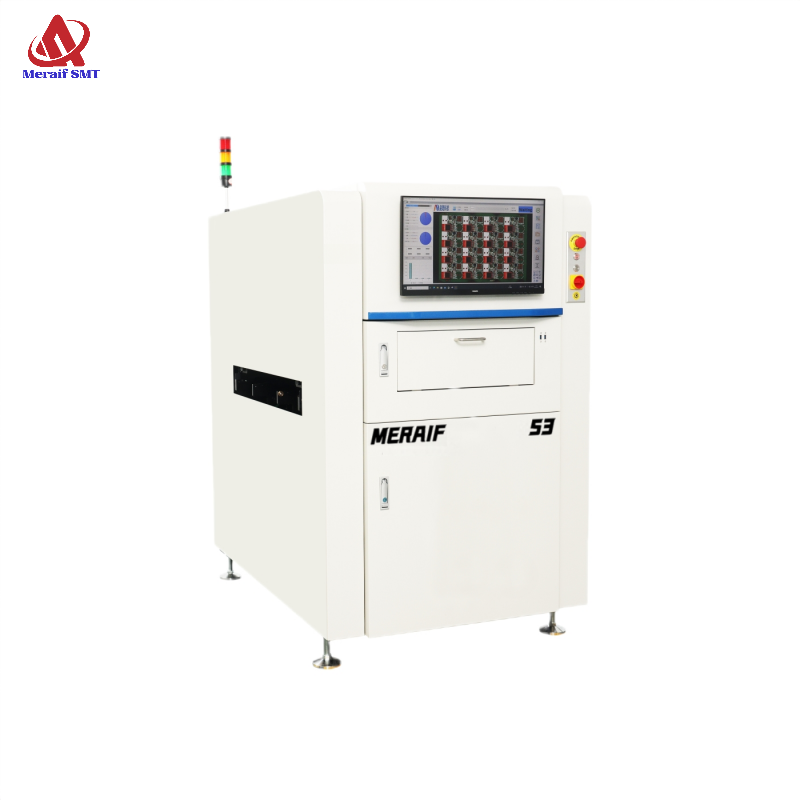

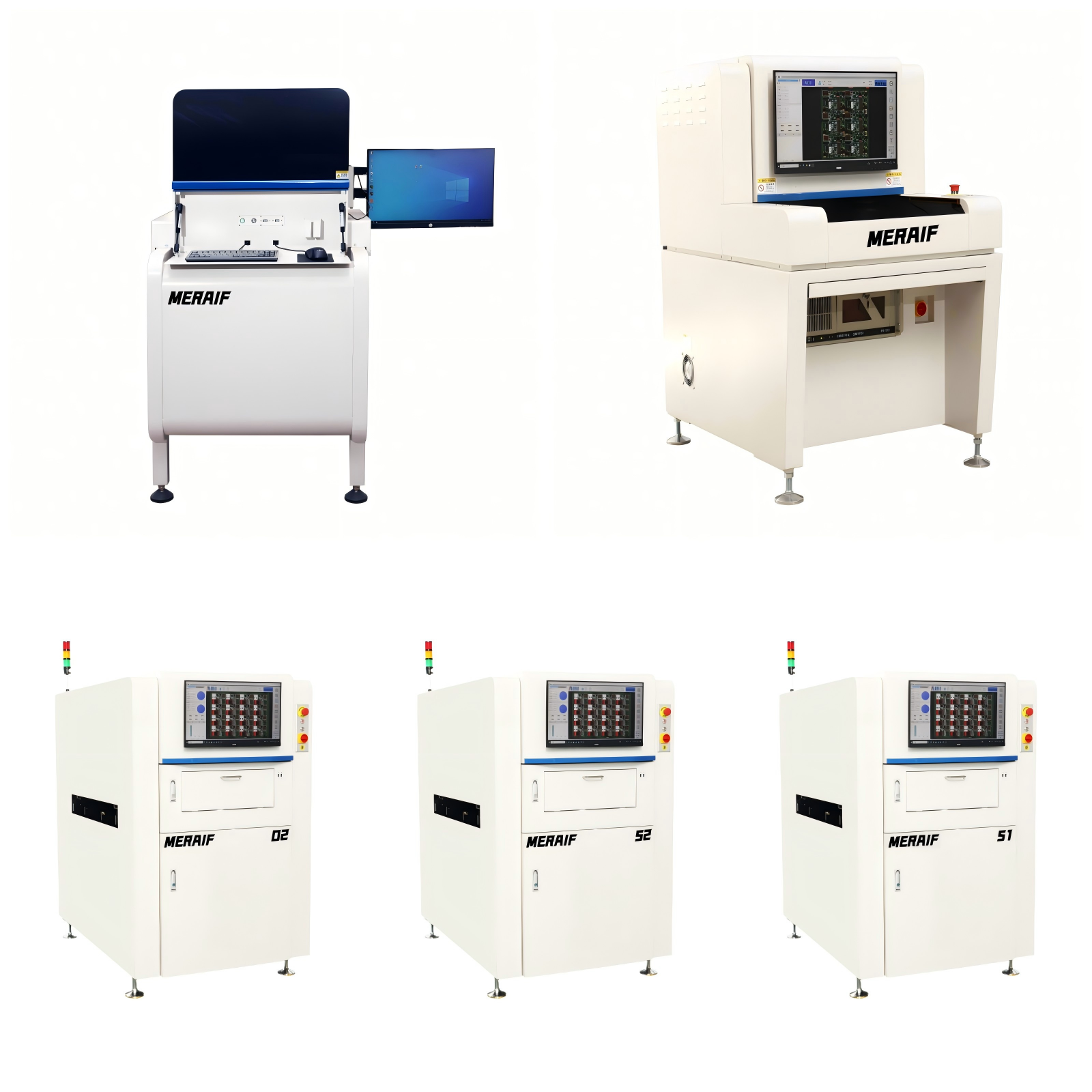

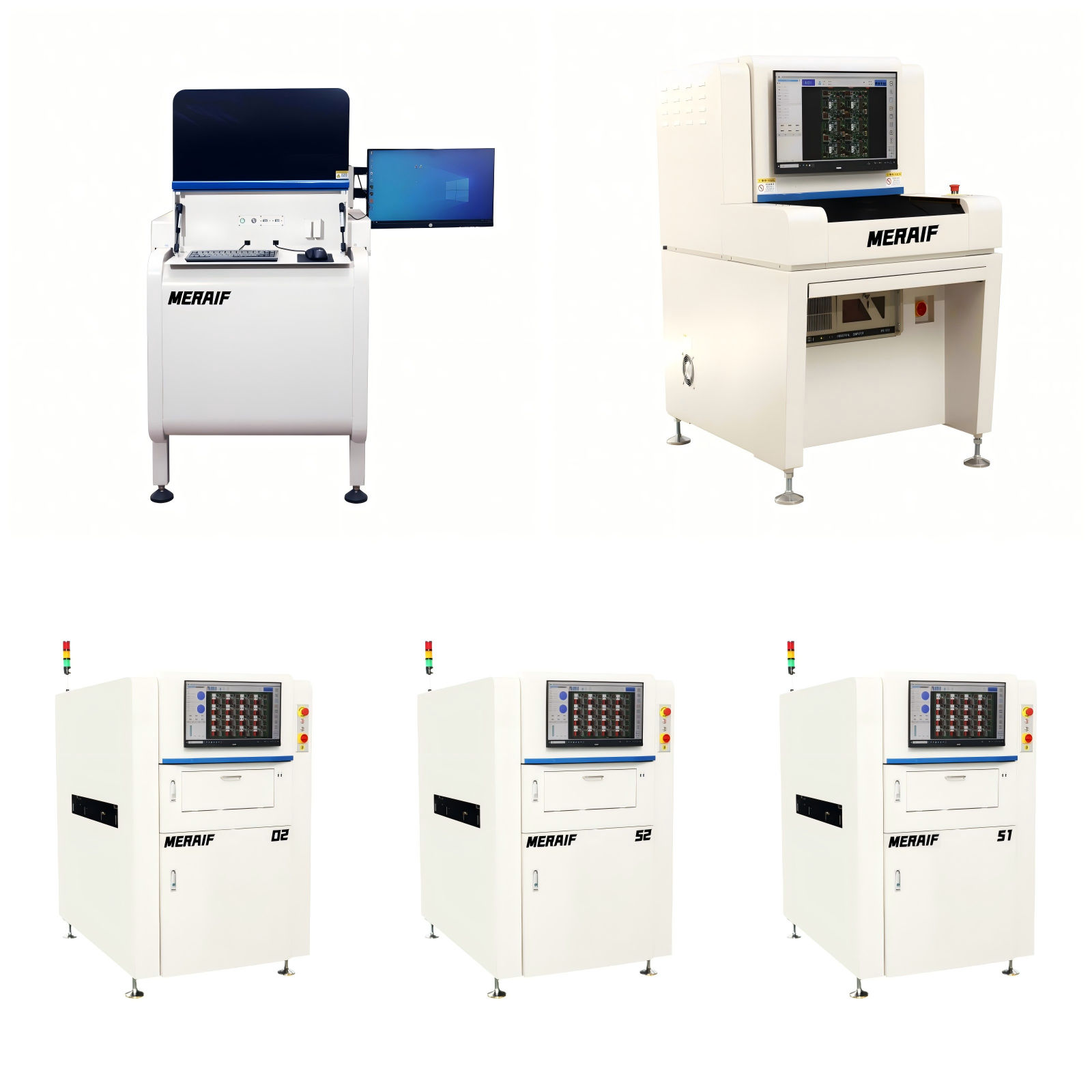

MERAIF D3 3D AOI SMT Machine AOI Inspection Automated Optical Inspection SMT 3D AOI SMT AOI Machine AOI Machine In SMT Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

MERAIF D3 3D AOI Technical Parameters :

| Model | D3 |

| PCB size | 50×50mm-510×400mm |

| Thickness | 0.5mm-6mm |

| Component height | Top:60mm,bottom:60mm |

| Process side | 5mm |

| Camera | L&U 12MP color tace array high-speed industriat camera |

| Illuminant | L&U RGB+W four-color ring LED light source |

| Resolution | 10um/15um |

| FOV | 10um@40*30mm(Optional apolegamy)/15um@60*45mm |

| Component detection | Leak,reverse,offset,damage,multiple,foreign body,defacing of patch elements,etc |

| Welding tin detection | More tin,lesstin,tin,not out of the foot,empty welding,virtual welding /tin hole,etc |

| Surface element detection | Missing parts,muliple pieces,ftip,reverse,fse,damage,skew,foreign body,stain,etc |

| Barcode identification | 1D/QR code identification/character recognition,etc |

| Mixed board test | Mixed board production,support program automatically call |

| Algorithm | Deep neural network algorithm,image contrast,color contrast,contour recognition,etc |

| Speed | 0.25sec/FOV |

| Function | Remote control,remote assistance,gerber file import,and custom model training |

| Communication mode | Standard SMEMA interface |

| Presentation of data | Automatically generate the statistical analysis SPC |

| Host computer | Industrial control computer |

| Indicator | 24-inch FHD indicator display |

| Gear | High-precision wire rod+servo motor |

| Track adjustment | Manual/automatic |

| Case size and weight | 1010×1370×1611 mm/Approx.880KG |

| Power | AC 220V,power rating 2.5KVA |

| Air supply | 0.4-0.6Mpa |

| Ambient temperature | Temperature: 10-45℃, humidity: 30-85%RH |

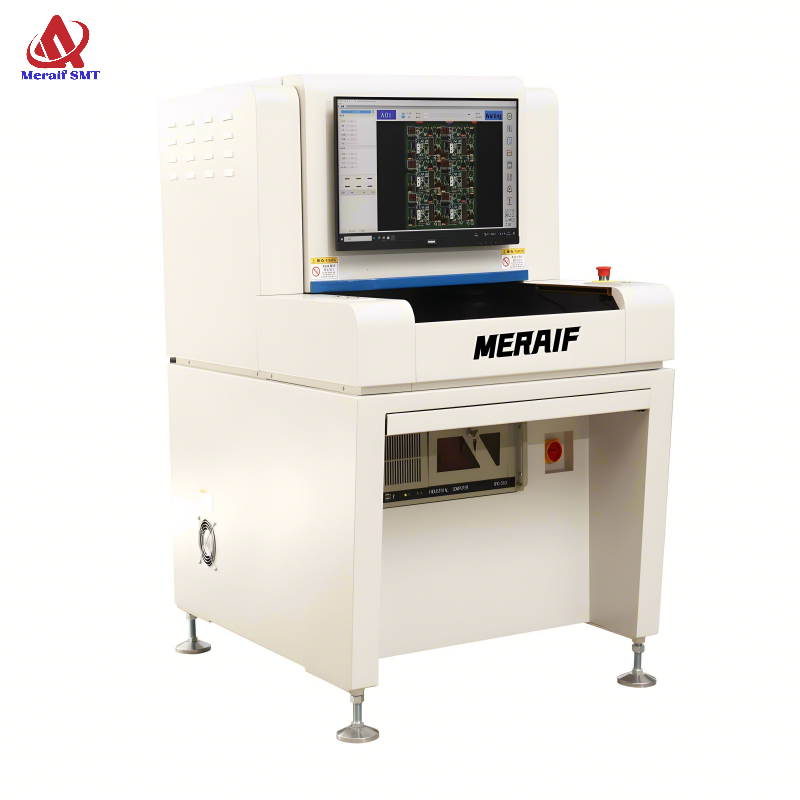

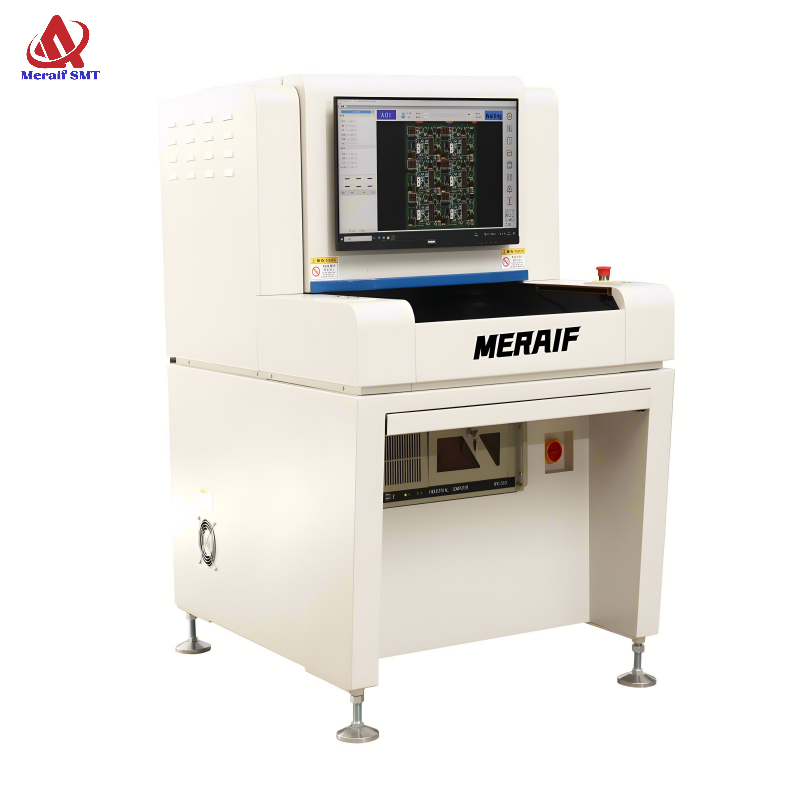

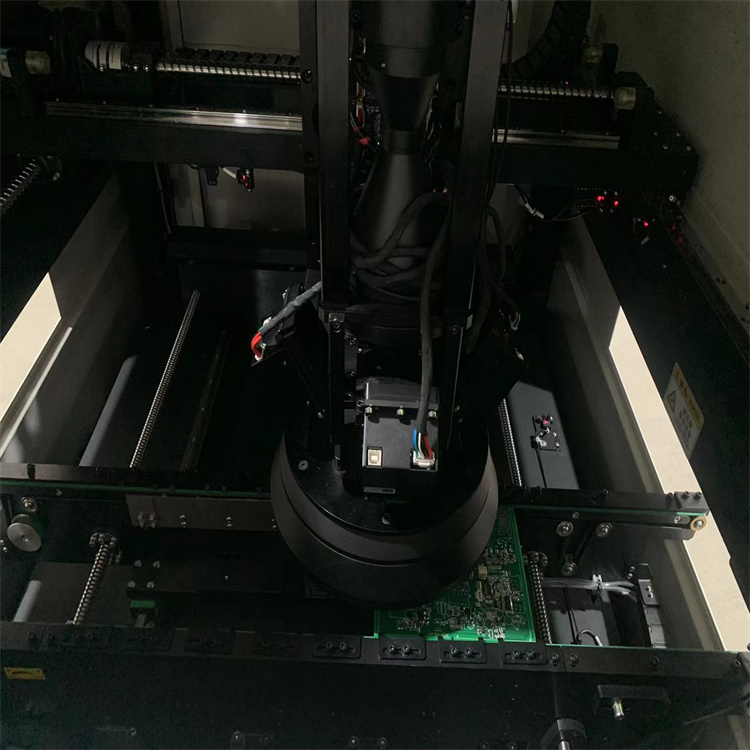

MERAIF D3 3D AOI Details:

Downward-illuminated AOI-D3

Online PCBA solder optical inspection equipment

Detect defects such as missing, reversed and soldering, capture board images in real time through high-precision color industrial cameras, use convolutional neural network algorithms to process images, and intelligently determine component defects.

Features

- Al intelligent algorithm, one-click search andpositioning, programming is fast and simple

- Online programming:the equipment parameters can beoptimized and adjusted

- Data traceability, support for SPC alarm

- Flexible coordination with the production line, to adaptto a variety of production scenarios

MERAIF D3 3D AOI Picture Show:

EXHIBITION:

SMT LINE: