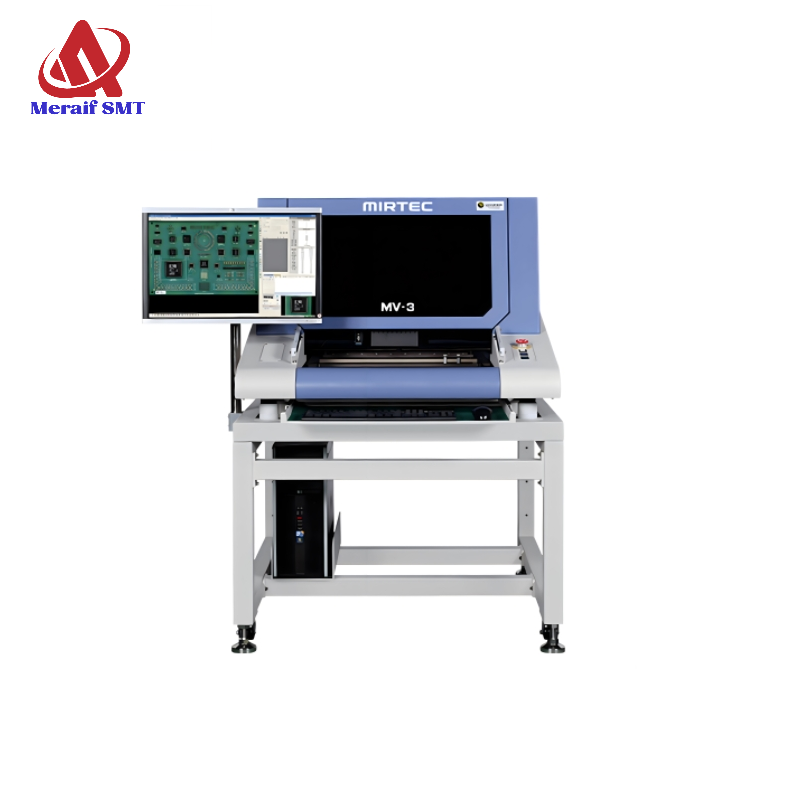

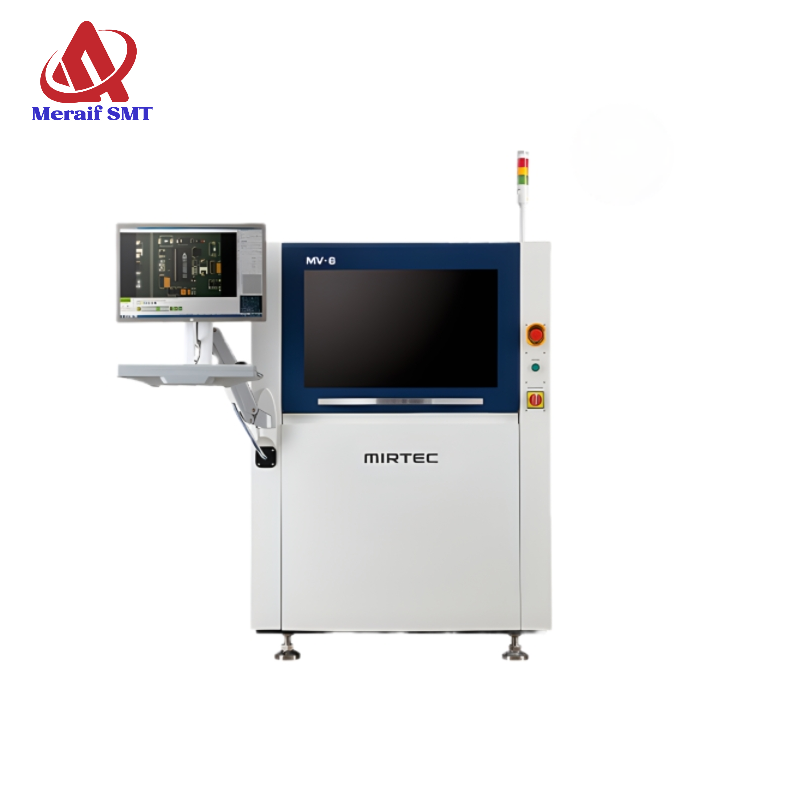

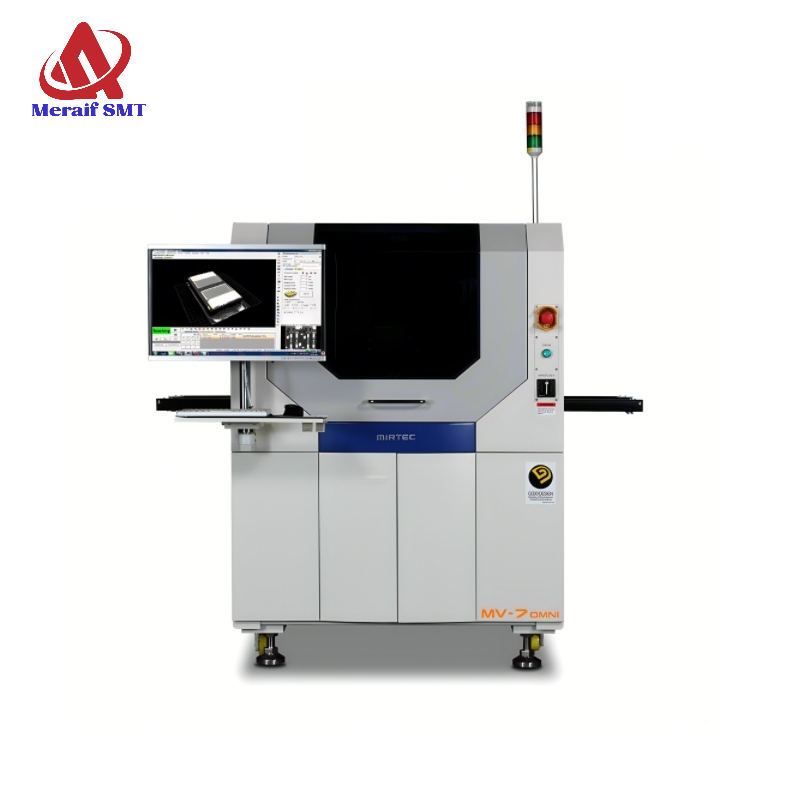

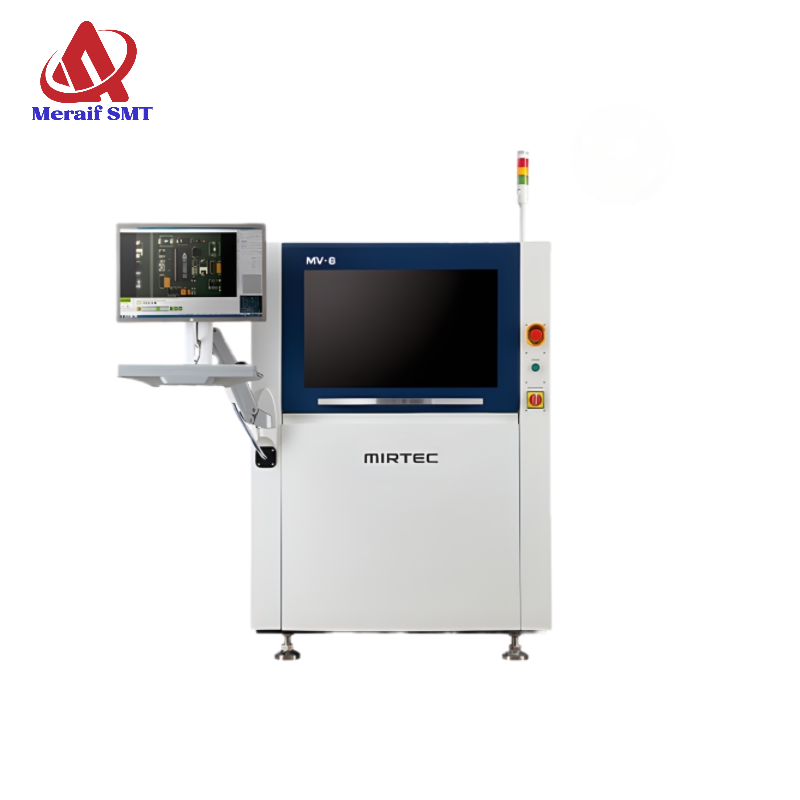

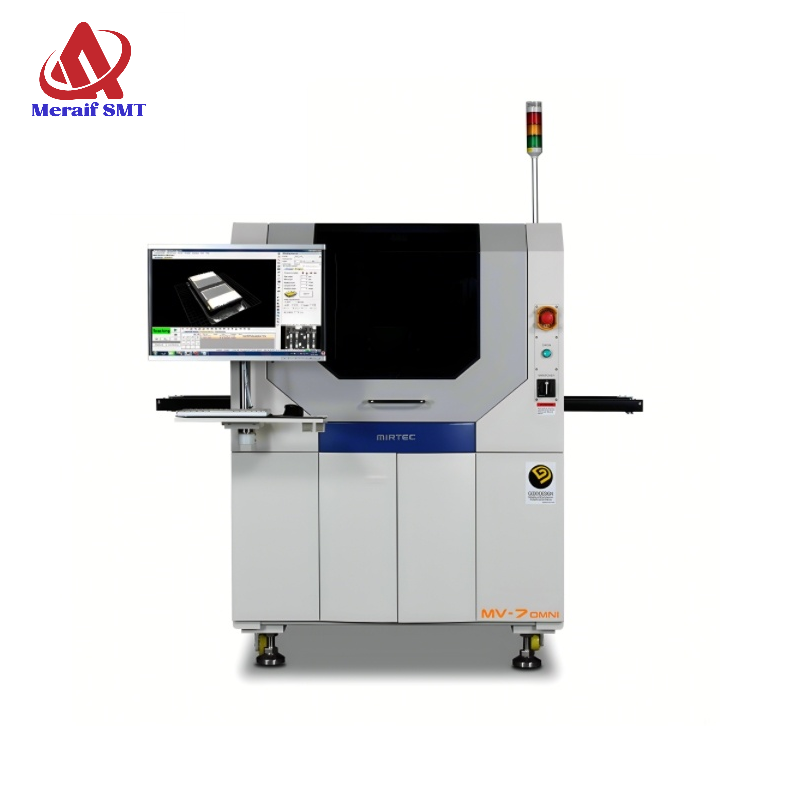

MIRTEC MV-9 3D AOI SMT LINE AOI 2D Automated Optical Inspection System AOI Equipment AOI Machine For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

MIRTEC MV-9 3D AOI SMT LINE AOI Technical Parameters:

MODEL

MV-9

PCB Inspection Area

MV-9

50mmx50mmto510mmx460mm(2.0"×2.0"to20.1"x18.1")

PCB Indexing Mode:50mmx50mmto1,020mm×460mm(2.0"×2.0"to40.16"x18.1")

MV-9U

60mmx60mmto660mmx610mm(2.36"×2.36"to26.0"x24.1")

PCB Indexing Mode:60mmx60mmto1,320mmx610mm(2.36"×2.36"to51.97"×24.1")

MV-9DL OMNI(Dual Lane)

Vision System (FOV Size)

15MP CoaXPress:(3,904×3,904 @120 fps)

Option 1

Pixel Resolution:15um

58.56mmx58.56mm(2.31”×2.31”)

Option 2

Pixel Resolution:10um

39.04mmx39.04mm(1.54”x1.54”)

25MP CoaXPress:(5,120×5,120 @72 fps)

Option 1

Pixel Resolution:7.7um

39.42mmx39.42mm(1.55”X1.55”)

OMNI-VISION Inspection Technology

3D Inspection Technology

Digital Tri-Frequency Moiré Technology-12 Projection Blue DLP

2D Inspection Technology

15MP/25MP CoaXPress Camera System

Maximum 3D Inspection Height

25mm @±3um

2D Inspection Item

Missing Component,Wrong Component,Mis-Alignment,Skewed Component,Polarity,Tombstone,Solder Bridge,Flipped Device,Solder Ball,Etc

3D Inspection Item

Component Height,Position,Lifted Package,Lifted Lead,Solder Fillet,Excessive Solder,Insufficient Solder,Solder Bridge,Open Solder,Etc

Additional Specifications

Lens Configuration

Precision Telecentric Compound Lens Design

Lighting System

Eight Phase Color Lighting

SIDE-VIEWERO Camera System

PCB Surface Clearance

Top-Side Clearance:45mm /Bottom-Side Clearance:50mm

PCB Edge Clearance

Top-Edge Clearance:3mm /Bottom-Edge Clearance:3.5mm

Maximum PCB Warpage

±2mm

Maximum PCB Weight

Standard:4Kg(8.82 Lbs.)

PCB Thickness Range

Standard:0.5mm-3mm /Optional:0.5mm-5mm

Minimum Component Inspection

0402Chip (mm)/01005Chip (in)/0.3Pitch (mm)

Robot Positioning System

Precision Linear Drive System,Resolution:0.2 um /Repeatability:±2 um

Power Requirements

Single Phase 200~240V 50~60Hz;1.1 KW,Breaker Capacity:25 Amp

Air Requirements

5Kgf /cm²(0.5 Mpa);(71 PSI)

Machine Dimensions and Weight

MV-9

1,250mmLx1,500mmDx1,600mmH(49.21"x59.06"x62.99")/1,200Kg(2,645.55lbs.)

MV-9U

1,400mmLx1,650mmDx1,600mmH(55.12"x64.96"x62.99")/1,500Kg(3,306.93lbs.)

MV-9DL

1,250mmLx1,500mmDx1,600mmH(49.21"x59.06"x62.99")/1,400Kg(3,086.47lbs.)

MIRTEC MV-9 3D AOI SMT LINE AOI Details:

The MV-9 series is the first In-Line 2D/3D AOI which utilizes a 15 Mega Camera, 4 way Multi-Frequency 3D Moiré technology and a linear motor system.With simultaneous 2D/3D tests in one head highest productivity is achieved and falls calls are avoided.

Advantages of the 2D/3D inspection

• 3D OMNI-Vision® System

• Achieve ZERO false call by 2D/3D concurrent inspection

• Complete 3D measurement (height, area, tilt, lift, etc.)

• Complete soldering inspection by 6 Phase colour lighting system

• Detect side defects with 10 Mega Side Viewer®

• Non-distortion during image magnification

• Applied 1µm high precision linear motor

The 2D inspection happens with the approved advanced 15 Mega Pixel digital colour camera technology and high resolution telecentric lens. This technology provides the ultimate inspection performance and speed. The optional Side Viewer® Camera System provides enhanced inspection capability through the addition offour Ten Mega Pixel Side View Digital Colour Cameras.

Inspection Performance 2D

• High resolution digital 15 Megapixel colour camera and telecentric lens

• Fast PCB inspection: up to 83 cm²/sec

• MIRTEC’s innovative Quad Angle Lighting System for an enhanced solder joint and solder bridge inspection capability

• The optional 10 MP side Viewer® Camera System for an enhanced detection of complex components.

• Three stage conveyor system with automatic board support and PCB clamping mechanism is designed for

maximum throughput of the line

• Precision motion control systems provide absolute reproducibility and repeatability.

• Powerful OCR Engine provides advanced part marking inspection

By changing the magnification of the Precision Telecentric Lens the resolution of optics system may be scaled from 20 microns/pixel with an incredibly large FOV of (77.7mm x 77.7mm) desired for extremely high speed manufacturing; down to 10 microns/pixel with an FOV of approximately (38.8mm x 38.8mm) which is suitable for high end micro-electronics manufacturing.

MIRTEC’s revolutionary 3D Multi Frequency Quad Moiré Technology, provides true 3D inspection of SMT devices on finished PCB assemblies using a total of four (4) Moiré Inspection Probes. This proprietary system yields precise height measurement used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured the new MIRTEC MV-7 machines will also feature four 10 Mega Pixel Side-View Cameras in addition to the 15 Mega Pixel Top-Down Camera.

MIRTEC MV-9 3D AOI SMT LINE AOI Picture Show:

EXHIBITION:

SMT LINE:

EXHIBITION:

SMT LINE: