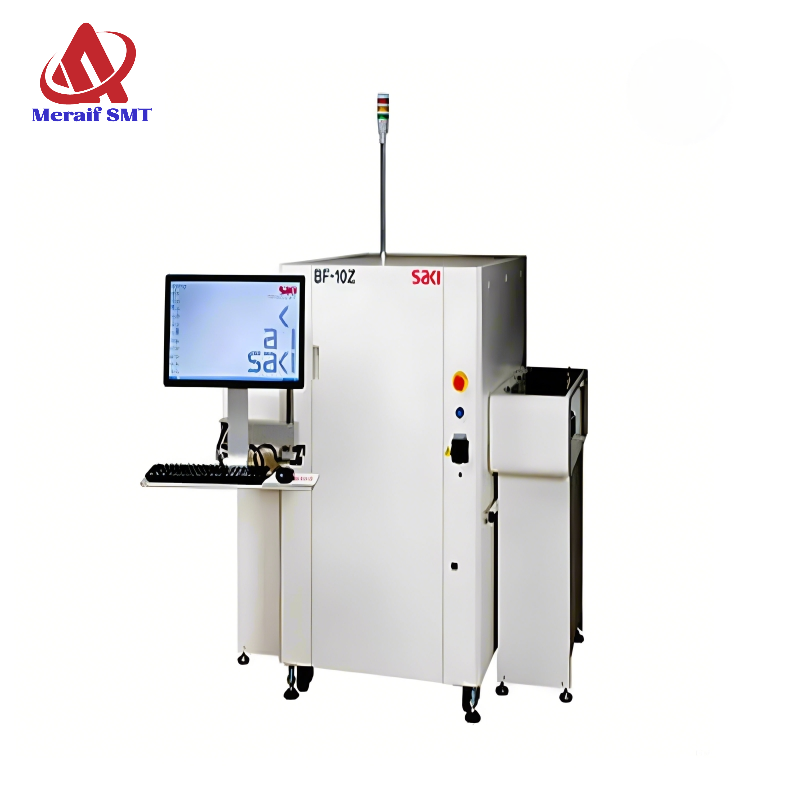

SAKI 3Xi M200 3D AOI SMT AOI 3D Automated Optical Inspection System AOI Equipment AOI Machine For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

SAKI 3Xi M200 3D AOI SMT LINE AOI Technical Parameters:

Model

3Xi-M200

Resolution

51μm-104μm

Loading size

Loading Thickness

Warpage

2mm(0.08in.) or less

Loading Clearance

Top:68mm(2.68in.)Bottom:40mm(1.57in.)

Inspection Categories

IGBT Module solder inspection,Presence/Absence,Misalignment,Tombstone,Bridge,Foreign material,Absence of solder,Insufficient solder,Dryjoint,Lifted bump,Lifted lead,Lifted chip,Fillet defect,and Void

Detector

Saki Detector V2

X-ray Source Type

Closed X-ray tube 180kV

X-ray leakage

0.5μSv/h or less

Transfer Conveyor Method

Flat belt transfer

Transfer Conveyor Height

880-920mm(34.65-36.22in.)

Transfer Conveyor Width Adjustment

Auto Width Adjustment

PC Specification OS

Windows10 loT Enterprise 2019 EMB 64bit(Microsoft)

Three-phase~200V+/-10%,50/60Hz 4.2 kVA With Cable 5m*3

Air Requirement

0.5 MPa @≥20L/min(ANR)

Usage Environment

15℃(59F)-30℃(86F)/15-80%RH (Non-condensing)

Noise Level

70 dB(A)or less

Dimensions

1400 Wx2165 Dx1862 H mm(55.12 Wx85.24 Dx73.31 H in.)

Weight

Approx.5200 Kg(11464.04 lbs)

SAKI 3Xi M200 3D AOI SMT LINE AOI Details:

The new 3Xi-M200 AXI is built with highly rigid and stable hardware required for inspection accuracy, yet it is 20% lighter, with a 25% smaller footprint and an imaging speed that is increased by 30% over its predecessor.The new AXI system joins Saki's recently introduced 3Xi-M110 3D-CT AXI system for printed circuit board assemblies (PCBA) as part of its lineup of compact, lightweight, ultra-high-speed inline 3D-CT automated AXI systems.IGBT modules are semiconductor devices used in transportation systems such as railways and automobiles for controlling high voltages and large currents. High-accuracy image inspection of these modules is very difficult, even with X-rays, because they are usually sealed with a heat sink that has a thick complex structure with multiple layers of solder hidden in the heat sink. Saki's unique powerful 200keV (kiloelectron volt) high-precision X-ray imaging and precision 3D reconstruction, using Saki's planar computed tomography (PCT), provides clear images by penetrating through the heat sink's multiple layers. This technology makes Saki's IGBT X-ray inspection system the most powerful and capable on the market.

The 3Xi-M200 is equipped with a newly developed detector that enables high-sensitivity imaging while expanding the field of view (FOV) and updated 3D-CT reconstruction processing software. Inspection is optimized by linking the hardware and software together with an automated inspection algorithm that provides a much clearer and more reliable image with less noise.

The X-ray inspection system is 1,400mm wide and weighs just 5,100kg, saving manufacturing floor space and enabling easy installation and improved production-line operation. The platform handles board sizes of 50 x 140mm (W x L) to 360 x 330mm (W x L). For larger 360 x 510mm (W x L) boards, 2-step image capture is available. The machine's cast iron frame maintains the rigidity needed for stable operation.

Extremely high positioning accuracy is achieved by optimizing motor power with a double motor-driven system equipped with a high-precision linear scale manufactured by Magnescale Co Ltd. Saki's original PCT technology algorithm has also been optimized to improve image capture speed by 30%, reducing production-line takt time.

Saki's conventional model BF-X2 AXI system is highly rated for the accurate image quality produced with its unique Planar CT technology, and it's already being employed extensively by major IGBT module suppliers around the world. With the new 3Xi-M200, the company has succeeded in further improving its inspection image accuracy, operational ease-of-use, and effectiveness as an inline system. It's reduced weight and footprint, increased speed, rigid hardware platform, and imaging accuracy provide the high-precision, high-quality, fully automated inspection solution required for IGBT modules.

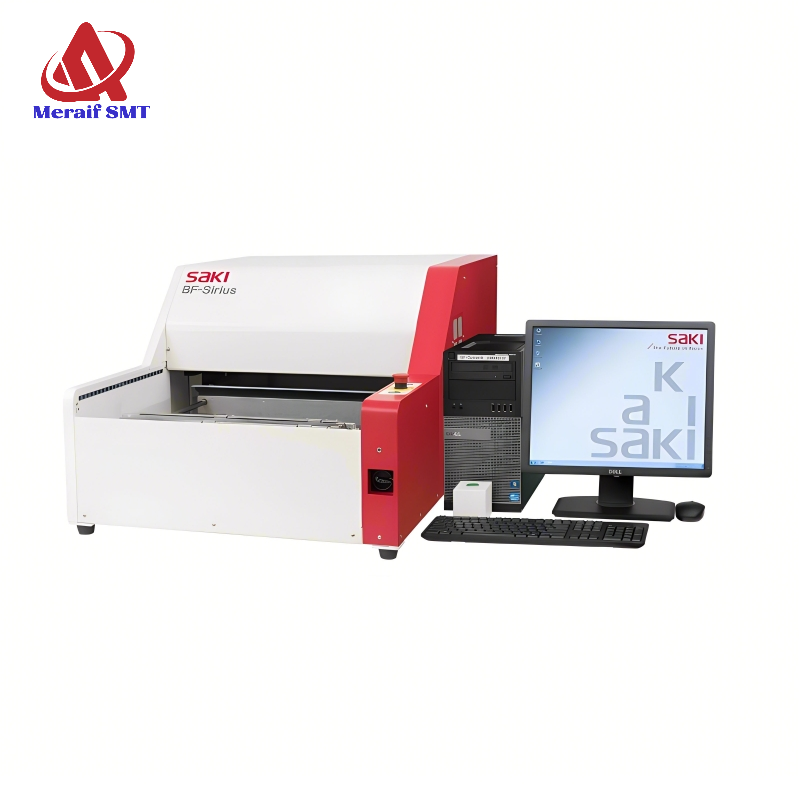

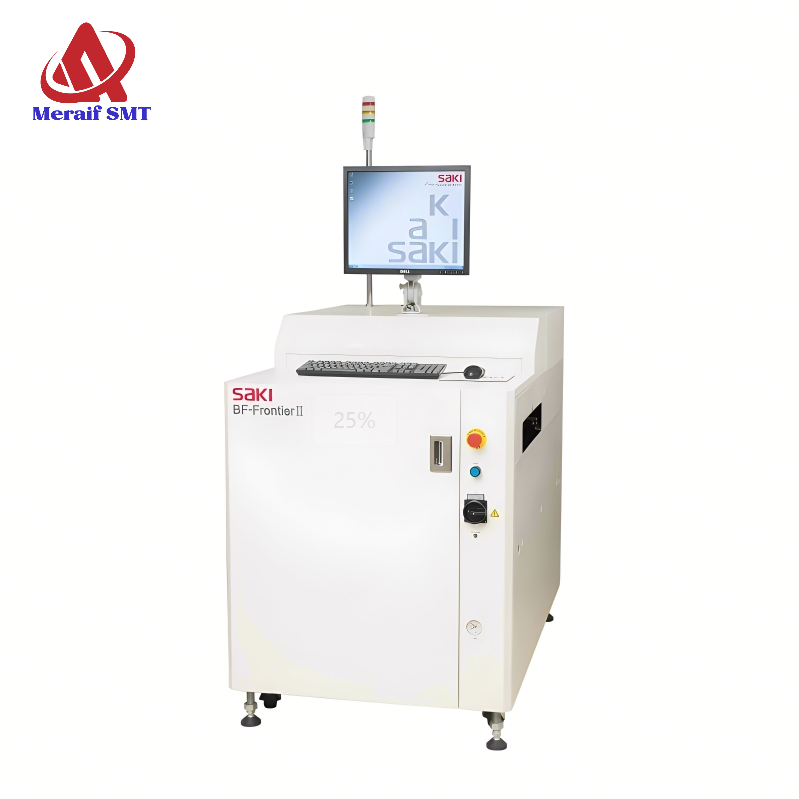

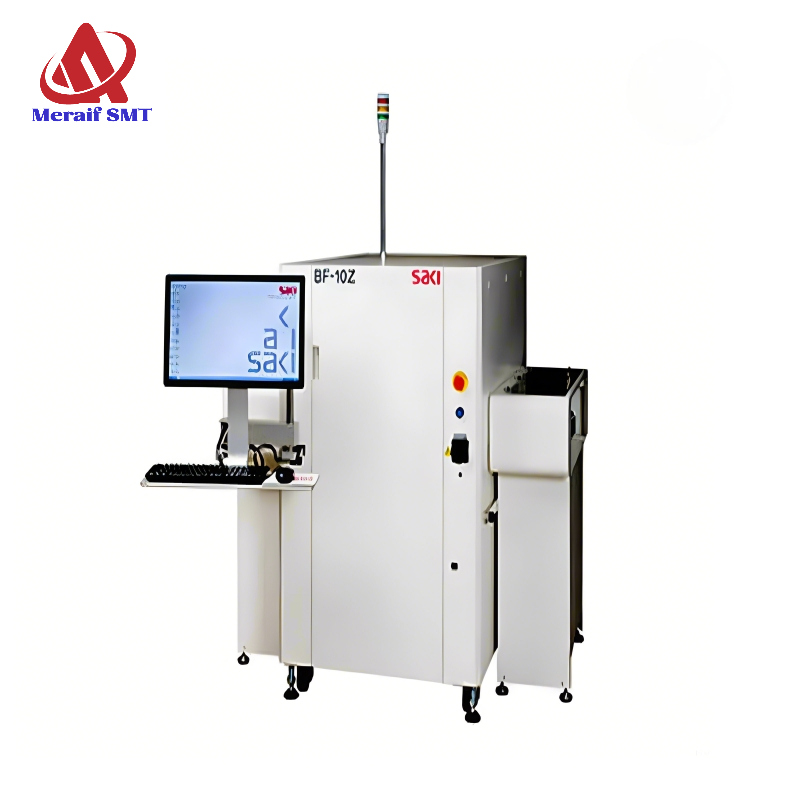

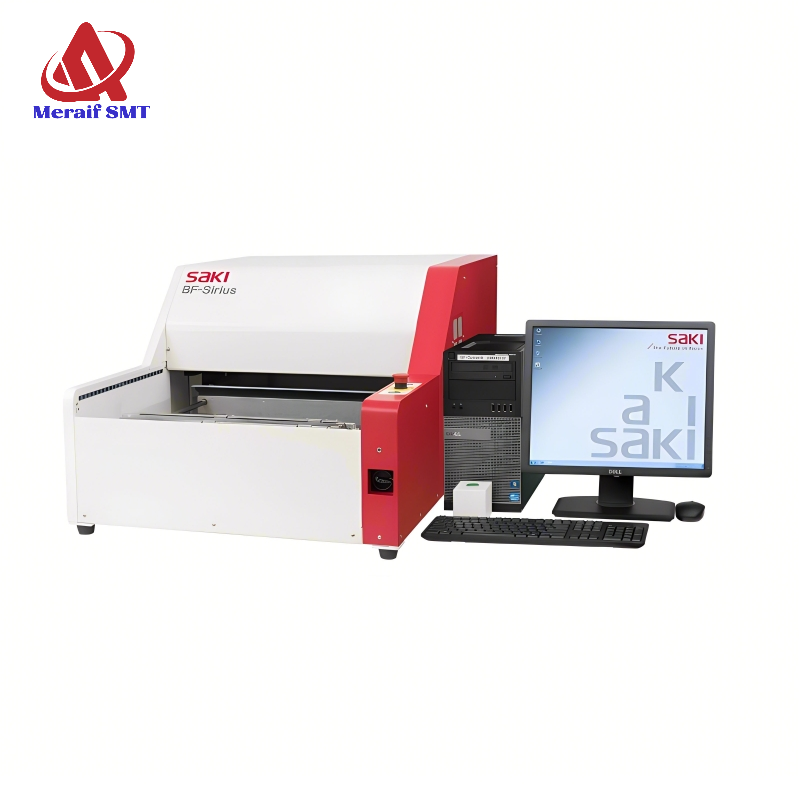

SAKI 3Xi M200 3D AOI SMT LINE AOI Picture Show:

EXHIBITION:

SMT LINE:

EXHIBITION:

SMT LINE: