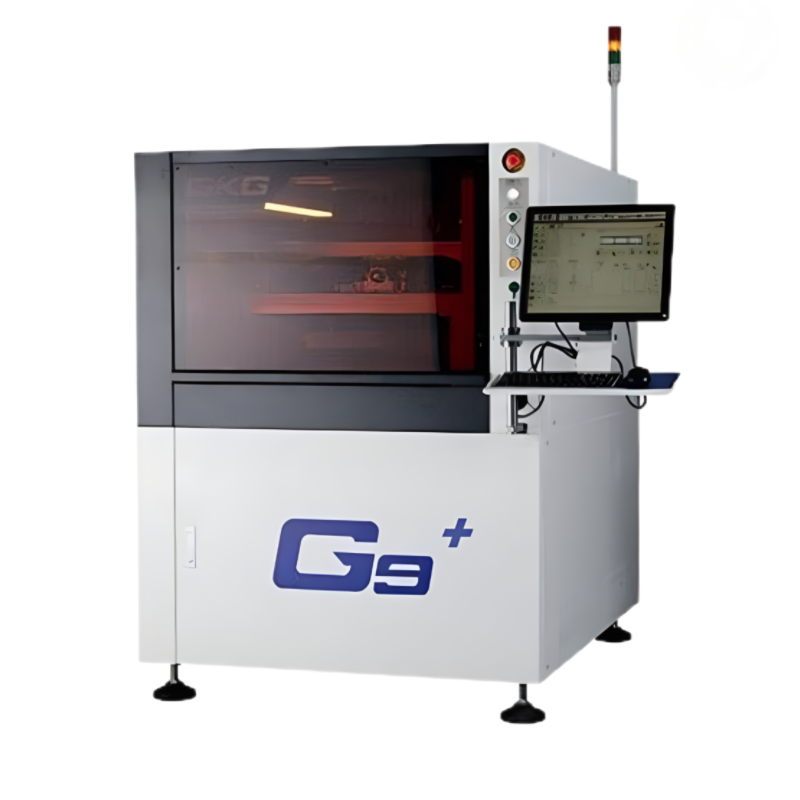

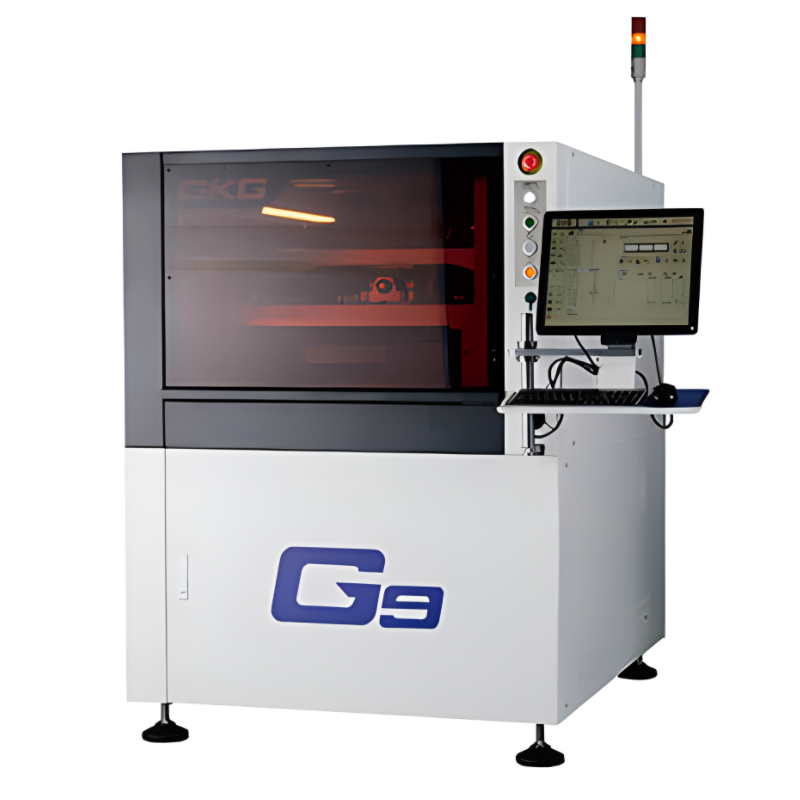

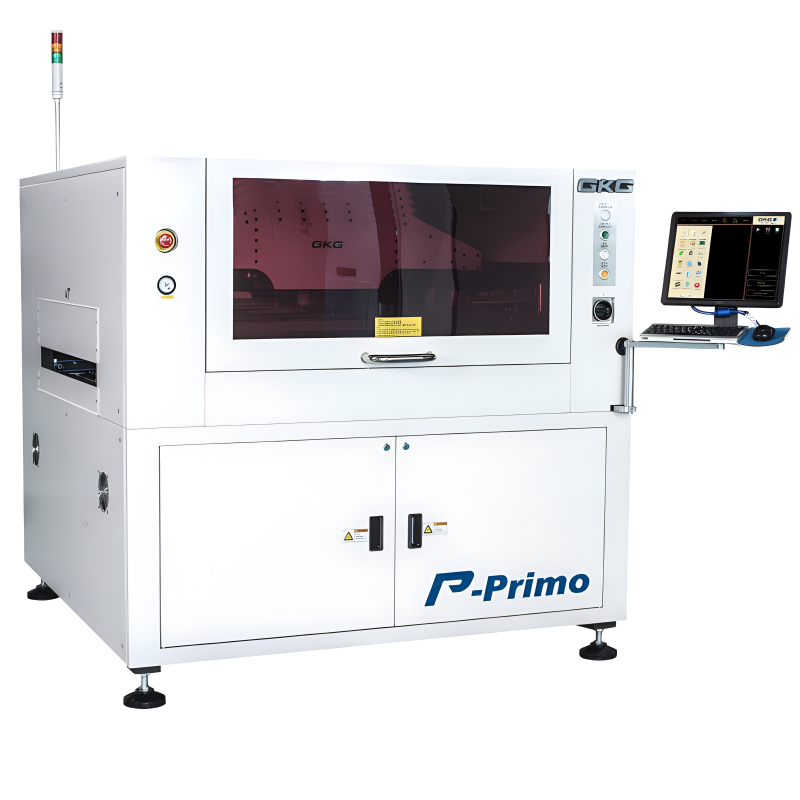

SMT Printer Machine GKG G9 SMT Stencil Printer Automatic Screen Printing Machine SMT Solder Paste Printer For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

GKG G9 Fully Automatic SMT Stencil Printer Technical Parameters :

Bare board:

Max bare board size(XxY)

400*340mm

Min bare board size(XxY)

50*50mm

Bare board thickness

0.4~6mm

Bare board Max weight

3Kg

Bare board edge clearance

2.5mm

Bare board height

15mm

Transport height

900 ± 40mm

Transport speed

Segment control 1500mm/s(Max)

Transport method

One stage transport guide

Bare board clamping

Automatic retractable upper tablet

flexible side clip

Vacuum adsorption function

Bare board support Method

Magnetic Thimble

Contour block

Manually adjust the jacking platform

Printing parameters:

Printing Snap-off

0-20mm

Max printing area (X x Y)

530*340mm

Printing mode

Single or double doctor blade printing

scraper type

Rubber Scraper/Steel Scraper (Angle 45/55/60)

Printing speed

10~200mm/sec

Printing pressure

0.5~10Kg

Template frame size

370*370mm~737*737mm

Cleaning method

Enhanced vacuum adsorption function

Dry, wet, vacuum three modes

cleaning back and forth

Image:

image field(FOV)

10*8mm

Datum point type

Standard shape reference point

pad

hole

Camera system

Vision system for top/bottom imaging

analog camera

Geometry match positioning

Performance:

System alignment accuracy and repeatability

±12.5um@6σ,CPK≥2.0

Actual solder paste placement repeatability

±18um@6σ,CPK≥2.0

Repeatability of actual solder paste printing position based on third-party test system (CTQ, Germany) verification

printing cycle

<7.5 sec (excluding printing and cleaning time)

Equipment:

Power requirements

AC:220±10%,50/60HZ,2.5KW

Compressed Air Requirements

4~6 Kgf/cm2

Air consumption

around 5L/min

Working temperature

-20℃~+45℃

Working environment humidity

30%~60%

Machine height (remove tri-color light)

1530(H)mm

Machine length

1156(L)mm

Machine width

1400(W)mm

Machine weight

Approx: 1000Kg

GKG G9 Fully Automatic SMT Stencil Printer Details:

G9 automatic vision printing machine is a new product for high-end SMT applications, which can perfectly meet the process requirements of 03015, 0.25pich and other fine pitch, high precision and high speed.

G9 is high accuracy and high stability of the fully automatic printing machine vision,GKG followed in SMT industry is the development trend of production of a new generation of fully automatic printing machine with the international leading technology synchronous vision, visual processing of high resolution, high precision of the transmission system, suspension adaptive scraper.

Standard function

1. CCD digital camera system

Brand-new optical path system--uniform ring light and high-brightness coaxial light, together with the brightness function that can be adjusted steplessly, makes all types of Mark points (including uneven Mark points) can be well identified and suitable for plating. Tin, copper-plated, gold-plated, tin-sprayed, FPC and other types of PCBs with different colors.

2. High-precision PCB thickness adjustment jacking platform

The structure is compact and reliable, the lifting is stable, and the PIN needle height is automatically adjusted by software, which can accurately adjust the position and height of PCB boards with different thicknesses.

3. Guide rail positioning system

International utility model invention patent. Detachable, programmable flexible side clamp device, for soft board, warped PCB, a unique top flattening, through software programming, can be automatically stretched, does not affect the tin thickness.

4. Brand new scraper structure design

Through the new scraper structure of the slide rail and the cylinder, the operation stability is improved and the service life is prolonged.

5. High-speed stencil cleaning

The drip-type cleaning structure can effectively prevent the cleaning caused by local lack of solvent caused by the blocking of the solvent pipe.

6. New multi-function interface

Simple and clear, easy to operate. Real-time temperature remote control function.

Option function

1. Steel mesh inspection function

By compensating the light source above the stencil, and using CCD to check the mesh of the stencil in real time, so as to quickly detect and judge whether the stencil is blocked after cleaning, and perform automatic cleaning, which is a 2D inspection of the PCB board. Replenish.

2. Automatic dispensing system

According to different printing process requirements, after printing, the PCB board can be accurately dispensed, tinned, drawn, filled and other functions; at the same time, the dispensing head is also equipped with a heating function, which can be used at a lower ambient temperature. When heating, the glue is heated to improve the fluidity of the glue.

3. Bottle type automatic tinning and solder paste detection function

Automatically add solder paste at regular and fixed points to ensure the quality of the solder paste and the amount of solder paste in the stencil. So as to ensure the printing quality of customers and improve productivity.

Through the sensor, the amount of solder paste on the stencil is managed, and the quality is stable and long-term continuous printing is possible. Productivity is improved.

4. SPI connection

It is connected with SPI to form a closed-loop system. When the feedback information of poor SPI printing is received, the machine will automatically adjust according to the SPI feedback offset. The XY direction offset can be automatically adjusted in 3PCS, and the stencil can be cleaned to improve printing. Quality and production efficiency constitute a complete printing feedback system.

5. Leading the compatibility of Industry 4.0

6. Through the automatic upload or output of machine status and parameters, it can provide a strong guarantee for the customer's Industry 4.0 intelligent production. It can realize seamless connection with the customer's MES system, and realize the self-distribution of engineering personnel at all levels according to on-site management. permissions.

GKG G9 Fully Automatic SMT Stencil Printer Picture Show:

Exhibition:

SMT LINE: