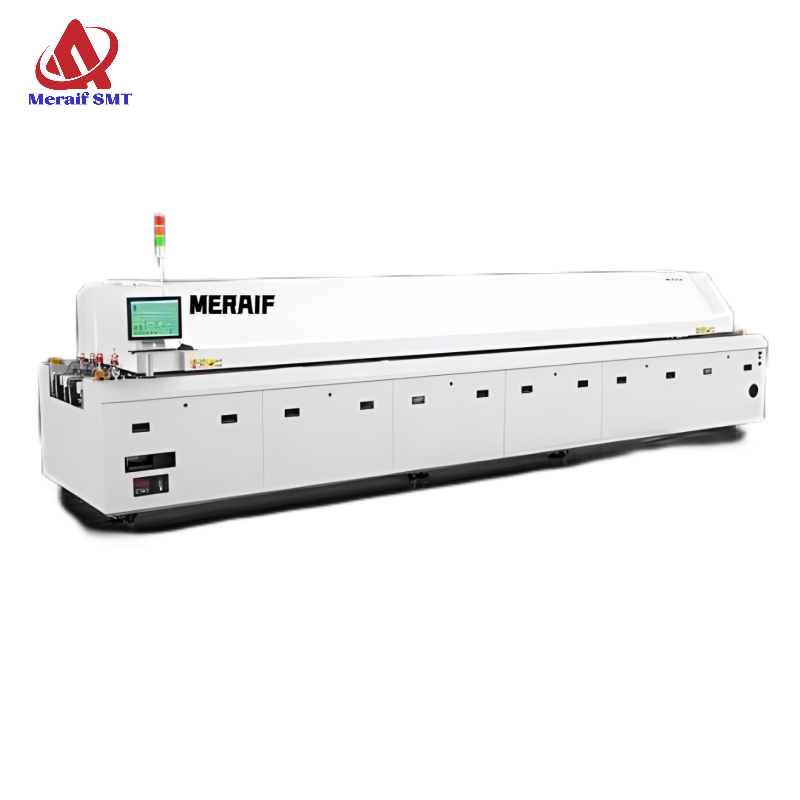

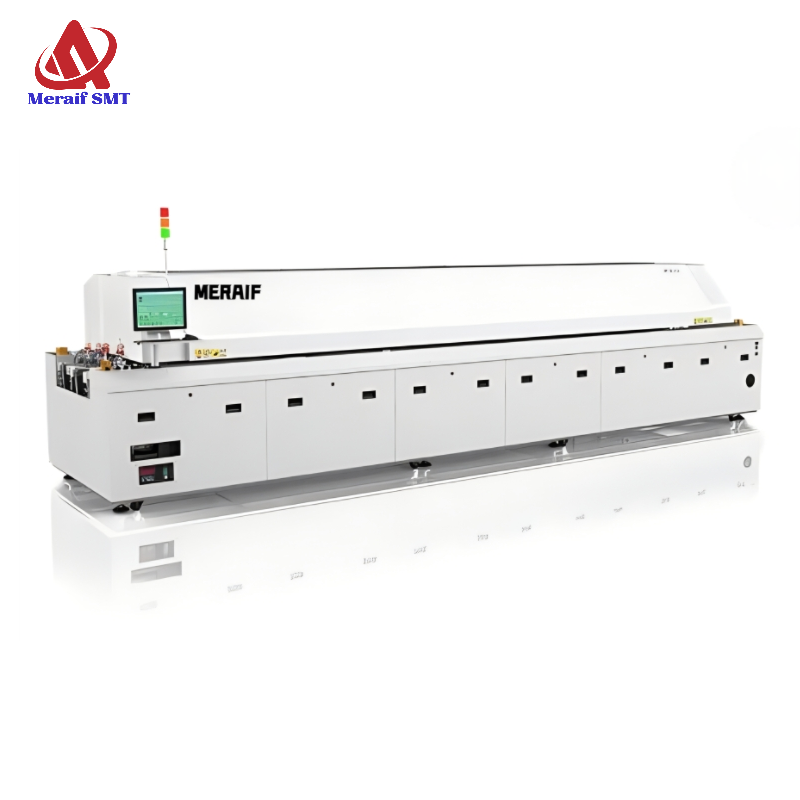

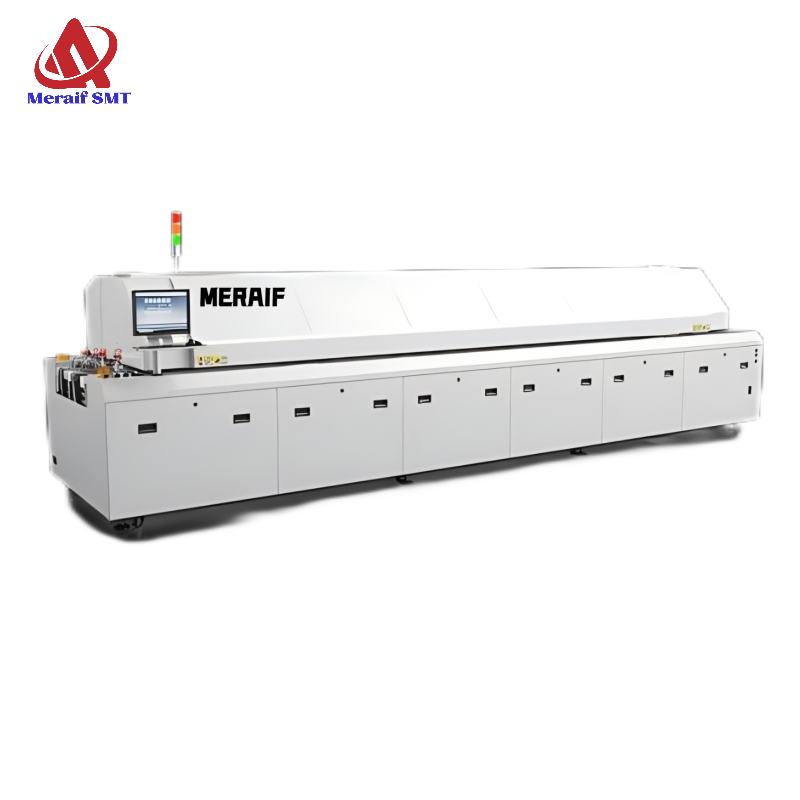

MERAIF MF-RO708 SMT Reflow Oven Reflow Oven PCB Reflow Oven Reflow Soldering Oven Reflow Solder Oven Solder Reflow Oven For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

MERAIF MF-RO708 Solder Reflow Oven SMT Reflow Oven Technical Parameters:

|

Model |

SMT-800N |

SMT-1000N |

SMT-1200N |

|

Number of heating zones |

Up 8/Down 8 |

Up 10/Down 10 |

Up 12/Down 12 |

|

Length of heating zone |

3110mm |

3892m |

4640mm |

|

Number of cooling zones |

Upper 2 (cold air internal circulation) |

Upper 3 (cold air internal circulation) |

|

|

Exhaust volume requirement |

10m³/minx2 |

||

|

Power requirement |

3-phase, 380V 50/60Hz |

||

|

Total power |

64KW |

80KW |

92KW |

|

Start-up power |

30KW |

36KW |

40KW |

|

Normal power consumption |

9KW |

10KW |

11KW |

|

Heating time |

Approx:25min |

||

|

Temperature control method |

PID closed-loop control + SRS drive (computer + PLC control) |

||

|

Temperature control accuracy |

±1 degree |

||

|

Maximum PCB width |

400mm |

||

|

Component height |

30mm on PCB board/25mm below |

||

|

Transport direction |

L-R or R-L |

||

|

PCB transport method |

Guide rail + mesh belt transport |

||

|

Conveyor belt height |

900±20mm |

||

|

Transport speed |

300-2000mm/min |

||

|

Cooling method |

Forced air cooling (optional chiller cooling) |

||

|

Dimensions |

5220x1430x1530mm |

6000xl430x1530mm |

7050x1430x1530mm |

|

Weight |

Approx.2400kg/2500kg |

Approx.2700kg/2800kg Approx.3000kg/3100kg |

|

|

Nitrogen consumption |

300-1000PPMat 20M³/hr(standard)/500-1000PPM at 25-30M/hr³(“-D”or "-L"models) |

||

MERAIF MF-RO708 Solder Reflow Oven SMT Reflow Oven Details:

1. The furnace uses a fully protected closed design to effectively prevent nitrogen loss, so that the oxygen content can be as low as 500PPM;

2. Low nitrogen consumption, only 18-25m³/H in an oxygen concentration environment of 500-1000ppm;

3. The new cooling structure design allows most of the exhaust gas to be filtered or recycled back into the furnace, reducing heat loss and making the flux recovery more thorough.

4. 15% improvement in heat transfer efficiency, calmly responding to more complex and larger welding quality process requirements.

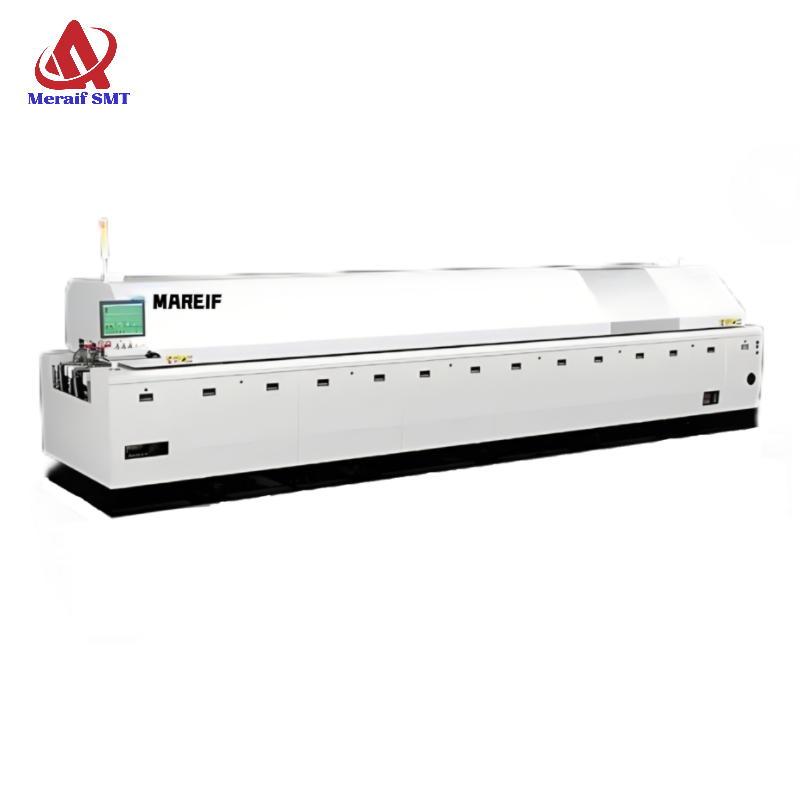

MERAIF MF-RO708 Solder Reflow Oven SMT Reflow Oven Picture Show:

EXHIBITION:

SMT LINE: