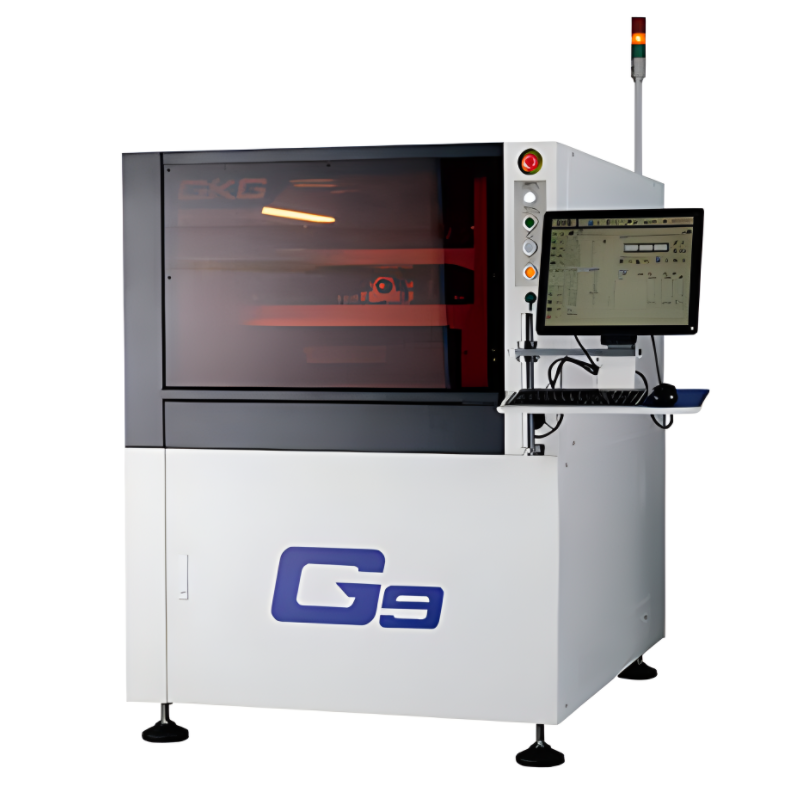

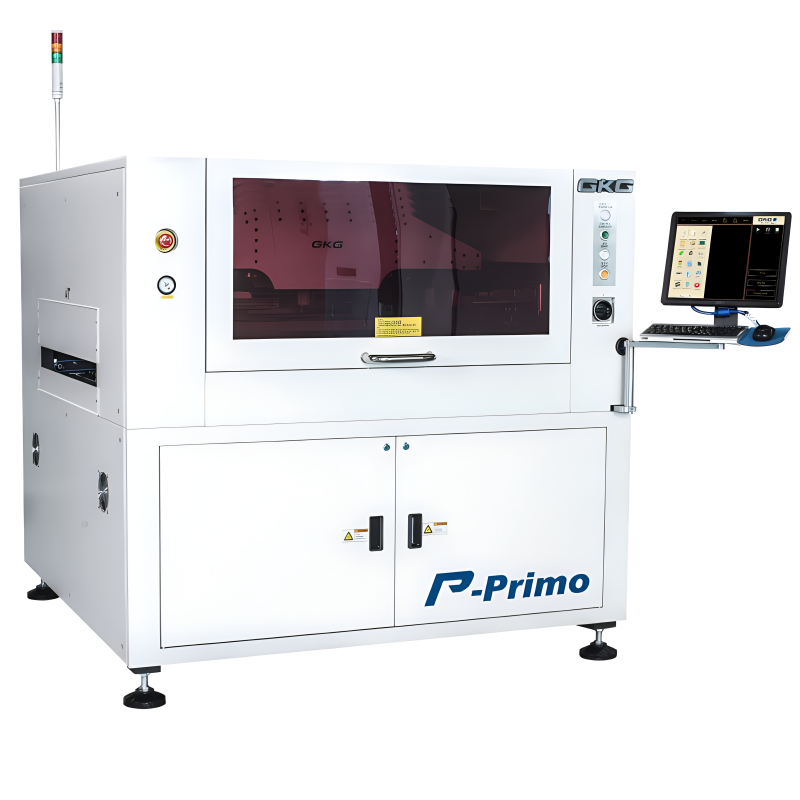

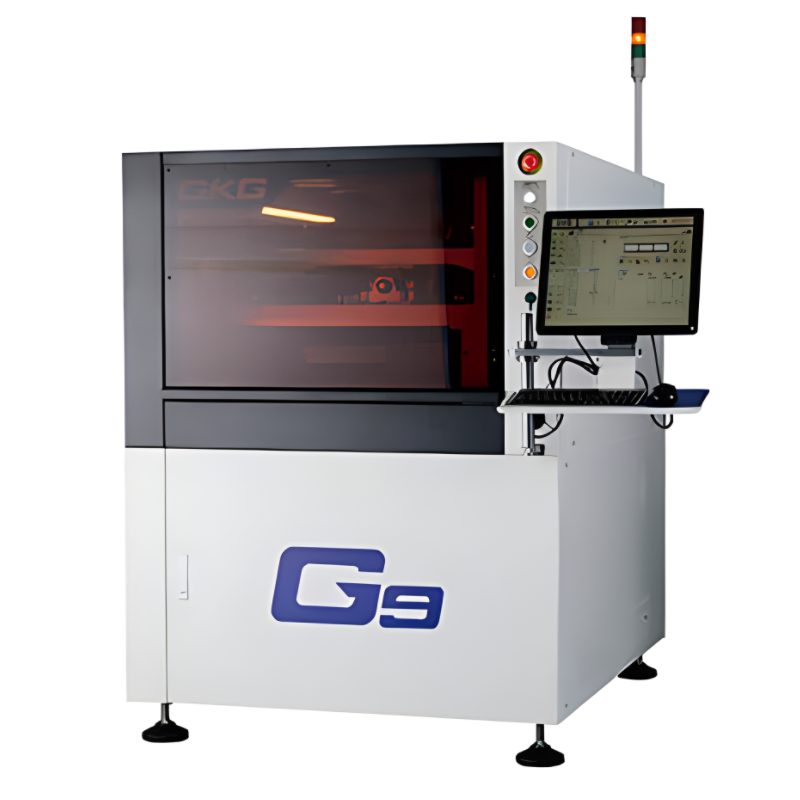

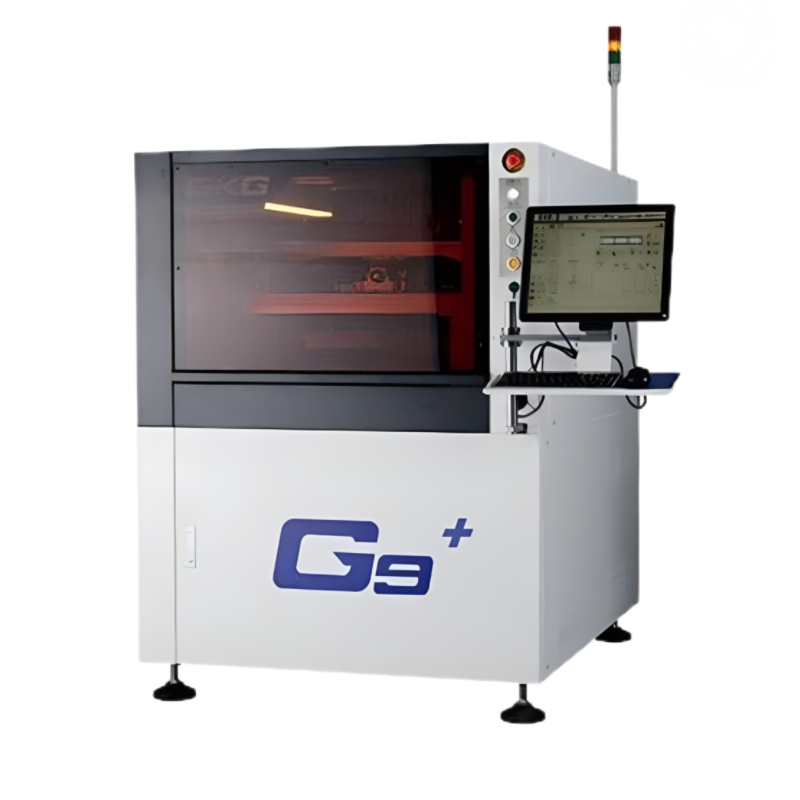

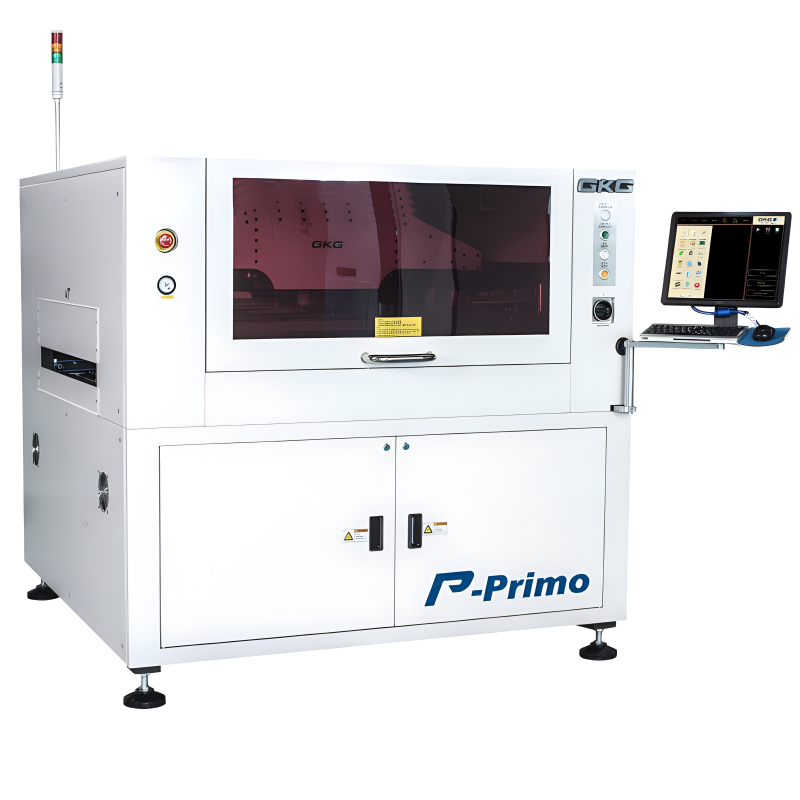

SMT Printer Machine GKG GSE SMT Stencil Printer Automatic Screen Printing Machine SMT Solder Paste Printer For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

GKG GSE Fully Automatic SMT Stencil Printer Technical Parameters :

Model

GSE

Stencil Frame

Min. size

370*370mm

Max. size

737*737mm

PCB

Min. size

50*50mm

Max. size

400*340mm

PCB Thickness

0.4–6 mm

PCB Bottom Clearance

15 mm

GAP (snap off)

0 – 20 mm

Conveyor Height

900 ±40 mm

Conveyor Direction

L>R, R>L, R>R, L>L (software controlled)

Conveyor Width Adjustment

Auto

Conveyor Speed

1500mm/s(MAX), Program Control

Transfer method

One stage transport rail

I/O Interface

SMEMA

PCB Location

Support System

magnetic pin, support block, and manually adjust the working platform

Clamping System

over the top and flexible side clamping

Squeegee Pressure

0 – 10 kg

Print Speed

10 – 200 mm/s

Cleaning System

Auto wet/dry/ vacuum (3 ways)

CCD FOV

8 x 6 mm

Fiducial Alignment

Auto

Printing Mode

Single or double squeegee printing

Squeegee Type

Rubber squeegee/steel squeegee (angle 45/55/60)

Vision

look up/down system, digit camera, Geometric matching positioning

Machine Performance

Repeat Position Accuracy

±0.01 mm

Printing Accuracy

±0.025 mm

Cycle Time

< 8 s

(exclude printing & cleaning time and camera)

Machine Operating Requirements

Air Supply

4 – 6 bar

Power Supply

AC, 220 V ± 10%, 50/60 Hz, single phase

Power Consumption

3 kW

Operating Temperature

-20℃~+45℃

Operating Humidity

30 – 60 %

Printer Control

PC controlled

Machine Dimensions

1158 x 1362 x 1463 mm (L x W x H)

Operating System

Windows XP or higher

Machine Weight

approx. 1000 kg

The specific description may change with technological development and progress. If the product does not match, the actual product shall prevail.

GKG GSE Fully Automatic SMT Stencil Printer Details:

GKG GSE automatic stencil printer is using uniform ring light and high brightness coaxial light, with promise brightness adjustment function, then all types of Mark points can be well recognized (Including the rugged Mark points), applicable for tin plating, coppering, gold plating, tin spraying, FPC and other types PCB with of different colors. With GKG patent mathematical model, able to ensure high accuracy. GKG GSE full-auto stencil printer cleaning system equipped with three cleaning methods: dry cleaning, wet cleaning, vacuum. which can be combined to use. It can also be cleaned by manual if customer do not need to use automatic cleaning to reduce the cleaning time and improve production efficiency. The newly wiping system ensures full contact with the stencil, increased vacuum suction can effectively eliminate the remaining paste in the mesh, which can achieve effective automatic cleaning function. GKG GSE solder paste printer CCD part and cleaning system is separated, when CCD working, CCD part independently move to reduce the servo motor load and improve the machine speed and accuracy. GKG GSE smt printer's high adaptability steel mesh frame clamping system able to print all kinds of size screen frames, and quickly change models during production line.

GKG GSE Fully Automatic SMT Stencil Printer Picture Show:

Exhibition:

SMT LINE: