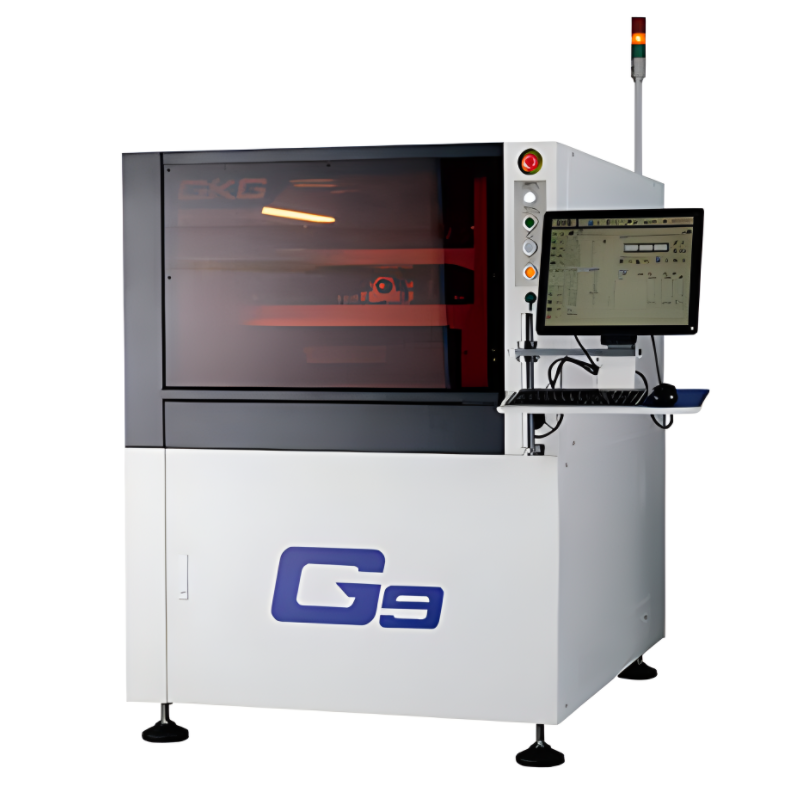

SMT Printer Machine GKG G-Titan SMT Stencil Printer Automatic Screen Printing Machine SMT Solder Paste Printer For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

GKG G-Titan Fully Automatic SMT Stencil Printer Technical Parameters :

Model

G-TITAN

PERFORMANCE

Machine Alignment Capability

CPK≥2.0,±10@6σ

Process Alignment Capability

CPK≥2.0,±18@6σ

Core Cycle Time

< 8.5 secs(excluding printing & cleaning time)

Product Changeover Time

< 3 mins

New Product Set-up Time

< 10 mins

BOARD HANDLING

Max. Size (L x W)

510 mm x 510 mm

Min. Size (L x W)

50 mm x 50 mm

Thickness

0.4~6 mm

PCB Thickness Adjustment

Automatic

PCB Max. Weight

5 kg

PCB Edge Clearance

3 mm

PCB Bottom Clearance

23 mm

PCB Warpage

Max. 1% diagonally

Clamping Method

Auto retractable top clamp, motor controlled side clamp

Support Method

Magnetic support pins, bars, blocks, vacuum suction

Conveyor Direction

L to R, R to L, R to R, L to L(software control)

Conveyor Height

900 ± 40 mm

Conveyor Speed

1,500 mm/s

Conveyor Width Adjustment

Automatic

PRINTING PARAMETERS

Stencil Frame Size (L x W)

Adjustable, 470 mm x 370 mm to 737 mm x 737 mm

Print Gap (snap-off)

0~20 mm

Printing Table Adjustment Range

X: ±10 mm, Y: ±10 mm : ± 2°

Print Speed

10~200 mm/s

Squeegee Pressure

0.5~10kg (program control)

Squeegee Type

Std.: OPC Squeegee 300 mm, 450 mm & Metal Squeegee 520mm. Option: Rubber

Squeegee Angle

Std. 60°, Option 45°, 50°, 55°

Cleaning System

Auto wet, dry, vacuum (Software select)

FACILITIES REQUIREMENT

Power Supply

AC220V ± 10% 50/60Hz

Power Consumption

3kW

Air Supply

4 ~ 6Kgf/cm²

Air Consumption

5L/min

Dimension (excluding signal tower)

1,240 mm (L) x 1,560 mm (W) x 1,490 mm (H)

Machine Weight

1,200kg

OPERATOR INTERFACE

Hardware

LCD Monitor, Mouse & Keyboard

Operating System (OS)

Windows 10

Control Method

Industrial PC controlled

I/O Interface

SMEMA Standard

OPTICAL SYSTEM

Field-of-View (FOV)

10mm x 8mm

Fiducial Types

Circle, triangle, square, diamond, cross

Fiducial Size

0.5~4.0 mm

Vision Methodology

Digital CCD camera look up & down

2D Inspection

Max.100 windows to inspect missing & insufficient (std.)

STANDARD FEATURES

Auto paste replenishment (OPC)

Paste rolling diameter monitoring system (OPC)

OPC squeegee assembly (2 pairs 300mm & 450mm)

Stencil Lock (QPC)

Stencil apertures inspection system (QPC)

OPTIONS

SPI closed-loop

Auto glue dispensing

Temperature, humidity monitoring & display with aircon unit

Internal/External barcode scanner for PCB traceability

Handheld barcode scanner for stencil, solder paste, squeegee traceability

MES system integration (For Ind. 4.0)

2 machines in series for higher output

2 machines back to back for dual lane SMT line

GKG G-Titan Fully Automatic SMT Stencil Printer Details:

JUKI's new G-TITAN is equipped with premium quality functions empowering the JUKI Screen-Printing Solution on its path to Industry 4.0 and “Lights-Out-Manufacturing”. Ease of use is provided due to a brand new GUI – Graphical User Interface – which is operated via touch screen. G-TITAN supports circuit boards of sizes up to 510 × 510 mm and therefore addresses its demands towards the mid-size segment. Innovative novelties such as the Opti Paste Control – OPC – as well as the Quality Print Control – QPC – represent useful individual functions to achieve optimised paste consumption, higher level of automisation and avoidance of printing errors during the screen-printing process.

Opti-Paste Control (OPC) - Get Ready For Light-Out Manufacturing

Auto Paste Dispensing - The paste is automatically dispensed across the entire squeegee length, maintaining at 15mm rolling diameter, adopting the common 500 grams' solder paste jar. Completely eliminates the wastage of solder paste overflowing to the sides of squeegee.

Paste Rolling Diameter Monitoring System - Tracing solder paste rolling diameter in real time and trigger the auto dispensing if it falls below 10mm. Completely eliminate insufficient solder paste on stencil and keep the paste rolling speed within optimum range to achieve best printing result.

OPC Squeegee - Retainers at both sides can be adjusted to the exact length of the PCB, enabling solder paste to be retained within the PCB length to obtain a clean sweep. Possess absolute control over desired printing area, to achieve best printing quality.

Quality Print Control (QPC) - Nothing Is More Important Than a Good Print

Stencil Aperture Inspection System - Using panel light installed at the top and CCD camera below to inspect stencil apertures. It automatically detects the clogging of stencil apertures to eliminate poor quality stencil being used, ensure quality printing right from the start.

The Stencil Flattener & PCB Clamper - The Stencil Flattener sucks the stencil firmly on both sides of the conveyor during printing cycle. To eliminate stencil vibration by having firm contact with PCB. The PCB clamper is a combination of retractable top clamp and motor controlled side clamp, uniquely designed by GKG (patented). With these standard features, all of today's available and challenging substrates can be securely clamped and print to the highest quality.

G-TITAN Screen Printer Options

Ready for Industry 4.0 - Through machine status, parameters can be uploaded automatically. Designed to support customers' advancement towards Industry 4.0 intelligence production, G-Titan provides seamless connection with users' MES system, enhancing product traceability and maintenance needs.

SPI Close-loop Connection - With SPI close-loop system, machine will automatically adjust and correct the print deposits based on the feedback given with regards to poor printing quality. This will facilitate improved print quality and production efficiency, by forming a complete printing feedback system.

Back to Back (BTB) - 2 Machines back to back is a perfect match to all dual lane SMT lines. The machines can be operated independently of each other, running different types of product.

Positive Dispenser Pump (PDP) - Integrates two technologies into one platform. The new PDP option accurately dispenses an additional medium of material (Paste or Glue) in dot, line and area patterns after the printing process. Ideal for cusla 1 iers with mixed technology boards as this option maximizes production flexibility, minimizes floorspace and reduces capital expenditures.

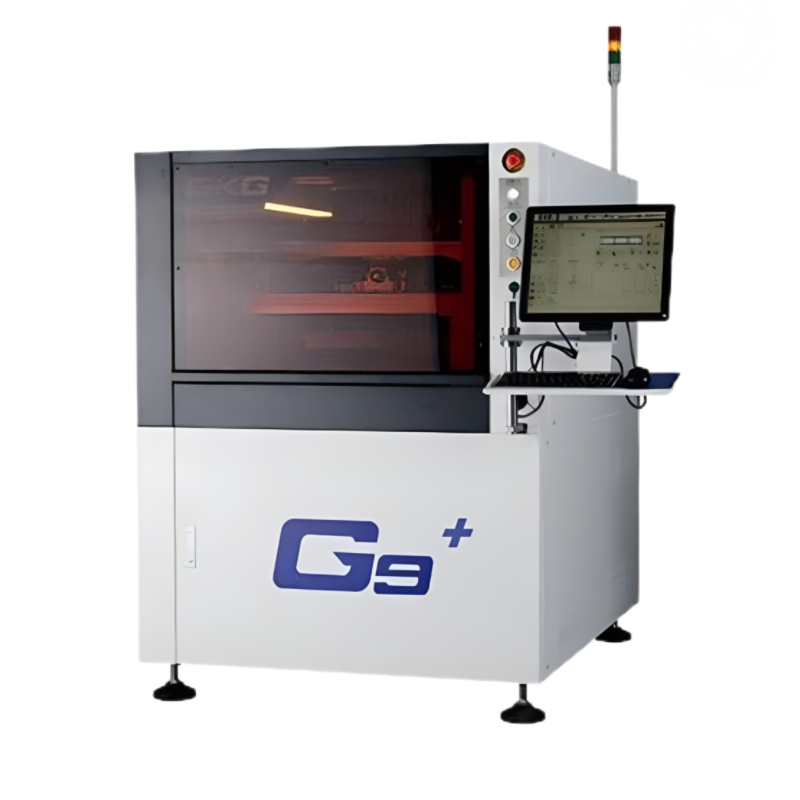

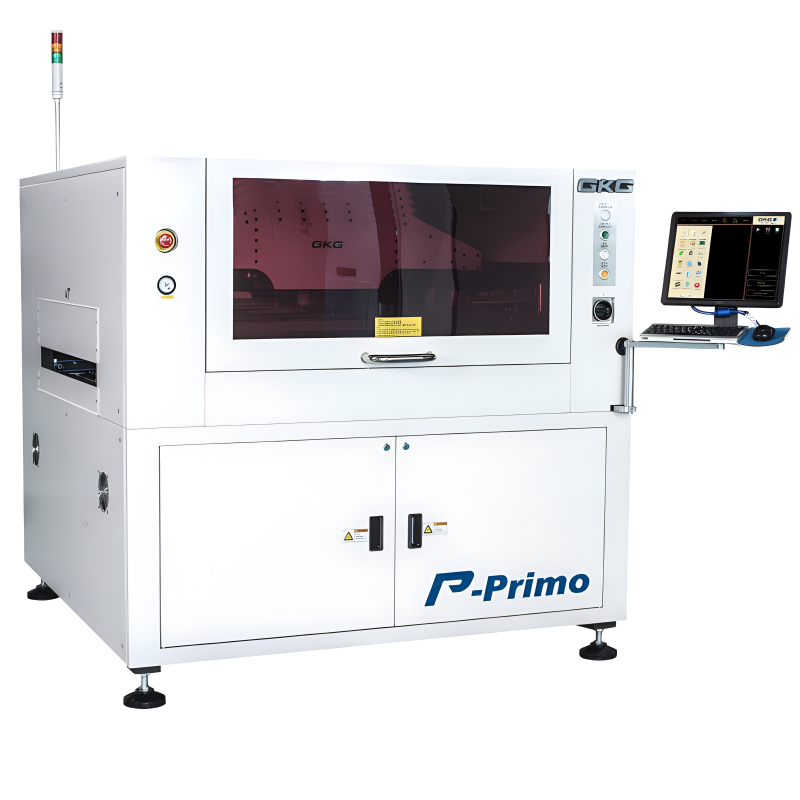

GKG G-Titan Fully Automatic SMT Stencil Printer Picture Show:

Exhibition:

SMT LINE: