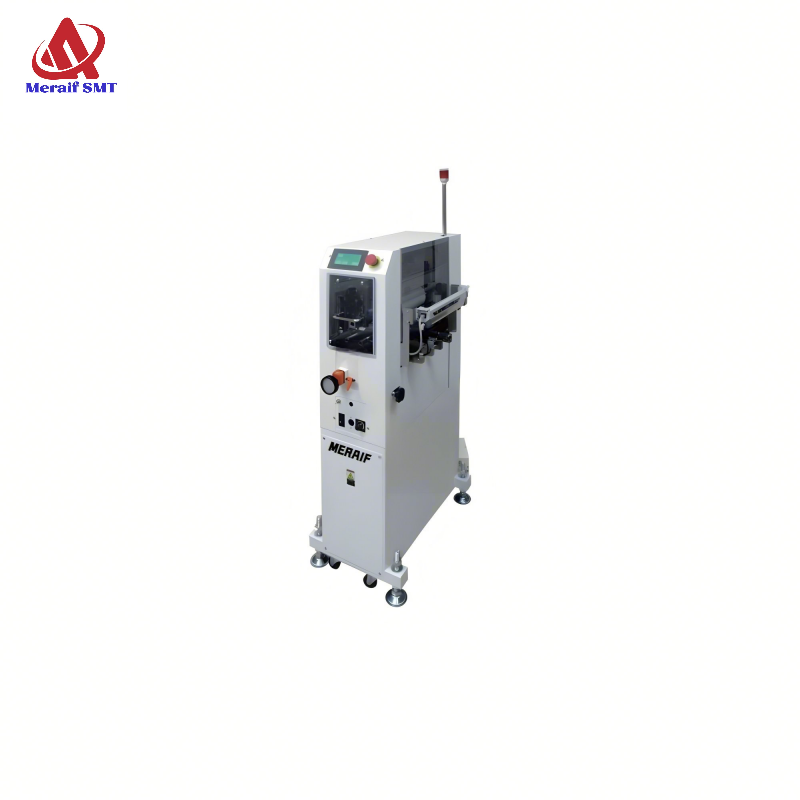

MERAIF MF-250 PCBA Clean Machine PCB Cleaning Machine PCB Board Cleaning Machine PCB Cleaner Machine For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

MERAIF MF-250 PCBA Cleaning Machine Technical Parameters :

|

Model: |

MF-250 |

|

Overall dimensions (L×W×H): |

Approx. 555x725x1650mm |

|

PCB size(L×W): |

50*50 ~ 330*250(MM) (Other sizes can be based on customer requirements) |

|

PCB board thickness: |

0.5-3.0mm |

|

Transmission direction: |

fixed in front of the track; left to right (right to left optional) |

|

Transmission height: |

900±25(MM) |

|

Power supply: |

AC220V/50-60HZ |

|

Transmission motor: |

Zhongda speed regulating motor |

|

Control system: |

Panasonic PLC control, Japan Panasonic SENSOR control system |

|

Control panel: |

Weintong touch screen operation panel |

|

Dust roller: |

customized |

|

Ball screw: |

TBI |

|

Anti-static Dust Adhesive Wheel Quantity: |

2 pcs |

|

Anti-static dust-sticking paper roll quantity: |

1 pcs |

|

Static elimination device: |

working voltage 7.0KV, import and export ion air rod (or optional by customer) |

|

Cylinder: |

Star |

|

Static electricity value: |

≤100V |

|

Frame material: |

3.0 iron plate welded, white electrostatic spraying |

|

Standard signal: |

using SMEMA standard 4-core signal line |

|

Note: Optional static electricity real-time monitoring system. Other requirements can be customized according to customer processes. |

|

MERAIF MF-250 PCBA Cleaning Machine Details:

The fully automatic PCB cleaning machine MF-250 produced by our company is mainly designed for the (SMT) surface mounting production process. The whole machine is composed of a static elimination system and a roller dust removal system. The anti-static roller + dust paper combination is the most popular one in the market industry today. Recognized as the most efficient cleaning method.

This machine is suitable for online cleaning of fine particles and other foreign matter on the surface of PCB boards after laser marking and before solder paste printing or adhesive coating. The dust roller is a self-adhesive dust removal product that can quickly remove various electronic products during the production process. The tiny particles, impurities, fibers, copper shavings, dust, etc. generated in the dust collector can be easily transferred to the sticky paper roll for collection. The static elimination system effectively eliminates the static electricity remaining on the PCB, and effectively controls possible defects and damage caused by foreign matter in advance, thereby reducing product hazards, improving product quality, and allowing you to have the most advanced contact cleaning system.

1. Panasonic PLC control system, touch screen operation, simple and easy to understand.

2. Double imported dust roller, automatic lifting design.

3. The unique design of the brush device can effectively clean the larger dust and protect the wear of the dust roller.

4. 1 electrostatic eliminator in each inlet and outlet can efficiently remove static electricity from PCB.

5. Transmission by stepper motor drive, precise and stable.

6. The central support function should play a key role in the possible deformation of the big PCB.

7. Modular design of the whole machine, convenient and quick maintenance.

8. SMEMA interface.

Features:

Overall dimensions: Overall dimensions (L×W×H): approximately 555x725x1650mm

PCB size: (L×W)~(L×W)50*50 ~ 330*250(MM) (Other sizes can be based on customer requirements)

PCB board thickness: 0.5-3.0mm

Transmission direction: fixed in front of the track; left to right (right to left optional)

Transmission height: 900±25(MM)

Power supply: AC220V/50-60HZ

Transmission motor: Zhongda speed regulating motor.

Control system: Panasonic PLC control, Japan Panasonic SENSOR control system

Control panel: Weintong touch screen operation panel

Dust roller: customized

Ball screw:TBI

Anti-static Dust Adhesive Wheel Quantity: 2 pcs

Anti-static dust-sticking paper roll quantity: 1 pcs

Static elimination device: working voltage 7.0KV, import and export ion air rod (or optional by customer)

Cylinder: Star

Static electricity value: ≤100V

Frame material: 3.0 iron plate welded, white electrostatic spraying

Standard signal: using SMEMA standard 4-core signal line

Note: Optional static electricity real-time monitoring system.

Other requirements can be customized according to customer processes.

EXHIBITION:

SMT LINE: