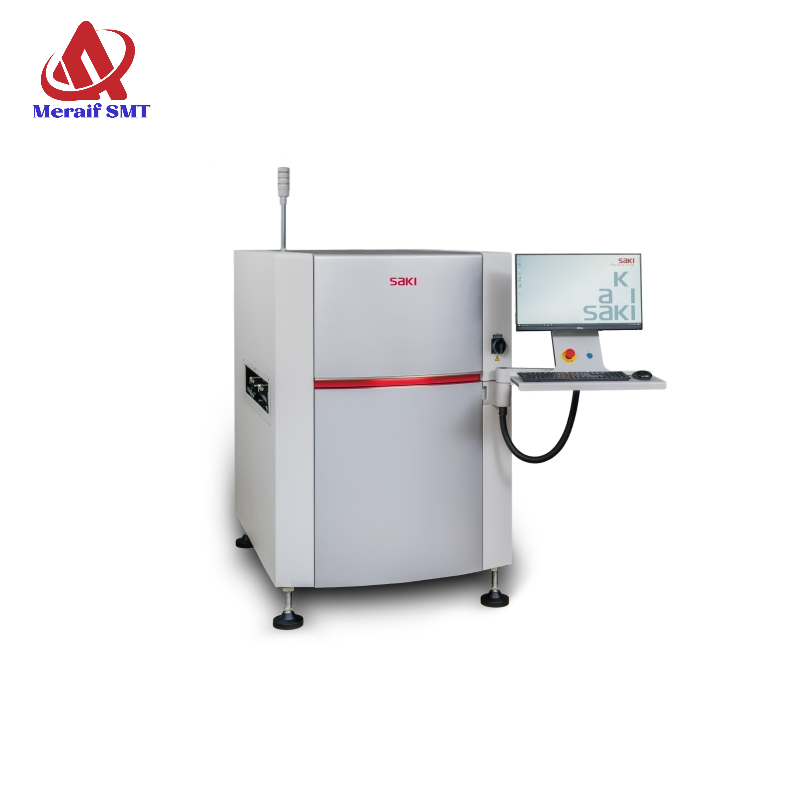

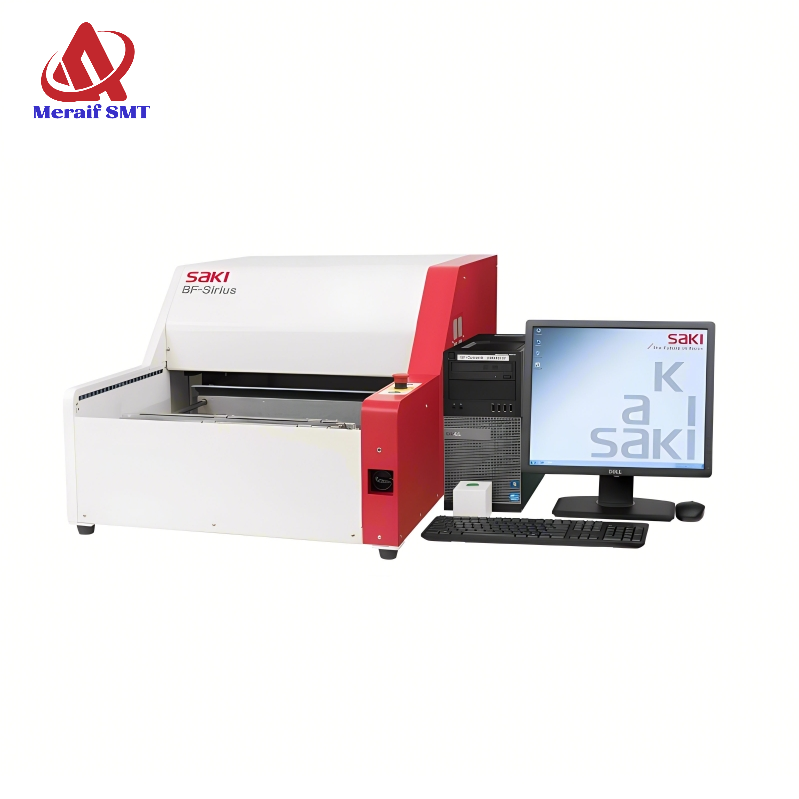

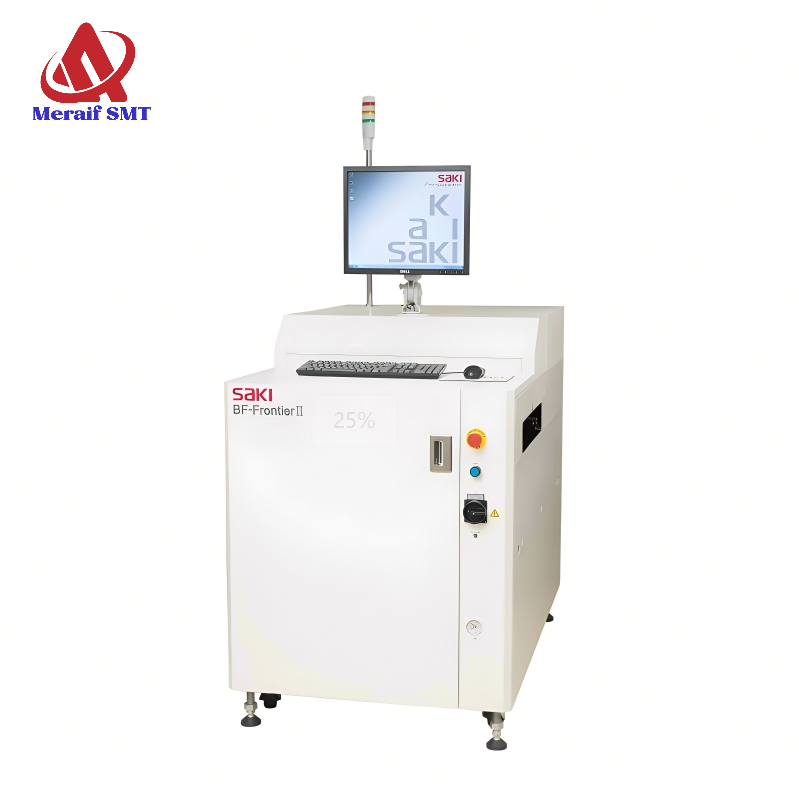

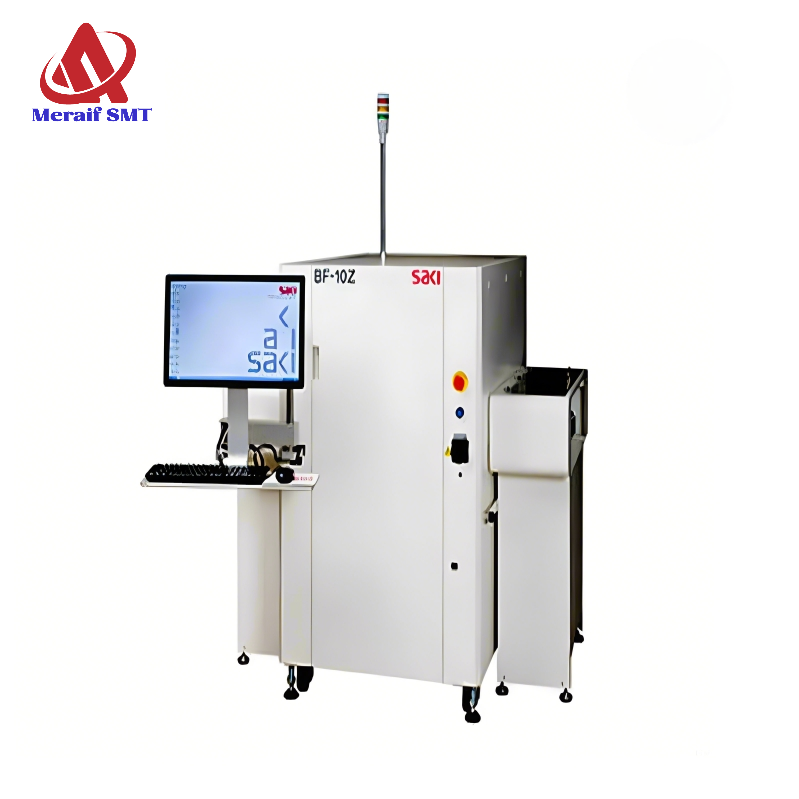

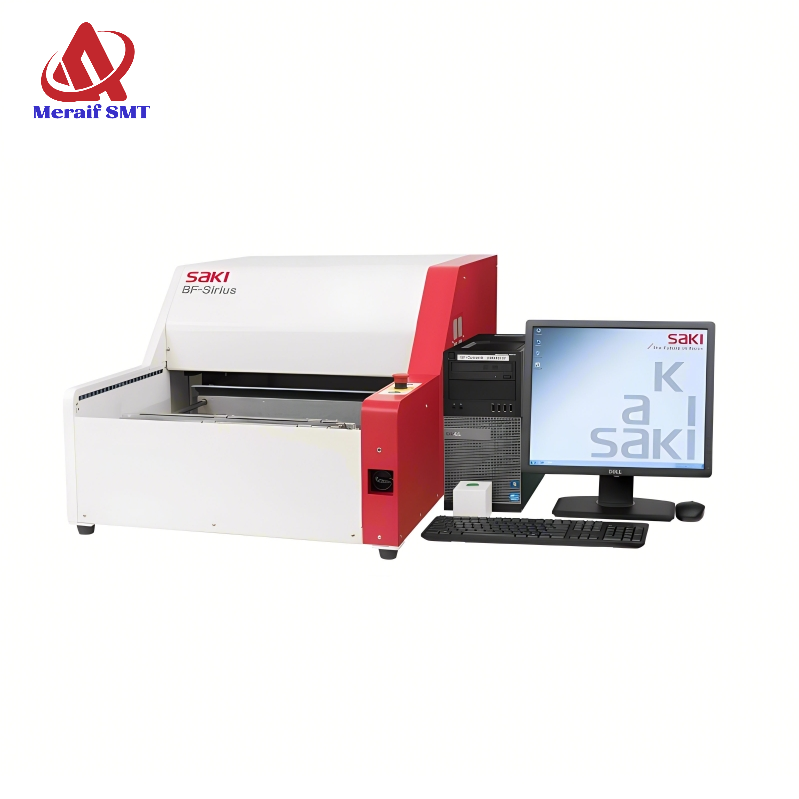

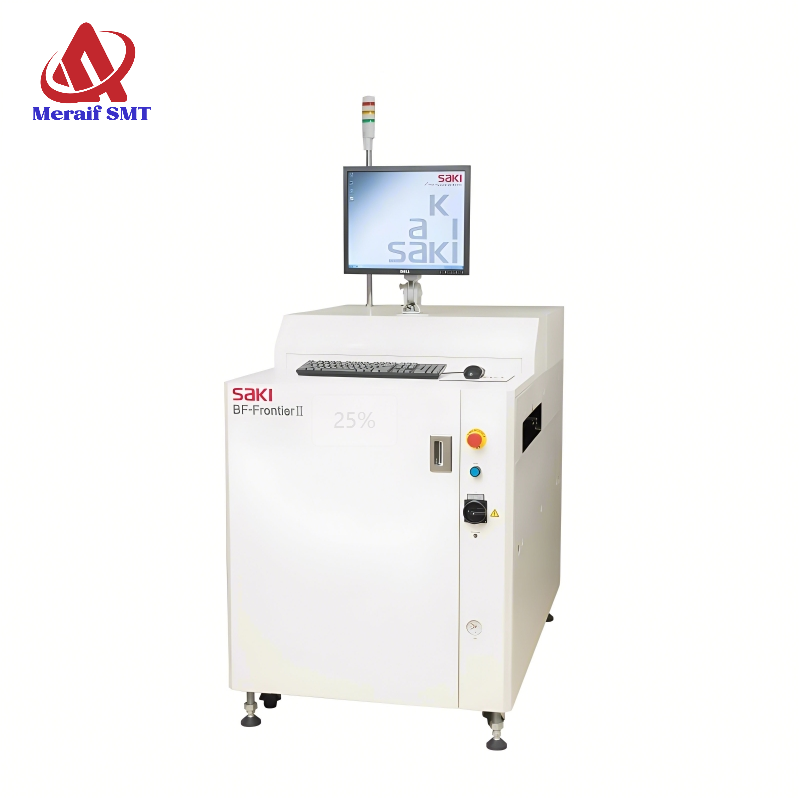

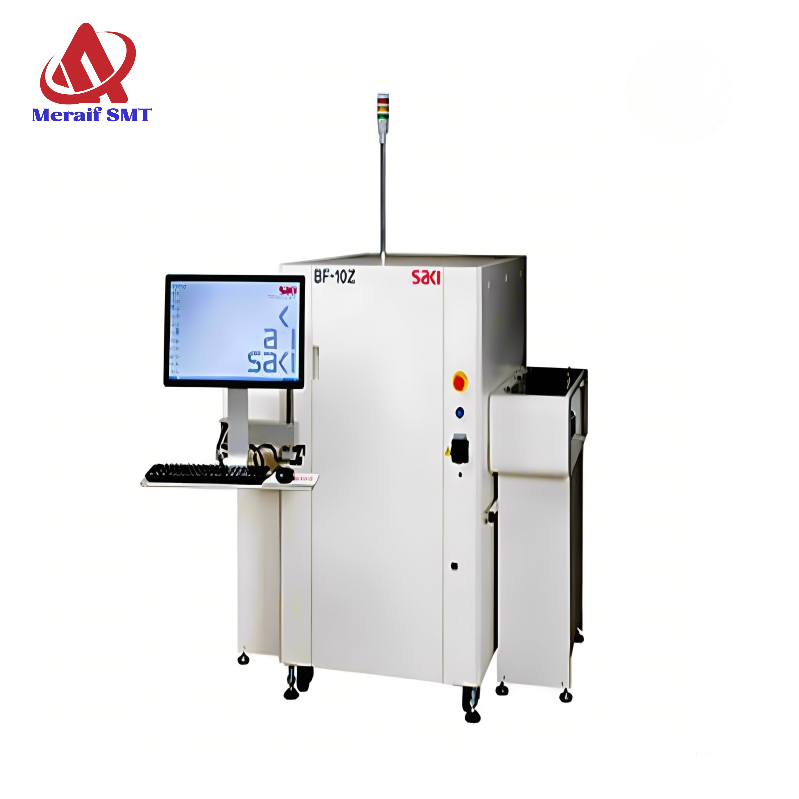

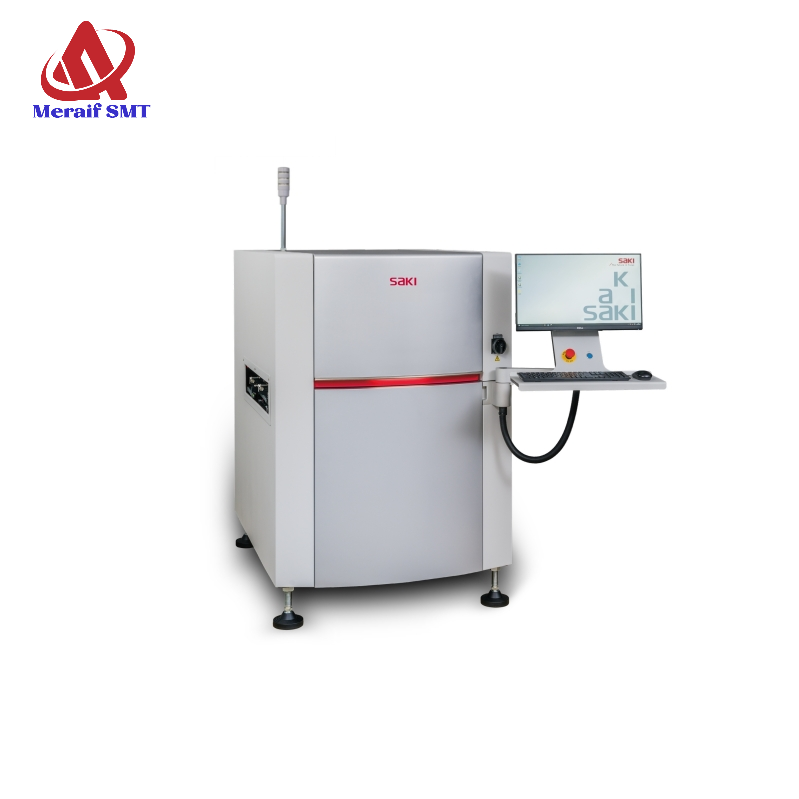

SAKI 3Di-Series 3D AOI SMT AOI 3D Automated Optical Inspection System AOI Equipment AOI Machine For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

SAKI 3Di-Series 3D AOI SMT AOI Technical Parameters:

SAKI 3Di-Series 3D AOI SMT AOI Details:

Market

Asia

Global

Dimensions

Model Name

3Di-MS2

3Di-MD2

3Di-LS2

3Di-LD2

3Di-ZS2

Weight

850kg,1873.93Ib

900kg,1984.16lb

Electric Power

Single Phase~200-240V+/-10%,50/60Hz

Air Requirement

0.5MPa,5L/min(ANR)

ー

ー

ー

【7μm camera head】

【7μm camera head】

【12/18μm camera head】

【12/18μm camera head】

PCB Clearance

1: Advanced Hardware Features

Proprietary Hardware provides accurate measurements Saki's machines are built with hardware that's made to last.A closed-loop, dual servo motor drive system, high-resolution linear scale, and rigid gantry structure provide unsurpassed accuracy and repeatability for absolute measurements.An optimized conveyor system, driven by step motors, enables fast PCBA loading and unloading.

Self-diagnostic System

Saki's predictive and preventive maintenance management system assures stable machine conditions and repeatable, consistent performance. Every key component is monitored along with system conditions, and a detailed diagnostic log is recorded. The optimized preventive maintenance plan reduces maintenance time, machine down-time, manpower, and costs.

Optical Unit

Four, multi-frequency digital projectors provide accurate 3D measurements for high-quality images.Three camera resolution levels – 7µm, 12µm, and 18µm – are available to match application requirements.Saki's CoaXPress interface in the overhead camera captures images 1.7 times faster than previous models.Enhanced 2D and 3D calibration uses multiple calibration height targets for positive and negative heights to guarantee height measurement accuracy.

Side Cameras*

A quad side camera system ensures inspection of the entire board, including dead angles and areas missed by overhead cameras. *factory-installed option

2: Advanced Software Features

Programming

Special BF2 software has a common user-interface for Saki's 3D SPI, AOI, and AXI systems.

The software saves a full 3D image of the whole PCBA, so the operator can create inspection data without using the physical board.

Saki's Easy Programming Function was developed on the concepts of Board less, Skill less, and Stress less. Detailed component libraries can be automatically created using Saki's database and BOM data.

Inspection Data per IPC Standards

Default thresholds of inspection data conform to IPC standards.

Measurement inspection and tuning function

Offline Debugging: Operator can edit inspection data to check previous Good/NG images, or real-time defect images, offline without any production interruptions.

Warpage Adjustment: Warpage is compensated automatically. An accurate height map is made of the entire PCBA surface, enabling the Extra Component Detection function to detect foreign material.

Fujiyama (Through-hole device Solder Inspection):

The Fujiyama algorithmprovides complete through-hole joint inspection in a single step.It simultaneously inspects for copper exposure, pin detection, pin-holes, solder fillets, and bridges.

Inspection Data Verification

History Management System: The History Management System records the detailed data modification system in detail (who, what, when, where, why, and how).

"Golden-Silver Board Function" Maintains inspection accuracy by checking machine status and inspection conditions before starting auto operation.

3: Applied Technology

Machine-to-Machine (M2M) Solution

1.Feed-back from SPI to Screen Printer. Feeds back misalignment data and prevents print errors by automatically alerting the user when the stencil needs cleaning.

2.Feed-forward from SPI to Pick-and-Place machine. Measures the degree the printing position shifts to correct placement positioning. A NG board skip function improves efficiency, quality, and cost.

3.Feed-back from AOI to Pick-and-Place machine. Feeds backplacement position and location data from AOI to pick-and-place and feeds forward data from SPI to improve quality and efficiency.

4.Automated line control function. Automates control of the assembly line to reduce rework and waste and increase throughput.

* For items 1-4 above, Saki partners with the leading PCB equipment manufacturers. Ask us which products we connect with.

Options

BF2-Editor

Create data and debug the process offline.

BF2-Monitor (Offline verification terminal)

RMS (Remote Management System). Remotely control multiple BF2-Monitors with a single PC. Reduces assembly-floor personnel. Moreover, the production status of each device can be confirmed.

MPV (Multi Process View). The BF2-Monitor shows the results of all inspection processes (SPI, pre-reflow, and post reflow) on one screen in real time for operator review, simplifying the verification process and making it less subject to error. It is also useful for analyzing the cause of a defective board.

3Di Series Product Specifications

Dual-lane system can inspect 2 different PCBAs simultaneously

SAKI 3Di-Series 3D AOI SMT AOI Picture Show:

EXHIBITION:

SMT LINE:

EXHIBITION:

SMT LINE: