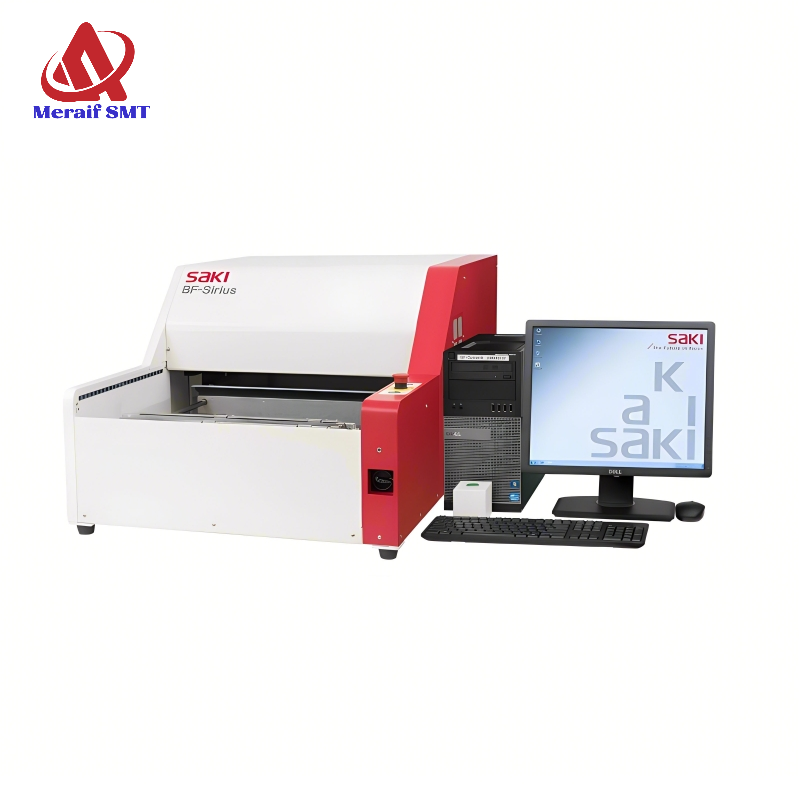

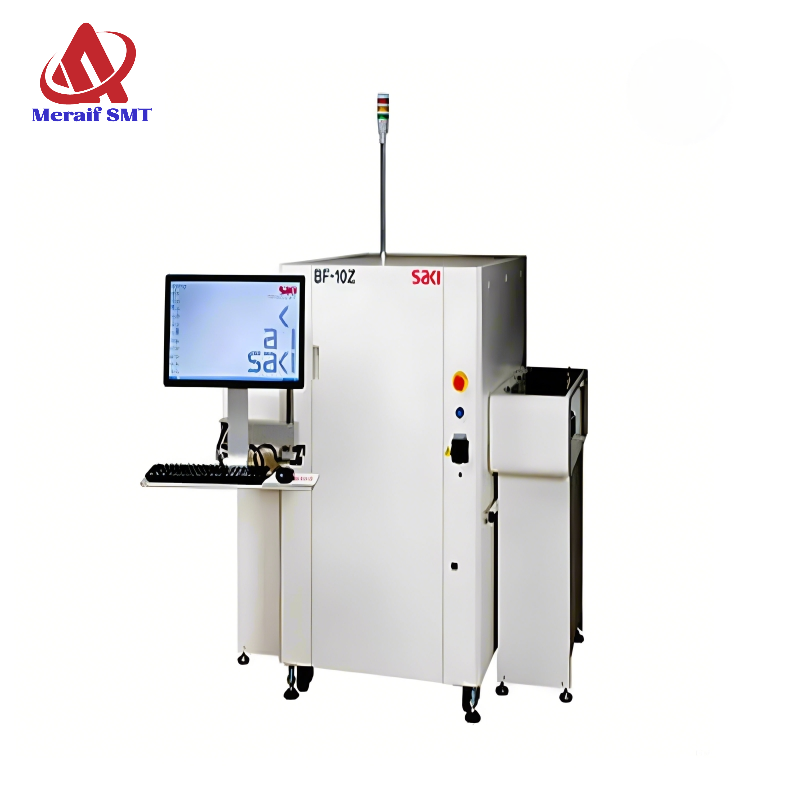

SAKI 2Di-LU1 2D AOI SMT AOI 2D Automated Optical Inspection System AOI Equipment AOI Machine For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

SAKI 2Di-LU1 2D AOI SMT AOI Technical Parameters:

|

MODEL |

2Di-LU1 |

|

Resolution |

18μm |

|

Target PCB Size

mm (in.)

|

Carrier:

50Wx60L-610Wx610Lmm(1.97Wx2.36L-24.02Wx24.02L in.)

Inspection area(Scan):

50Wx60L-460Wx500Lmm(1.97Wx2.36L-18.11Wx19.69 L in.)

|

|

PCB Thickness |

0.5-5.2 mm(0.02-0.20 in.) |

|

PCB Weight |

12 kg(26.46 lbs)or less |

|

PCB Clearance |

Top:130 mm(5.12 in.),Bottom:40 mm(1.57 in.) |

|

Heat Resistant

Temperature

|

70℃(158F)or lower |

|

Inspection

Categories

|

Solder inspection for THT(Copper,Blow Hole,Pin,Fillet,Absence of Solder,Bridge)

*Each defect name can be arranged freely by the system function

|

|

Transfer Conveyor

Method

|

Flat belt transfer |

|

Transfer Conveyor

Height

|

880-965 mm(34.65-37.99 in.) |

|

Operating System |

Windows 10 loT Enterprise 64 bit English Editon(Microsoft) |

|

Electric Power

Requirement

|

~200-240V+/-10%,50/60Hz,700VA |

|

Air Requirement |

0.5MPa,5L/min(ANR) |

|

Usage Environment |

15℃(59F)-30℃(86F)/15-80%RH(Non-condensing) |

|

Dimensions

WxDxH(Main body)

|

1040x1440x1500mm(40.94×56.69×59.06 in.) |

|

Weight |

Approx.750 kg,1653.47 lbs |

A 2D bottom-side inspection machine that automates the final process inspection of printed circuit board mounting, Bottom-Side AOI guarantees the solder quality of through-hole components after the selective, flow and dip soldering process. As board handling and PCB reversal is not required, efficiency is improved.

Efficiency

Equipment design accommodates mounting of large

Common operations with SMT process

High-speed Inspection

Rapid inspection with simultaneous full-board imaging

Saki’s unique line scan imaging method

Solder Detection

THT solder inspection detects several solder defects simultaneously

Extra Component Detection (ECD) inspection capability

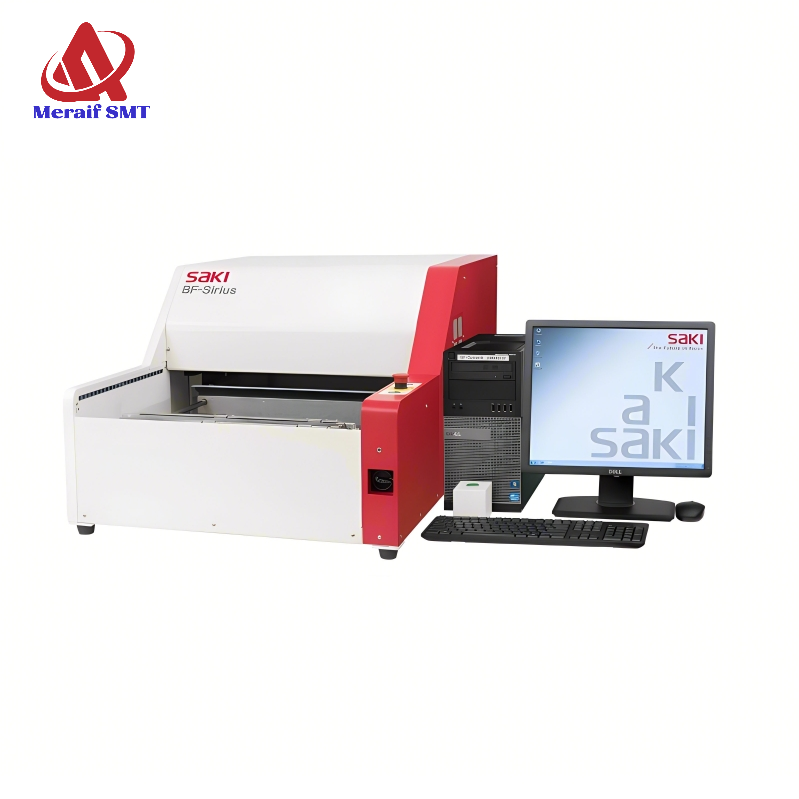

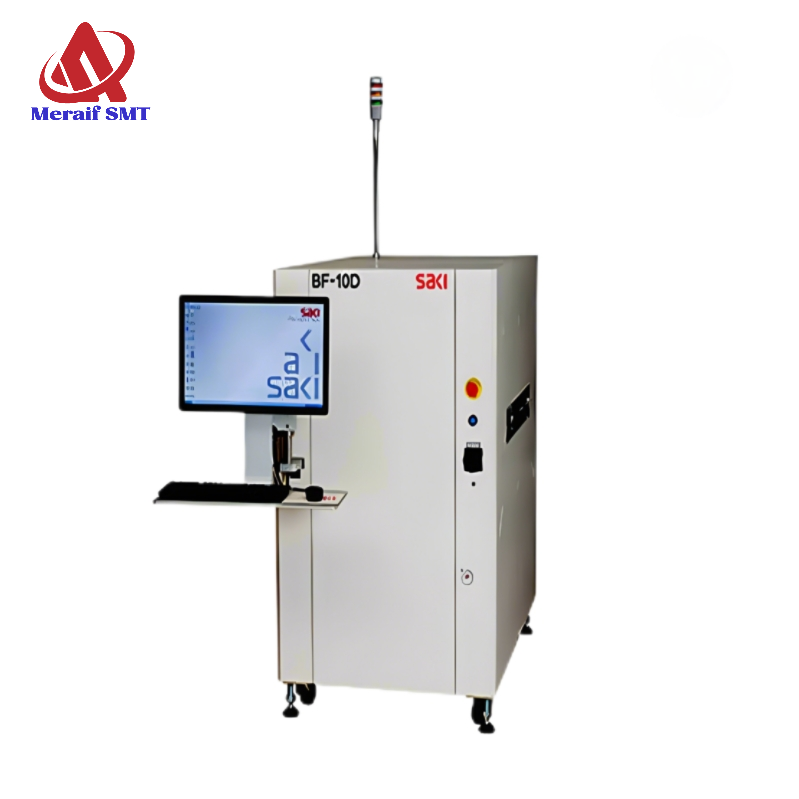

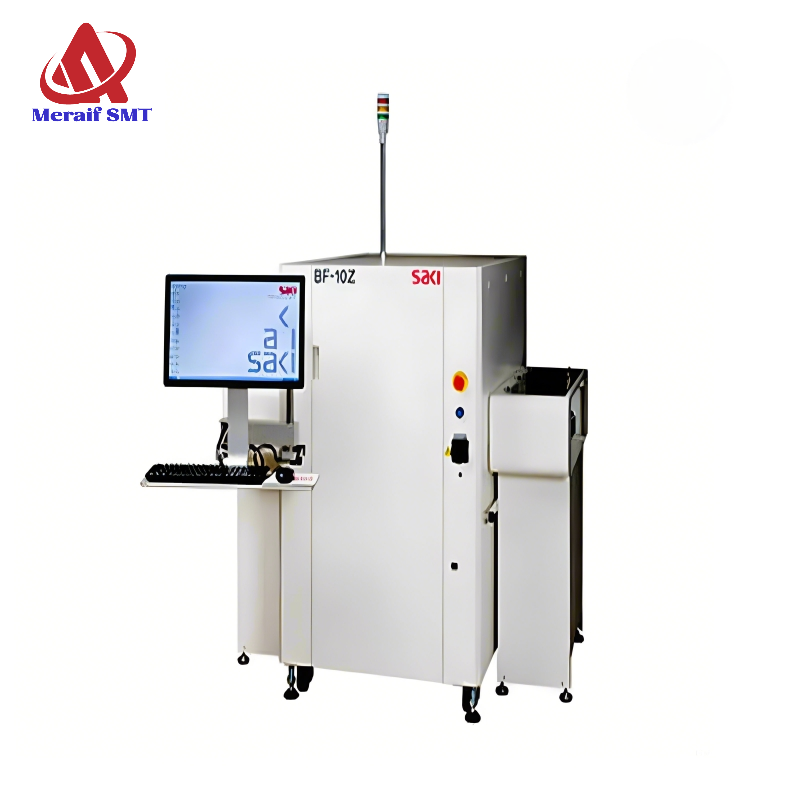

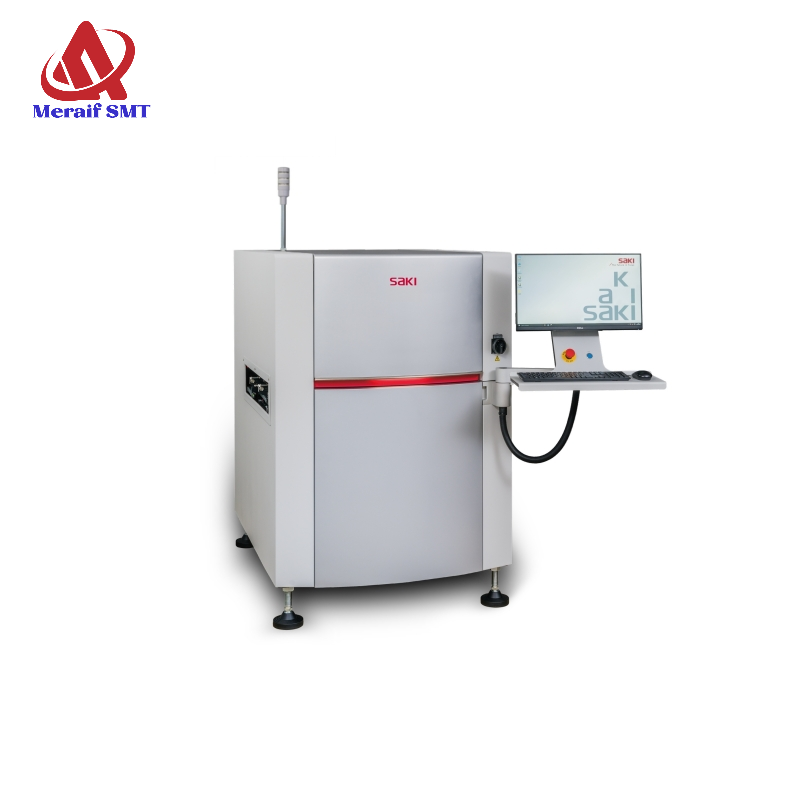

SAKI 2Di-LU1 2D AOI SMT AOI Picture Show:

EXHIBITION:

SMT LINE:

EXHIBITION:

SMT LINE: