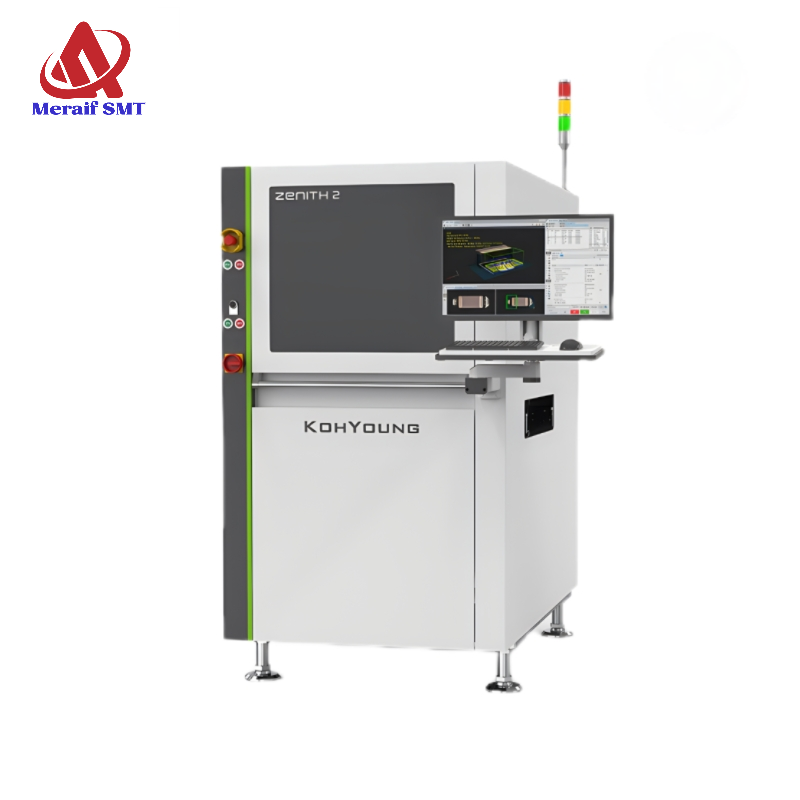

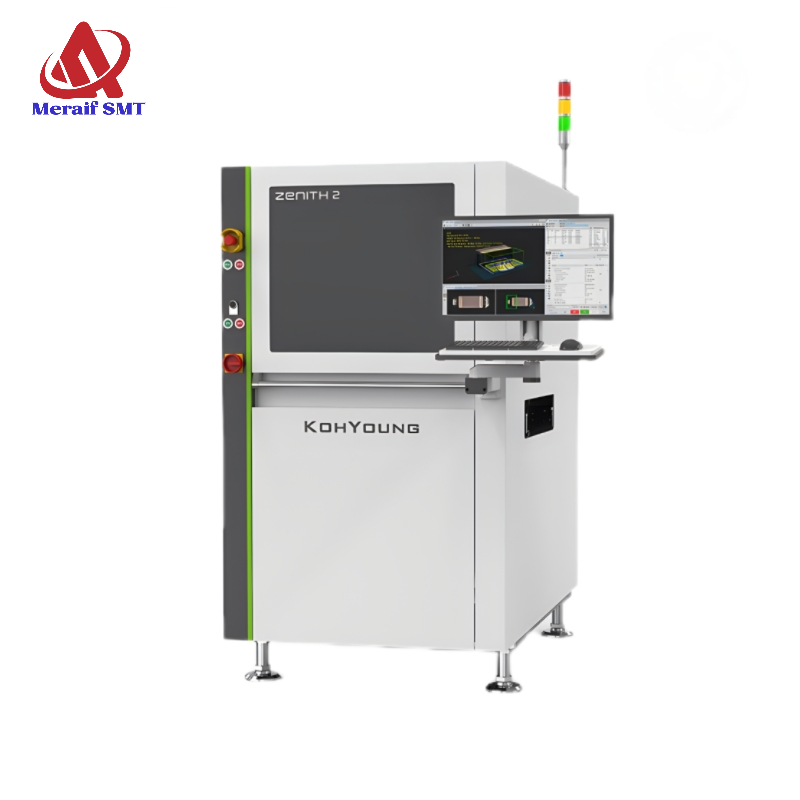

KOH YOUNG Zenith 2 3D AOI SMT AOI 3D Automated Optical Inspection System AOI Equipment AOI Machine For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

KOH YOUNG Zenith 2 3D AOI SMT AOI Technical Parameters:

Zenith 2

L

L

XL

Single Lane

Dual Lane

Single Lane

Dual Lane

Single Lane

Dual Lane

Max.PCB Size(XxY)

510x510mm

Single Mode°

330x510mm*

Single Mode°

510x510mm*

Single Mode°

510x580mm

330x580mm*

510x580mm*

Dual Mode

Dual Mode

Dual Mode

510x320mm

330x320mm*

510x320mm*

Min.PCB Size

50x50mm(2.0x2.0in)

PCB Thickness

0.4~5mm(0.02~0.20in)

0.4~5mm(0.02~0.20in)

0.4~8mm*(0.02~0.31in)

Max.PCBWeight

4kg(8.8lbs)

4kg*(8.8lbs)

MachineWeight(Approx.)

750kg

750kg

800kg

[SingleLane] 750kg*(1653.5lbs)

Bottom Clearance

50mm(2.0in)

Supplies

±220Vac,1Phase,50/60Hz,5Kgf/cm²(0.45Mpa)

W

1000mm(39.4in)

1000mm(39.4in)

1200mm(47.2in)

D

1530mm

1710mm

1530mm

1710mm

[SingleLane] 1530mm*(60.2in)

H

1805mm(71.1in)

1805mm(71.1in)

1805mm(71.1in)

Side-View

X

0

0

*Side-View Camera Option Specifications.

KOH YOUNG Zenith 2 3D AOI SMT AOI Details:

(20.1x20.1in)

(13.0x20.1in)

510x510mm

(20.1x20.1in)

(20.1x20.1in)

700x690mm

(27.6x27.2in)

(20.1x22.8in)

(13.0×22.8in)

510x580mm

(20.1x22.8in)

(20.1x22.8in)

700x580mm

(27.6x22.8in)

(20.1x12.6in)

(13.0x12.6in)

510x320mm

(20.1x12.6in)

(20.1x12.6in)

700x320mm

(27.6x12.6in)

0.4~5mm(0.02~0.20in)

10kg(22.0lbs)

(1653.5lbs)

(1653.5lbs)

(1763.7lbs)

800kg(1763.7lbs)

(60.2in)

(67.3in)

(60.2in)

(67.3in)

1710mm(67.3in)

Camera Option

Availability

Revolutionary True 3D AOI with Incomparable Inspection Capabilities

AI-powered AOI Solutions Reduce False Calls and Escapes:Zenith 2 is blazing a trail for AOI systems with novel SMT process management tools by combining advanced vision algorithms with innovative high-resolution optics, allowing a wider inspection coverage including advanced tall component inspection.

AOI Technology

Overview:Zenith eliminates all the sources of defects using full 3D measuring inspection equipment skills. Using patented True 3D technology, the Zenith measures true profilometric component shapes including foreign materials, patterns and solder joints with True 3D capabilities to overcome inspection challenges.

FEATURES:Koh Young America sets the standard in the electronics manufacturing industry with its cutting-edge inspection technologies. Central to its offerings is the patented True 3D inspection technology, ensuring unparalleled accuracy in defect detection across components and solder joints. Koh Young combines high-speed, precision inspections with advanced foreign material detection and AI-powered analysis, enhancing decision-making and process control. Its systems are designed for seamless integration into existing production lines and feature user-friendly interfaces for easy operation. With comprehensive SPC tools and robust customer support, Koh Young America is dedicated to improving manufacturing efficiency, quality, and reliability, reinforcing its commitment to driving customer success worldwide.

What is AUTOMATED OPTICAL INSPECTION?

AUTOMATED OPTICAL INSPECTION:Automated Optical Inspection (AOI) is a crucial technology used in the manufacturing and assembly process to ensure the quality of products, particularly in the electronics industry. It involves the use of optical systems, such as cameras and specialized software, to visually inspect printed circuit boards (PCBs), components, and assemblies for any defects or deviations from the intended design.

SOLUTIONS:Zenith eliminates all the sources of defects using full 3D measuring inspection equipment skills. Using patented True 3D technology, the Zenith measures true profilometric component shapes including foreign materials, patterns and solder joints with True 3D capabilities to overcome inspection challenges.

Manufacturing applications

Applications:Koh Young America’s Automated Optical Inspection (AOI) technology revolutionizes manufacturing processes with its patented True 3D inspection capabilities. This technology is critical for ensuring the highest quality in electronic assemblies by accurately detecting defects and ensuring compliance with stringent quality standards. Designed for high-speed and precision, it significantly enhances production efficiency by reducing manual inspection needs and minimizing downtime. The integration of AI for data analysis and decision-making further streamlines operations, making Koh Young’s AOI solutions a key asset for manufacturers seeking to optimize quality control and maintain a competitive edge in the fast-paced electronics industry.

BENEFITS:Koh Young America’s Automated Optical Inspection (AOI) technology revolutionizes manufacturing processes with its patented True 3D inspection capabilities. This technology is critical for ensuring the highest quality in electronic assemblies by accurately detecting defects and ensuring compliance with stringent quality standards. Designed for high-speed and precision, it significantly enhances production efficiency by reducing manual inspection needs and minimizing downtime. The integration of AI for data analysis and decision-making further streamlines operations, making Koh Young’s AOI solutions a key asset for manufacturers seeking to optimize quality control and maintain a competitive edge in the fast-paced electronics industry.

Incomparable True 3D Inspection Performance

3d inspection performance:The Zenith AOI series is the only solution in the industry to base its inspection criteria according to the IPC-610 standards for electronic assembly acceptability requirements. Koh Young’s quantitative True 3D measurement- based approach allows a wider inspection coverage including advanced tall component inspection.

The Zenith 2 delivers clear and concise AOI measurement to accurately identify multiple defects such as: Missing Solder, Offset, Polarity, Upside Down, OCV/OCR, Solder Fillet, Billboarding, Lifted Lead, Lifted Body, Tombstone, Bridging, and more.

High Accuracy and Speed

Demanding Production Line:Without sacrificing accuracy and speed, the Zenith Alpha combines mechatronics technology with cutting- edge measurement capabilities to yield high throughput suitable for demanding production lines.

Powerful Side-View Camera

optional side view:Zenith’s optional feature the powerful side-view camera solution quickly identifies, measures, and analyzes potential defects on hidden or obscured components.

Self-Diagnosis

Optimal Performance Maintenance:The leading-edge Zenith 2 AOI incorporates a patented mechatronic technology, which positions it as the ultimate AOI solution. Self-Diagnosis allows operators to take precautionary measures through predictive maintenance in order to reduce process interruptions, enhance equipment uptime, and ensure optimal machine performance.

The Self-Diagnosis feature comes with distinct modules which offers periodical machine checkups on criticalitems such as 3D/2D light intensity, PZT feed, height accuracy, and XY offset.

AI-powered Auto Programming (KAP)

AI Power:Industry-leading 3D profilometry technology converges with Koh Young’s proprietary AI technology to deliver true automatic programming. The innovative geometry-based Koh Young Auto Programming (KAP) software solution reduces the programming process to minimizes time to production and reduces costs.

KOH YOUNG Zenith 2 3D AOI SMT AOI Picture Show:

EXHIBITION:

SMT LINE: