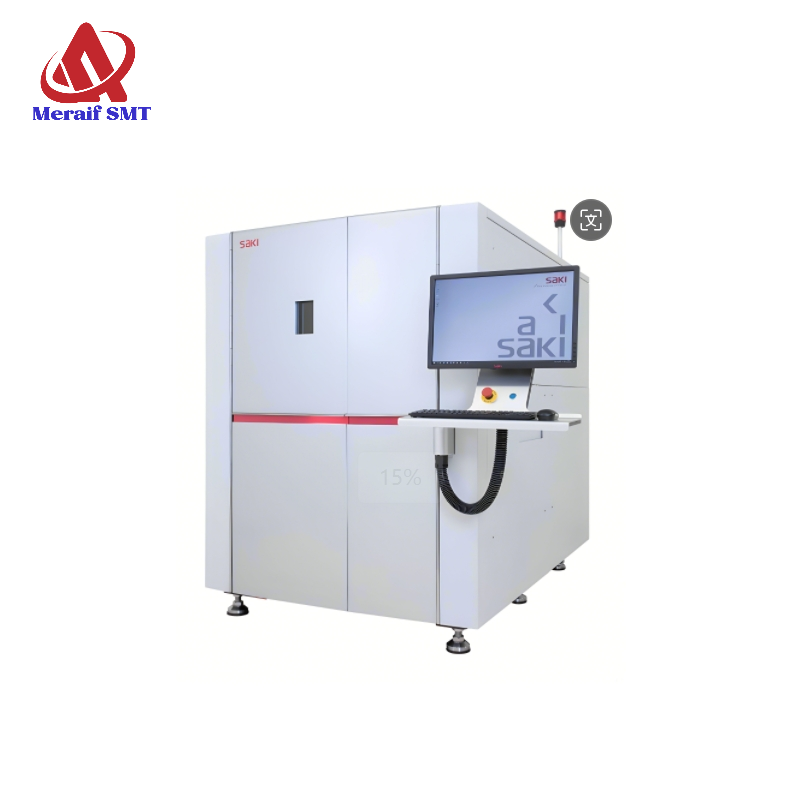

SAKI BF-Tristar II 2D AOI SMT AOI 2D Automated Optical Inspection System AOI Equipment AOI Machine For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

SAKI BF-Tristar II 2D AOI SMT AOI Technical Parameters:

|

MODEL |

BF-Tristar |

|

Resolution |

10 μm |

|

Board size |

70x50-330x250 mm,2x2.8-10x13 in. |

|

Board thickness |

0.6-2.5 mm,24-100 mils |

|

Board warp |

+/-1 mm,40 mils |

|

PCB clearance |

Top:30 mm,Bottom:30 mm |

|

Rotated component support |

Available for 0-359°rotation [unit of 1] |

|

Inspection categories |

Presence/Absence,Misalignment,Tombstone,Reverse,Polarity,Bridge,Foreign material,Lifted Chip,and Fillet defect.Each defect name

can be changed freely by system function.

|

|

Tact time*1*2 |

Approx.25 sec. (250×330 mm) |

|

Image scanning time*1 |

Approx.15 sec. (250×330 mm) |

|

Camera[image processing] |

Line color CCD camera |

|

Lighting |

LED lighting system |

|

Transfer conveyor method |

Flat belt transfer |

|

Transfer conveyor height |

900+/-20 mm,36+/-0.8 in |

|

Transfer conveyor

width adjustment

|

Automatic |

|

Operating system |

Windows 7 English Version |

|

Optional system |

BF-Editor/BF-RP1/BF-Monitor/BF-View |

|

Optional |

2D Barcode Recognition,Journal Printer |

|

*1 If PCB size is smaller than 250x330 mm,Imagescannig timewill be shorter than this values.

*2 Including Image Scanning Time.

|

|

|

System Requirements |

|

|

Electric power requirement |

Single phase~200-240V+/-10%,50/60Hz,1300VA |

|

Air requirement |

0.5MPa,5L/min (ANR),73PSI,0.18CFM |

|

Usage environment |

15℃[59F]-30℃[86F]/15-80%RH(Non-condensing) |

|

Dimensions WxDxH[Main body] |

850x1380x1330 mm,33.46x54.33x52.32 in. |

|

Weight |

Approx.450 kg,992 lbs |

Saki's 2D AOI systems employ a telecentric lens optical system to capture the clearest images. The system corrects for brightness of the entire sample and compensates for position misalignment in real time while the image is scanned, assuring inspection results that are accurate, reliable, and repeatable over time. A variety of algorithms and lighting types are available to deal with a wide range of industry inspection requirements. Multiple data handling capabilities are provided, such as switching settings by barcode reading and data output to the customer’s data server to flexibly cope with line requirements.

The Highest Speed Throughput

Applying Saki's unique Line Scan Technology,the BF-Tristar achieves simultaneous inspection of double-sided PCB's to create a highly efficient production process.The creation of inspection recipes,scanning and inspection can be done at the highest speed by applying the newly developed “Master-Slave PC System”,in which multiple cameras and PC's process the PCB image in parallel.BF-Tristar is able to inspect both sides of an M size board in less than 25sec,counted from the time when PCBis taken into the machine.

Process of Inspection

Also applicable as the final test after in-circuit test and function test priorto shipment.

*The system employs 3 types of high intensity LEDs: Top light:red LED,Side light:white LED,and Low light: blue LED.

Easy and Friendly Operation and Program Control

NC data extraction and program tuning of double- sided PCB's can be done with the ease of single- sided PCB's.1 program data can be used to control 1 PCB model.Change of PCB model at production can be completed at once.

High Accuracy

10 μm high resolution imaging,matched with line color CCD sensor camera,enables inspection of high density mounted 01005[0402]chips.Tricolor MLT Lighting [*]improves inspection accuracy of letter recognition,polarity,and solder fillets.

Auto Focusing Function

Auto Focusing Function provides stable environment of image scanning.

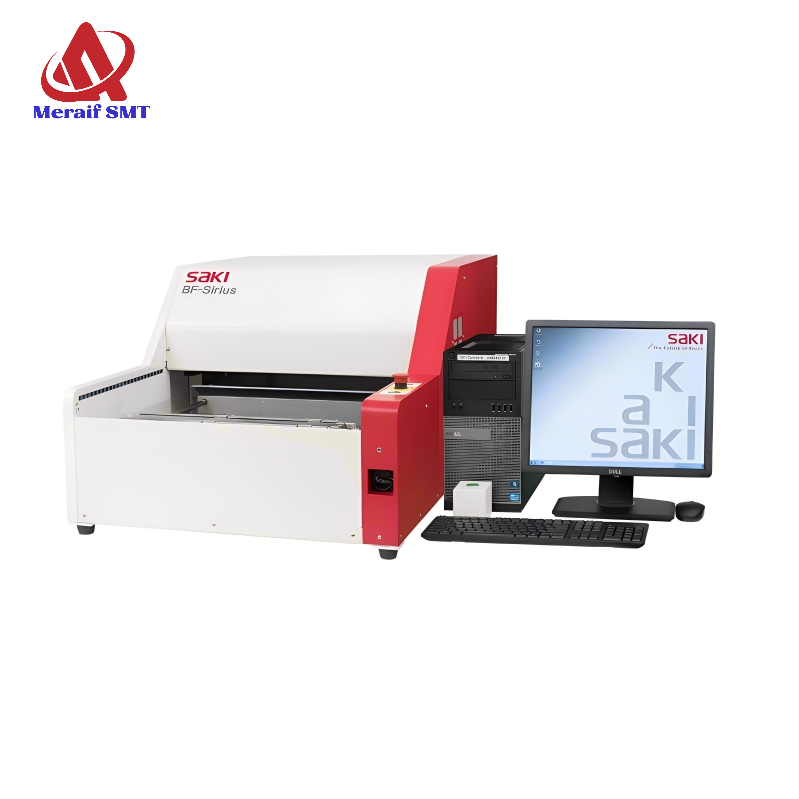

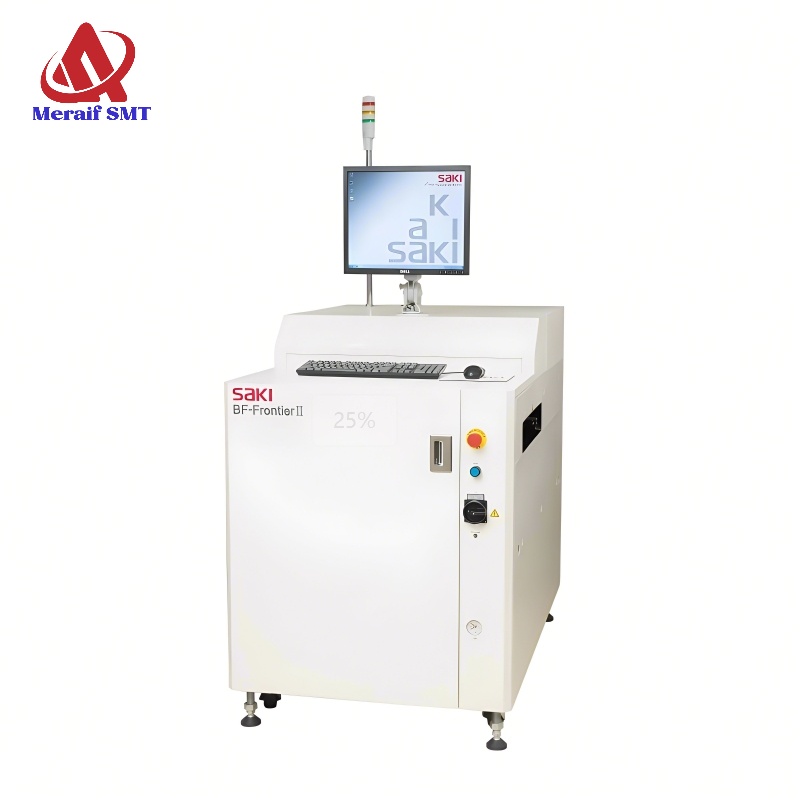

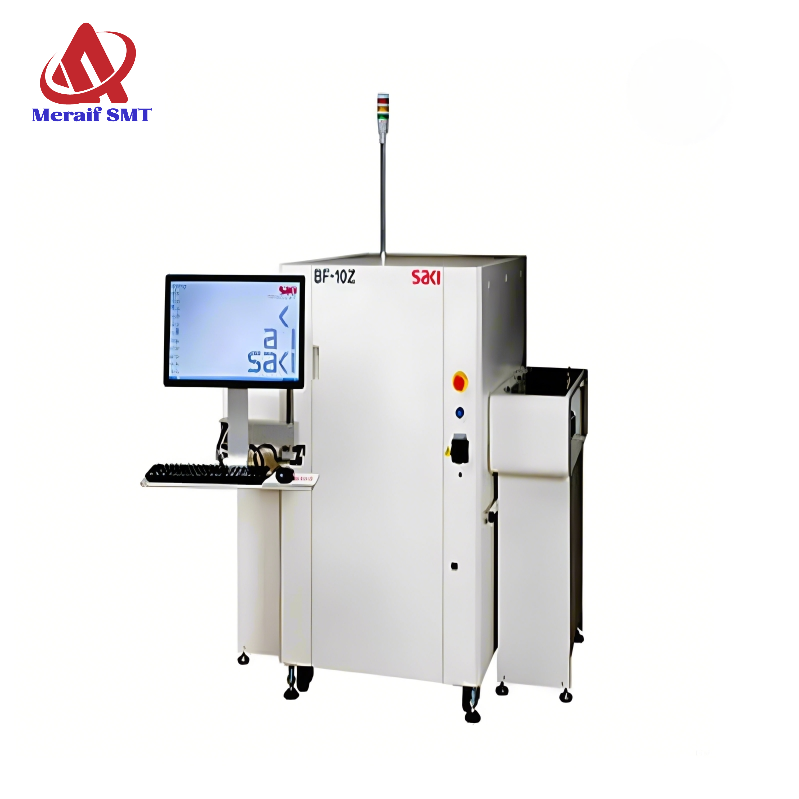

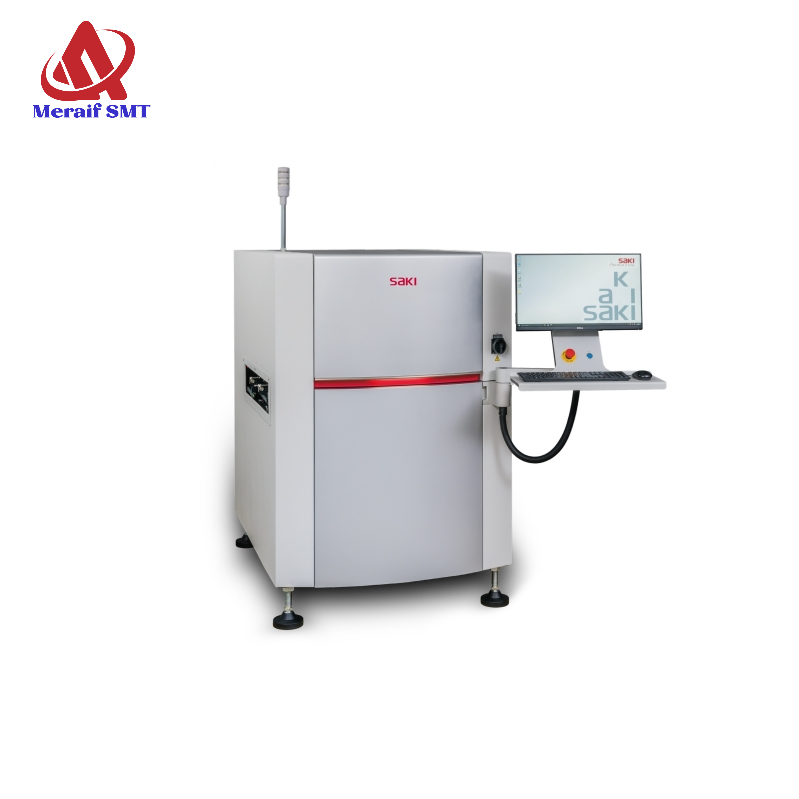

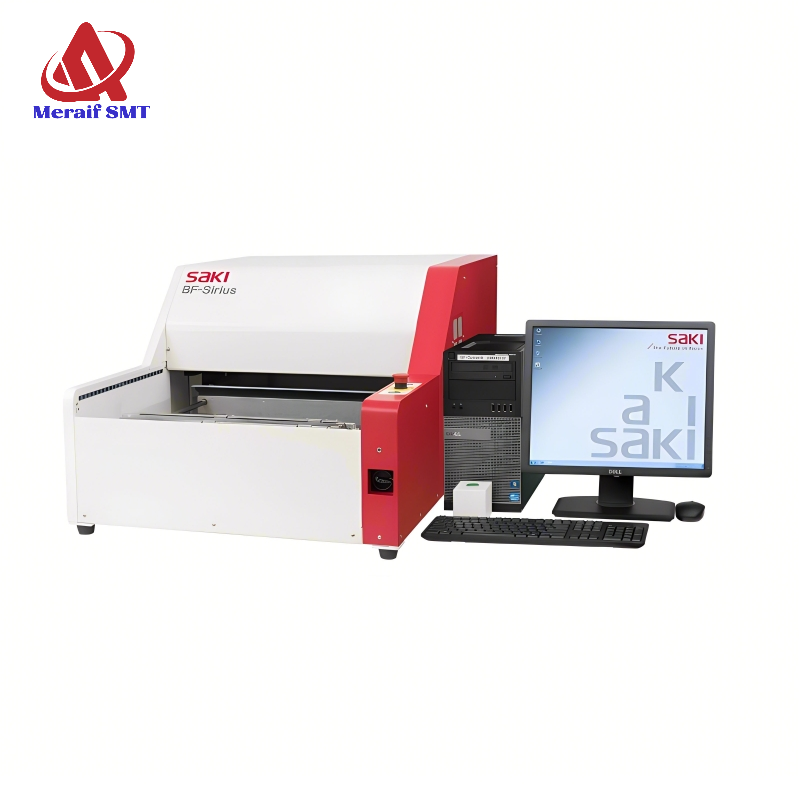

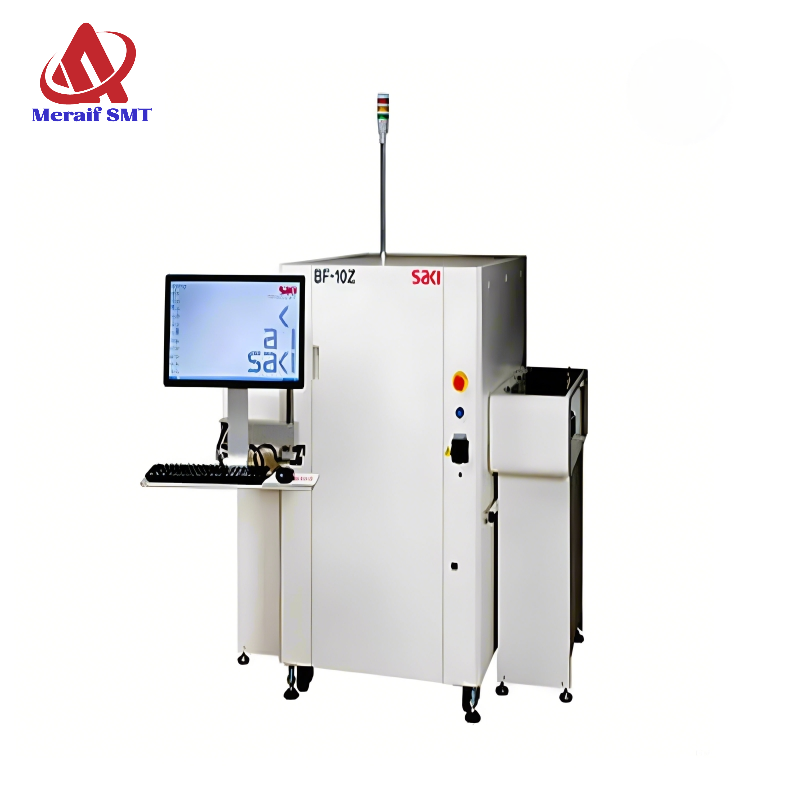

SAKI BF-Tristar II 2D AOI SMT AOI Picture Show:

EXHIBITION:

SMT LINE:

EXHIBITION:

SMT LINE: