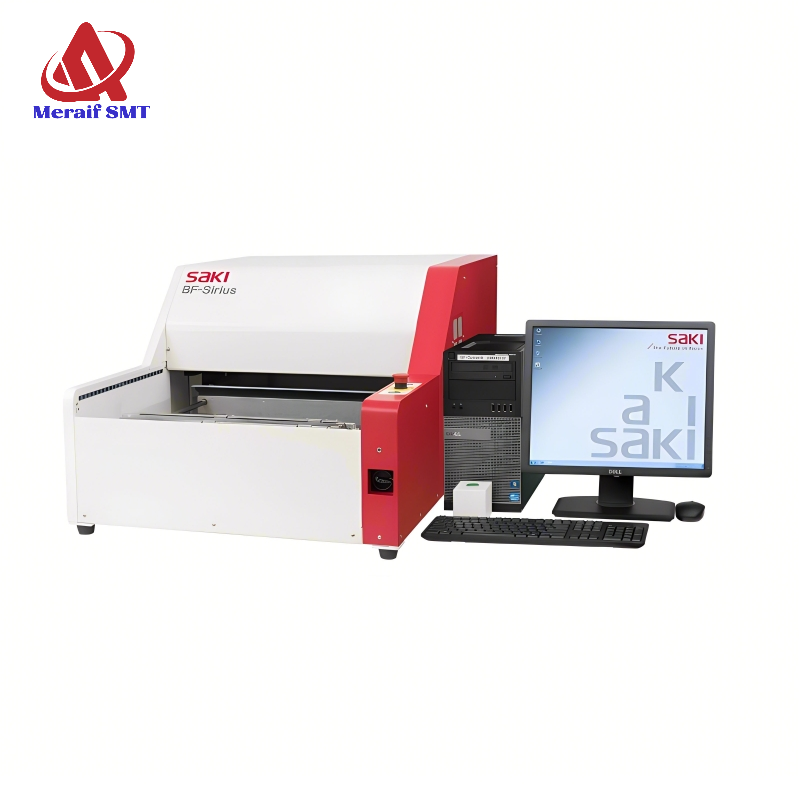

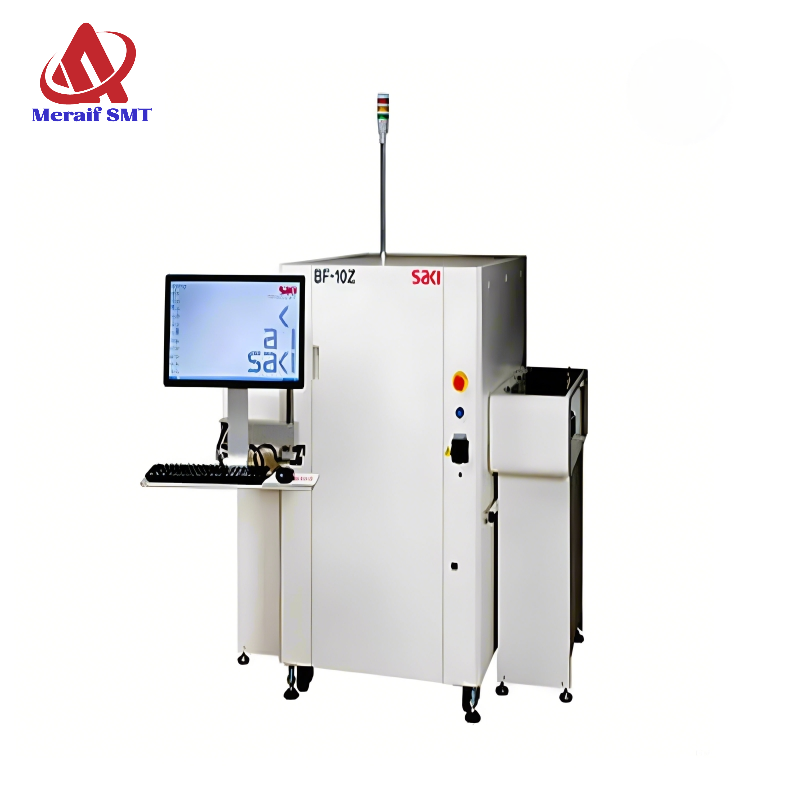

SAKI 3Xi M110 3D AOI SMT AOI 3D Automated Optical Inspection System AOI Equipment AOI Machine For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

SAKI 3Xi M110 3D AOI SMT LINE AOI Technical Parameters:

Model

3Xi-M110

Resolution

10µm-30µm

Target PCB Size

50W x 120L - 360W x 330L (1.97W x 4.73L - 14.17W x 12.99L)

50W x 120L - 360W x 510L ※ (1.97W x 4.72L - 14.17W x 20.07L)※

PCB Thickness

0.8mm - 4.0mm (0.031-0.157 in.)

PCB Warpage

2mm (0.08 in.) or less

PCB Clearance

TOP:60mm (2.36 in.) Bottom:40mm (1.57 in.)

Inspection Categories

Chip Type Parts, Diodes, Tantalum Capacitors, Aluminum Electrolytic Capacitors,

Module chips, Transistors, Power Transistors, Connectors, QFP, SOP, CSP, QFN, and BGA

Detector

Flat Panel 14bit 3M Pixel

X-ray Tube

110kV 30W, Closed X-ray Source

X-ray leakage

0.5μSvh or less

Conveyor Method

Flat belt transfer

Conveyor Height

880-920mm (34.65-36.22 in.)

Width Adjustment

Auto Width Adjustment

Operating System

Windows 10 IoT Enterprise2019 EMB 64bit (Microsoft)

Electric Power Requirement

Three - Phase ~200 +/-10%, 50/60Hz

Power Consumption

4.2kVA

Air Requirement

0.5 MPa, 20 L/min(ANR)

Usage Environment

15°C - 30°C / 15 - 80%RH (Non-condensing)

Noise Level

70.0dB or less

Dimensions W x D x H (Main body)

1380 × 2150 × 1500mm (54.34 x 84.65 x 59.06 in.)

Weight (Main body)

Aprox. 3,100 kg (6834.34 lbs)

SAKI 3Xi M110 3D AOI SMT LINE AOI Details:

The 3Xi-M110 from Saki Corporation is an Inline 3D-CT Automated X-ray Inspection System for PCB sizes from 50 x 140 mm to 360 x 510 mm. It utilizes Saki's exclusive Planar CT technology and micro-focus X-ray tube (4μm) to generate high-definition cross-sectional images with fewer slices. This system combines a highly accurate stage controlling systemwith twin-driven motors and high-precision linear scale to process the position information of each axis as part of the CT calculation to produce very high-definition cross-sectional imagery. The Planar-CT technology ensures that the top and bottom layers of double-sided PCBs are clearly separated for highly accurate inspection.It features automatic warpage compensation to correct distortion in X, Y and Z direction to reduce programming workload and increase inspection accuracy.

The 3Xi-M110 usesSaki's original algorithms to enable reconstruction of true 3D volumetric data to detect challenging defects such as Voids or Head-in-Pillow (HiP) (fully compliant with IPC standards). It includes self-diagnostic function which monitors the machine condition in real time. The function prevents sudden machine down time and allows for planned maintenance and service. It is available in an enclosure that measures 1380 x 2150 x 1500 mm and requires a 3-phase AC supply.

Features 1

Saki's planar CT technology captures hard-to-find defects

·The 3Xi-M110 ensures hidden solder joint quali- ty for bottom-electrode packages such as BGAs, LGAs,and QFNs

·PCT provides precise volumetric measurements and shape reconstruction to find voids,head-in- pillow(HiP),and other defects that are extremely difficult to identify

Features 2

High-speed &high-precision

·Optimized control features and high-speed FOV switching operation reduce cycle time up to 50%

·New x-ray imaging mode enables non-stop po- sitioning and maintains high-precision image quality

·New software function achieves even faster by activating a continuous capture mode that elimi-nates waiting &margin-time

·Double motor-driven system and high-precision linear scale by Magnescale assures precision and power

Features 3

Lightweight,rigid structure in a small footprint

·40%lighter hardware platform(3,100kg)and a 25%smaller footprint (1,380mm width)

·Saves floorspace,is easily installed,and improves production-line operability

·Light,but rigid cast iron frame for stable opera- tion and accuracy

·Optimized imaging range for PCBs up to 360x330mm (WxL)

·2-step image capture is available for larger 360x510mm (WxL)boards

Features 4

Reduced x-ray exposure

·Revolutionary X-ray tube reduces x-ray exposure up to 70%by powering on x-rays only at the mo- ment of image capture

·Exposure dose simulator lets the user monitor the radiation dose

·The method and magnification for releasing the X-rays can be set

·Periodic maintenance and spare parts are not re- quired

·Built-in monitoring system reports when the tube needs replacing

SAKI 3Xi M110 3D AOI SMT LINE AOI Picture Show:

EXHIBITION:

SMT LINE:

EXHIBITION:

SMT LINE: