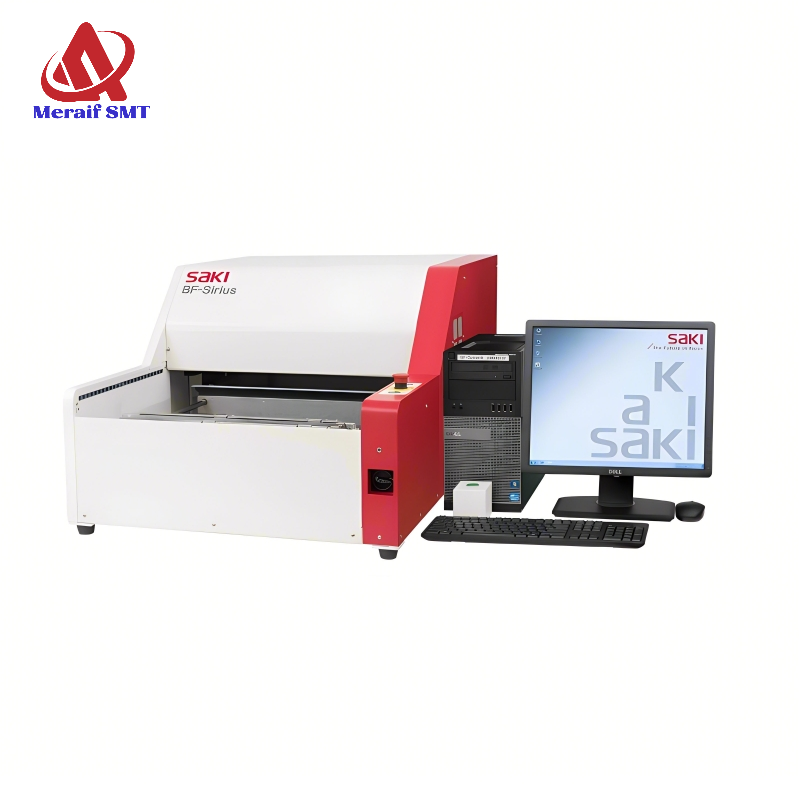

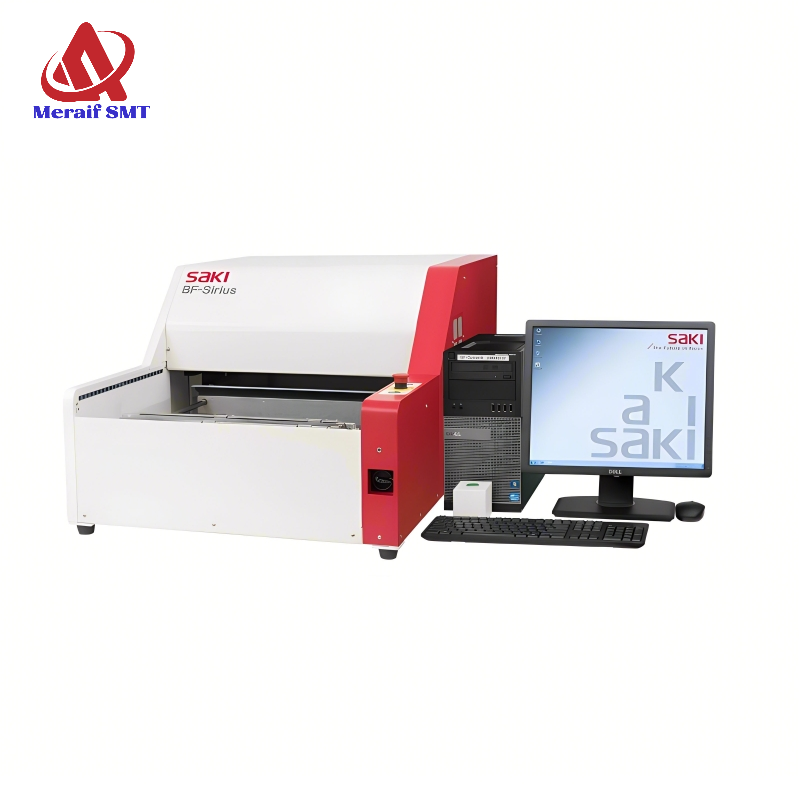

SAKI BF-Sirius 2D AOI SMT LINE AOI 2D Automated Optical Inspection System AOI Equipment AOI Machine For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

SAKI BF-Sirius 2D AOI SMT LINE AOI Technical Parameters:

|

MODEL |

BF-Sirius |

|

Resolution |

18 μm |

|

Board Size |

50x50-500×460mm |

|

Board Thickness |

0.6-2.5 mm,24-100 mils |

|

Board Warp |

+/-2 mm,79 mils |

|

PCB Clearance |

Top:40 mm,Bottom:60 mm |

|

Rotated Component Support |

Available for O-359°rotation [unit of 1] |

|

Inspection Categories |

Presence/absence,misalignment,tombstone,reverse,polarity,bridge,foreign material,absence of solder,insufficient solder,lifted lead,lifted chip,and fllet defect.Each defect name can be changed freely by system function. |

|

Tact time*1*2(460x500 mm) |

Approx.18 sec. |

|

Image Scanning Time*1[460×500 mm] |

Approx.10 sec. |

|

Camera [lmage Processing] |

Line color CCD camera |

|

Lighting |

LED lighting system |

|

Operating System |

Windows XP english version |

|

Optional System |

BF-editor/BF-RP1/BF-view |

|

Optional |

2D Barcode recognition,journal printer,OK/NG signal out |

|

|

External control box |

|

*1If PCB size is smaller than 460×500 mm,Imagescannig time wilbe shorter than these values.*2 Including image scanning time. |

|

|

Installation Specifications |

|

|

Electric power requirement |

Single phase ~100-120V/200-240V+/-10%,50/60 Hz |

|

Power consumption |

700 VA |

|

Air requirement |

Not needed |

|

Usage environment |

15℃ [59F]-30℃(86FJ/15-80%RH (Non-condensingl |

|

Noise level |

60.5 dB |

|

Dimensions (mainbodyl |

800 (W)x1280[D]x600(H)mm |

|

Weight [main body] |

Approx.175 kg,386 lbs |

BF-Sirius is a high-speed 2D AOI benchtop model that supports large size PCBs up to 500 x 460 mm (19.7″ x 18.1″). The small footprint minimizes cost and floorspace requirements. The system can inspect multiple SMT processes including selective solder and conformal coating.

High Resolution Optical System

With a superior resolution of 18μm and a scanning line color CCD camera,the BF-sirius provide accurate and stable inspection results.Solder fillets on components as small as the high density mounted 0201 [0603]chip,as well as IC's with0.4 mm pitch lead are easily inspected and analyzed.

High Throughput

BF-Sirius has Saki's originalalternate scanning system that captures several lighting images in one scanning.Newly developed color capturing system enable to make scanning speed twice faster than previous model.BF-Sirius takes only 10 seconds to capture L-size board [460 mm x500 mm].Overall tact time including inspection also become shortened dramatically.

New Interface

Renewed user interface makes it easier to set up inspection data by using pre-installed Saki standard library.And optional new function KPK,that finds out the difference between surface of the board and the surface of component automatically, simplifies to detect missing component.This realizes time reduction for inspection data making at launching production.

Advantage of Line Scan Visual Inspection

Extra components on the board can be detected only by setting up one inspection window on the whole board.It is realized by the advantage of line scan method.

Coaxial Overhead Light

Soldering condition is inspected by illuminant irradiation of coaxial overhead lighting.Inspection is not affected by shadowing by neighboring tall components,therefore same libraryisavailable at any location on the board.

Flexibility

BF-Sirius has 40 mm clearance at the top side of the board and 60 mm at the bottom side.It enables most of the PCBs with tall components.In addition,BF-Sirius can be used in any stage of the PCB production process from post-print,post-mounter,and post-flow/reflow,or manual mounting.

Traceability

Optional function of BF-Sirius can read all types of barcode and 2D code on the board.Inspection output is reported with code number.It enables easy SPC data handling and log data management on manufacturing lines.

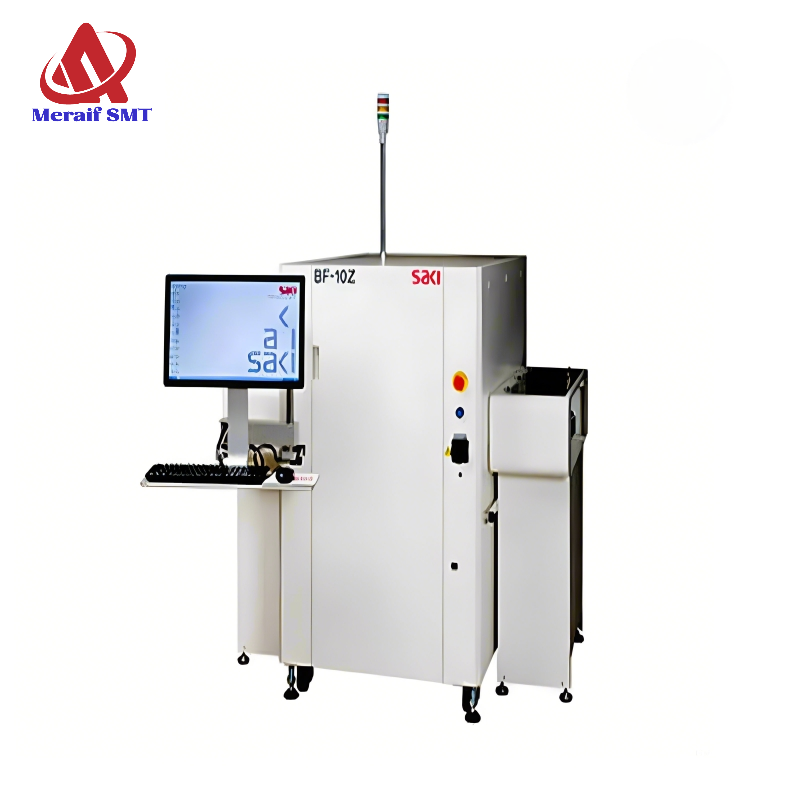

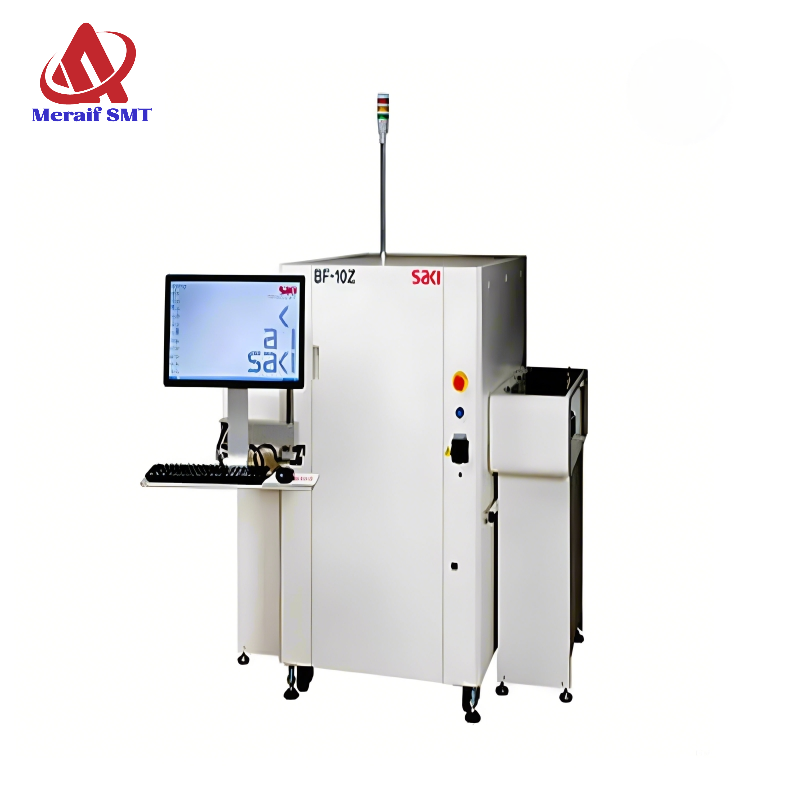

SAKI BF-Sirius 2D AOI SMT LINE AOI Picture Show:

EXHIBITION:

SMT LINE:

EXHIBITION:

SMT LINE: