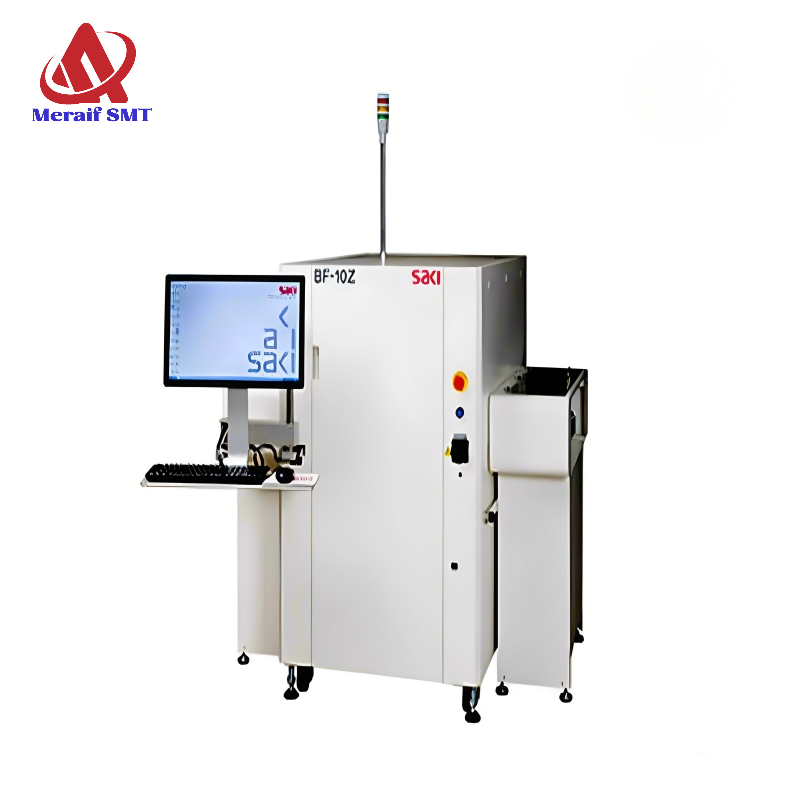

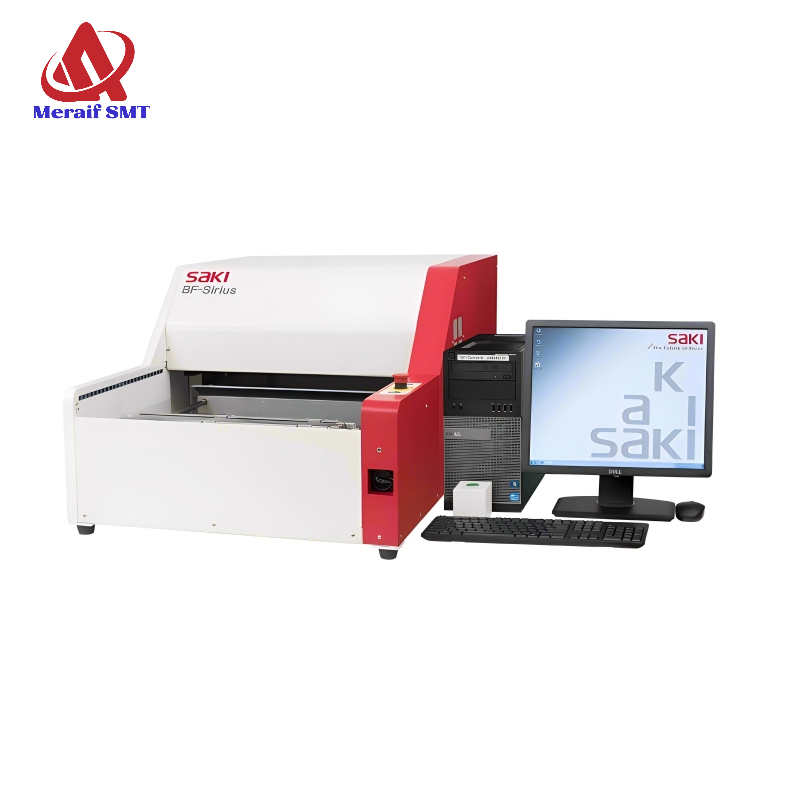

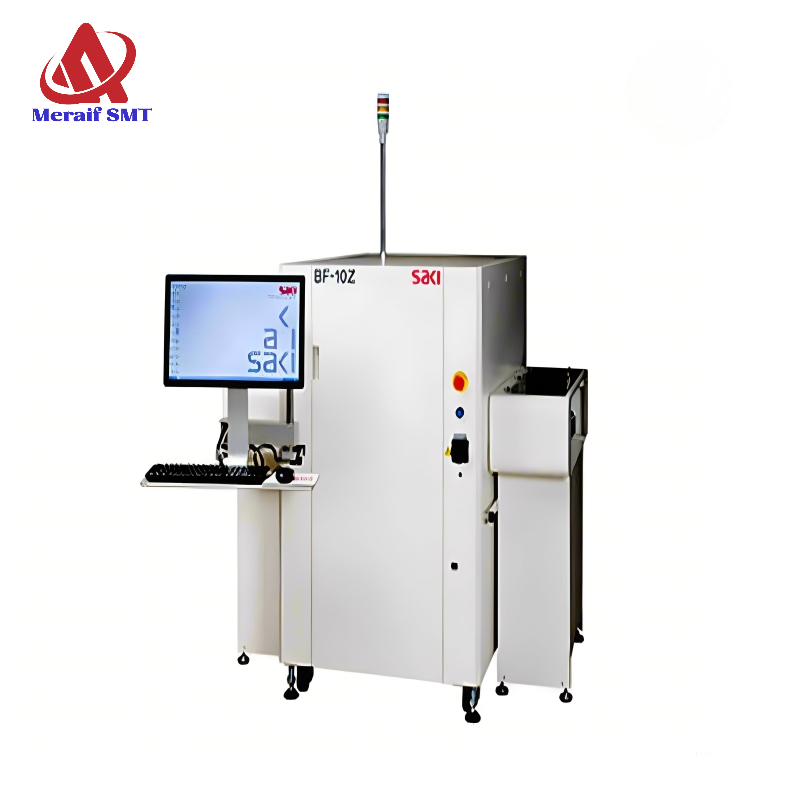

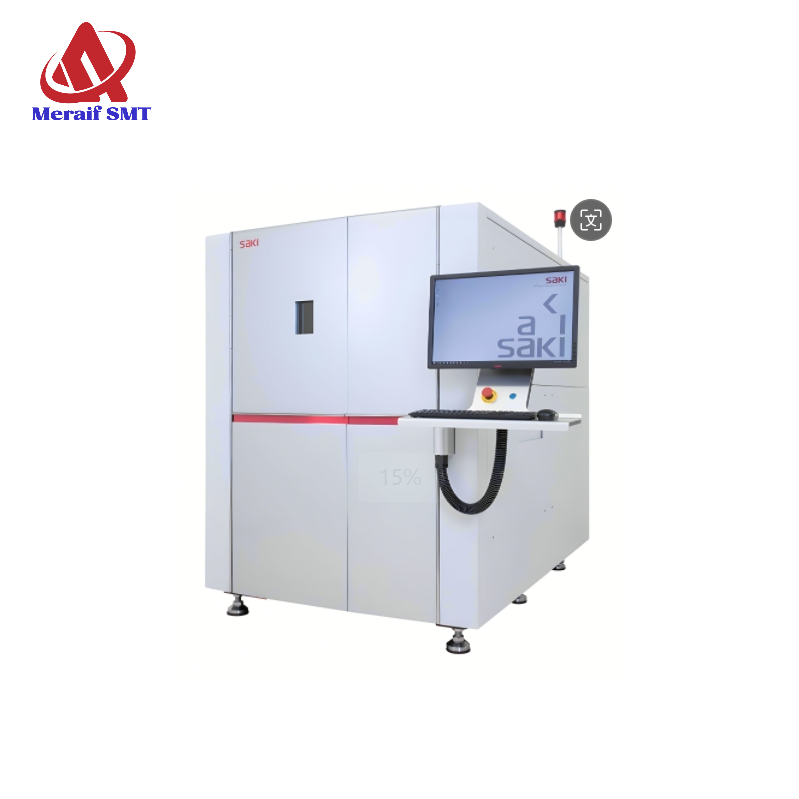

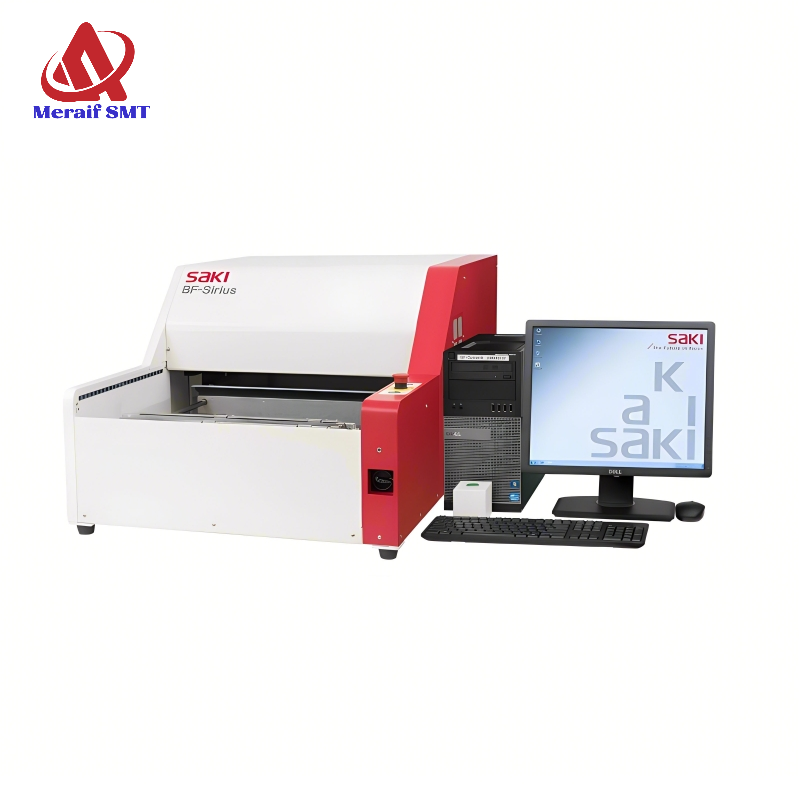

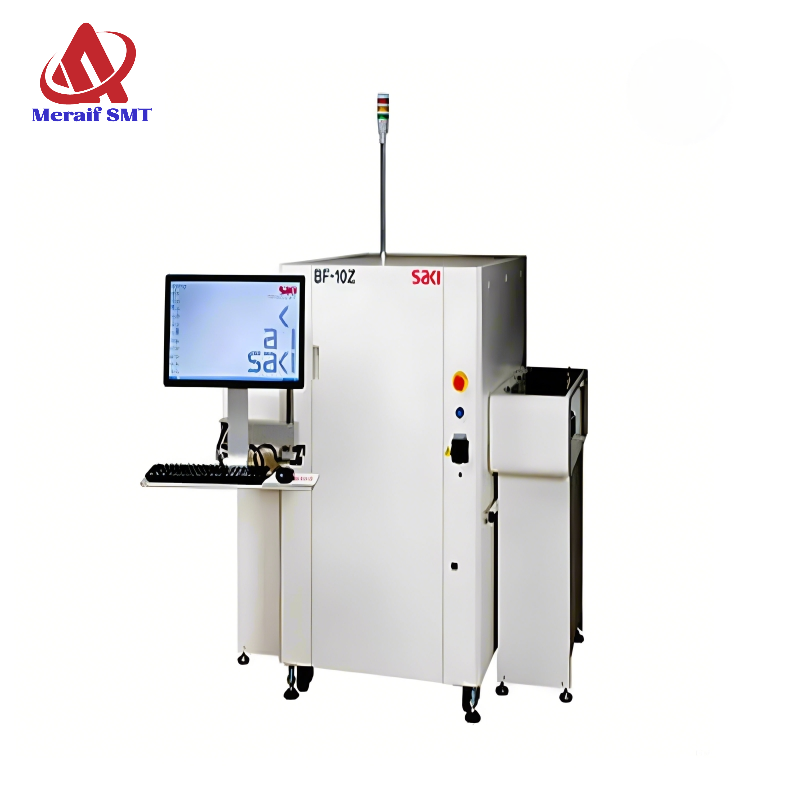

SAKI BF-10Z 2D AOI SMT AOI 2D Automated Optical Inspection System AOI Equipment AOI Machine For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

SAKI BF-10Z AOI SMT AOI Technical Parameters:

|

MODEL |

BF-10Z |

|

Resolution |

10μm,20μm (Selective Resolution System) |

|

Board Size |

50Wx60L-686Wx870Lmm(1.97Wx2.36L-27Wx34.25Lin.) |

|

Board Thickness |

0.6-5.0mm(0.02-0.196in.) |

|

Board Warp |

2mm(0.078in.)orless |

|

PCB Clearance |

Top:40mm(1.575in.)Bottom:40mm(1.575in.) |

|

Inspection

Categories

|

Presence/Absence, Misalignment, Tombstone, Reverse, Polarity, Bridge, Foreign material, Absence of solder, Insufficient solder, Lifted lead, Lifted chip, and Fillet defect. Each defect name can be arranged freely by the system function. |

|

|

|

|

Tact Time |

10μm:Approx.63sec.20μm:Approx.39sec. |

|

Image Scanning Time) |

10μm:Approx.15sec.x320μm:Approx.8sec.x3 |

|

Camera (Image processing) |

Line color CCD camera |

|

Lighting |

LED lighting system |

|

Transfer Conveyor Method |

Flat belt transfer |

|

Transfer Conveyor Height |

880-920mm(34.65-36.22in.) |

|

Transfer Conveyor Width Adjustment |

Auto width adjustment |

|

Operating System |

Windows 7 Professional |

|

Optional System |

BF-Editor/BF-RP1/BF-Monitor/BF-View |

|

Optional |

2D Barcode Recognition,Journal Printer |

|

(*1)If a PCB size is smaller than 686 Wx870 Lmm(27 Wx34.25 Lin.),Image scanning time will be shorter than these values.Shading process is performed when a PCB is loaded to the machine. |

|

|

Installation Specifications |

|

|

Electric Power Requirement |

Single phase~100-120V/200V-240V+/-10%,50/60Hz,800VA |

|

Air Requirement |

0.5MPa,5L/min(ANR) |

|

Usage Environment |

15℃(59F)-30℃(86F)/15-80%RH

(Non-condensing)

|

|

Dimensions(*2) |

1500Wx1360Dx1380Hmm(59.06 W x 53.54 D x 54.33 H in.) |

|

Weight |

Approx. 530 Kg (1168 lbs) |

|

(*2)Monitor and keyboard armis not included. |

|

The BF-10Z was developed especially for manufacturers building XL size panels, up to 686 x 870 mm (27.01 x 34.25 in.), for products such as communication base stations, server and storage assemblies, and LED back panels. The BF-10Z employs Saki's "Selective Resolution System," which enables users to operate in 10µm or 20µm resolution scanning modes. Users can select either mode, choosing the one that best matches accuracy and throughput needs. The BF-10Z's takt time is 48 seconds in 10μm mode, and 31.5 seconds in 20µm mode.

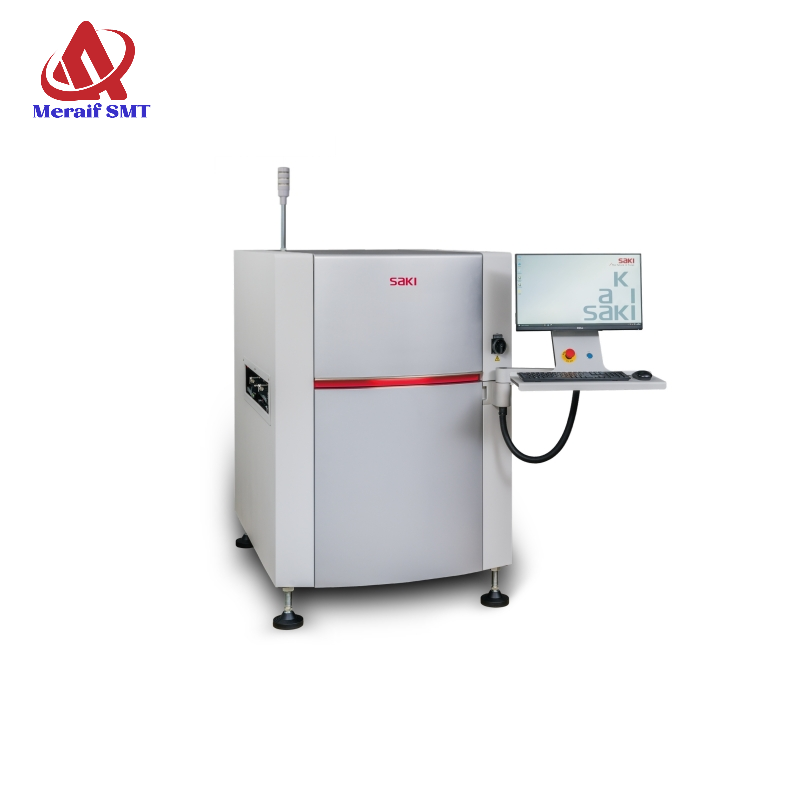

Line Scan Technology AOI for XXL-size PCBs

The new BF-10Z Automated Optical Inspection System employs Saki's unique Line Scan Technology for inspecting PCB panels up to m686 imes870 mm (27.01 in.x 34.25 in.)-a 40%increase in scanning area over Saki's previous XXL model.The BF-10Z is ideal for manufacturers building oversized products like communication base stations,server &storage assemblies and LED back panels.

XXL Inspection in a Compact Footprint

With the BF-10Z,Saki incorporates an innovative scanning method called “Multi-threading”.This enables BF-10Z to inspect XXL-size panels within its compact body,requiring the smallest production floor space of any system in its class.

Saki’s Innovative Coaxial TopLight

- the Best Lighting for Solder Inspection

Like all Saki's 2D AOI Systems,the new BF-10Z uses Saki's powerful Coaxial TopLight concept that illuminates the PCB surface from a 90 degree,perpendicular angle.Coaxial TopLight eliminates shadowing when shorter components are located next to much taller ones.Component libraries created with Coaxial TopLight are fully transportable -from location to location,board to board,and machine to machine.

Need Traceability?

Like the rest of Saki's 2D AOI Family,the BF-10Z can be equipped with both 1D &2D barcode (QR code and data matrix)reading capability.This option makes assembly tracking and defect monitoring more effective and efficient.

Selective Resolution System

For manufacturers building XXL assemblies with ultra-small components like 0402 (01005)or 0.38 mm (0.015 in.)pitch ICs,Saki has equipped the new BF-10Z with a powerful 10 μm resolution scanning mode for accurate inspection of the micro-sized features of these devices.When operating in 10μm resolution scanning mode,the BF-10Z can still inspect a maximum-size panel in 63 seconds.Now users can select between either resolution operating modes,choosing the one that best matches their accuracy needs with their throughput needs.

High Throughput - with High Resolution

When running in its standard 20μm resolution mode,the new BF-10Z boasts a 10%increase in scanning speed over the previous XXL model, even with its 60%increase in scanning area.The BF-10Z's tact time for a 686 imes870~{ m mm}~(27.01~{ m in.x}~34.25~{ m in.}) panel is 39 seconds.

XXL-Size Flexibility

The BF-10Z features a 40 mm(1.575 in.)clearance on both the top and bottom sides,providing enough room for the largest SMT components.This means the BF-10Z can be installed anywhere in the assembly process:post-paste,post-placement,post-reflow,or after hand soldering.

Rely on the BF-10Z’s Real Time Defect

Management & Analysis

The built-in real-time SPC functionality of the BF-10Z helps you to combine exceptional quality with high productivity for your SMT process.For more efficiency,network the BF-10Z with Saki's family of optional AOI enhancements including the BF-Editor (off-line programming),the BF-RP1 (remote repair station),the BF-View (AOl process management platform)and the BF-Monitor (SPC&Quality Management Environment).

SAKI BF-10Z AOI SMT AOI Picture Show:

EXHIBITION:

SMT LINE:

EXHIBITION:

SMT LINE: