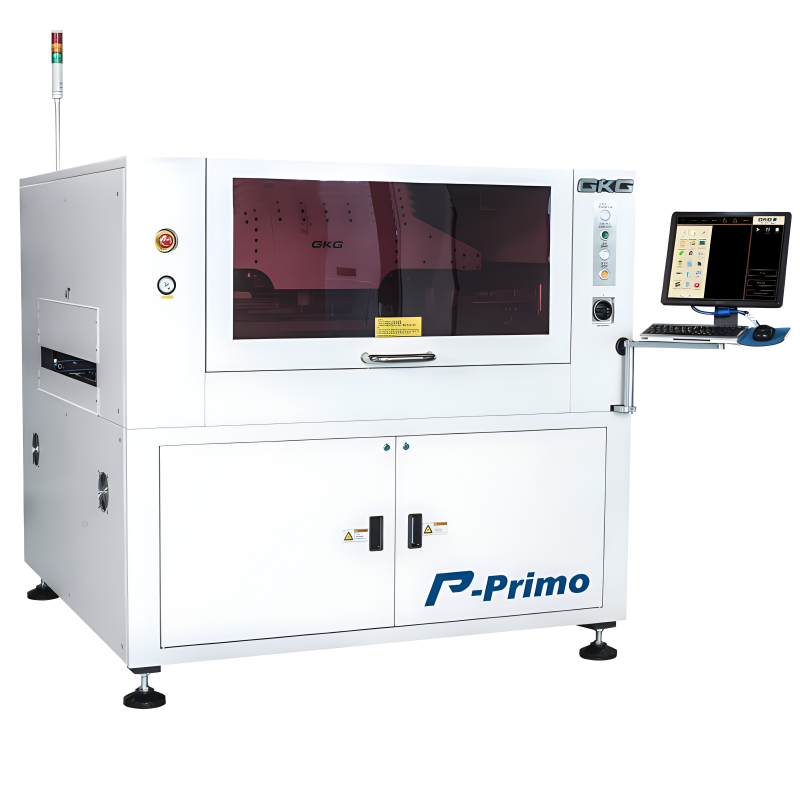

SMT Printer Machine GKG P-PRIMO SMT Screen Printer Automatic Stencil Printer Machine SMT Solder Paste Printer For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

GKG P-PRIMO Fully Automatic SMT Screen Printer Technical Parameters :

Model

P-Primo

Item

Performance

Machine Alignment Capability

2Cmk @ ±12.5@4σ

Process Alignment Capability

2Cpk @ ±25@4σ

Core Cycle Time

<12 secs(excluding printing & cleaning time)

Product Changeover Time

<5 secs

New Product Set-up Time

<10 secs

Max. Size (L x W)

850mm x 610mm

Min. Size (L x W)

100mm x 65mm

Thickness

0.4~8mm

PCB Thickness Adjustment

Automatic

PCB Max. Weight

10kg

PCB Edge Clearance

3.5mm

PCB Bottom Clearance

23mm

PCB Warpage

Max 1% diagonally

Clamping Method

Retractable top clamp, motor controlled side clamp

Support Method

Magnetic support pins, bars, blocks, vacuum suction

Conveyor Direction

L to R, R to L, R to R, L to L (software control)

Conveyor Height

900 ± 40mm

Conveyor Speed (max.)

1,500 mm/s

Conveyor Width Adjustment

Automatic

Hardware

LCD Monitor, Mouse & Keyboard

Operating System (OS)

Windows 7 or Higher

Control Method

Industrial PC controlled

I/O Interface

SMEMA Standard

Stencil Frame Size (L x W)

Adjustable, 737mm x 737mm to 1,100mm x 850mm

Print Gap (snap-off)

0~20mm

Printing Table Adjustment Range

X:±10mm, Y:±10mm, :±2°

Print Speed

5~150mm/s

Squeegee Pressure

0.5~10kg (program control)

Squeegee Type

Std.: Metal, Option: Rubber

Squeegee Angle

Std. 60º, Option 45º, 50º, 55º

Cleaning System

Auto wet, dry, vacuum (Software select)

Power Supply

AC220V ± 10% 50/60Hz

Power Consumption

3kW

Air Supply

4~6Kgf/cm2

Dimension (excluding signal tower)

1,590 (L) x 1,608(W) x 1,530mm (H)

Machine Weight

1,400kg

Field-of-View (FOV)

8mm x 6mm

Fiducial Types

Circle, triangle, square, diamond, cross

Fiducial Size

0.5~4.0mm

Vision Methodology

CCD camera look up & down

2D Inspection

Max. 100 windows to inspect missing & insufficient (std.)

GKG P-PRIMO Fully Automatic SMT Screen Printer Details:

P-PRIMO

Screen-Printer

JUKI’s mid-size screen printer P-PRIMO aims at medium-format printed ciruit boards with sizes of up to 850 × 610 mm. The machine is delivered with a well-structured, easy to use software, which allows the construction of a production programme in less than 8 minutes. Further functions that are included with delivery: automatic stencil cleaning, 2D solder paste inspection, top and side clamping and many more!

Long-Lasting Accuracy

The machine table and squeegee carrier are cast, not welded. Therefore guaranteeing high torsion resistance and ensuring print accuracy to remain unchanged for years.

High Flexibility

P-PRIMO and JUKI Pick and Place machines as well as JUKI Reflow Soldering Ovens enable needs-based, individual SMT line solutions.

Optimised Operation and Maintenance

The straightforward constructed Windows-based operator software enables a fast initial training and swift programme construction. A programme change lasts about two minutes, a new publication approximately ten minutes. Furthermore large covers and service doors allow for easy access to all assemblies.

GKG P-PRIMO Fully Automatic SMT Screen Printer Picture Show:

Exhibition:

SMT LINE: