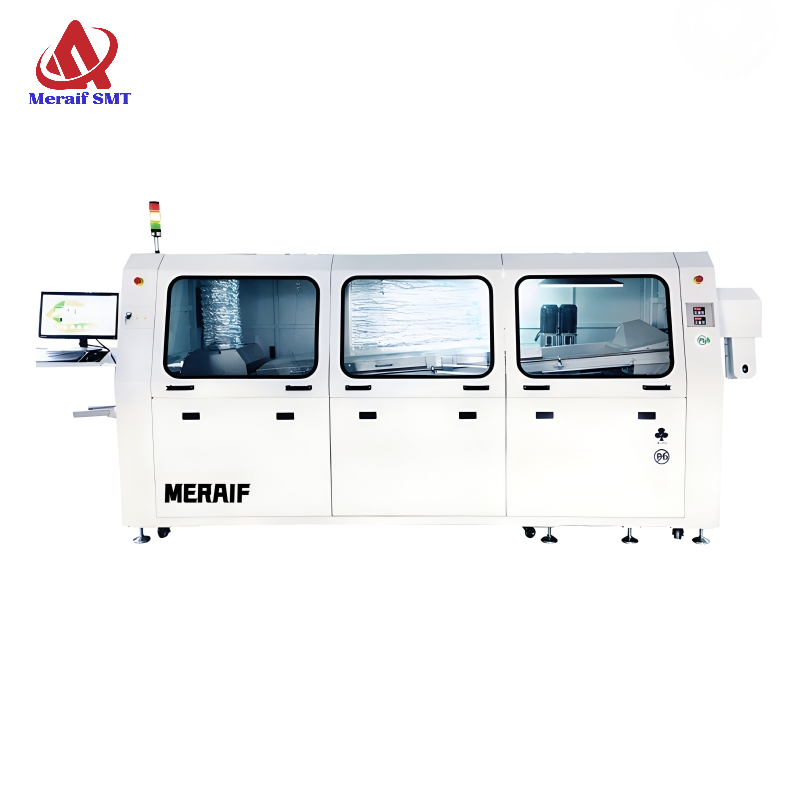

MERAIF MF-S300 Wave Soldering Machine Automatic SMT wave Soldering Machine For SMT Machine Line SMT Assembly Line DIP Insertion Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

MERAIF MF-S300 Wave Soldering Machine Technical Parameters:

Model

MF-S300

PCB conveying direction

Standard L→R

Dimensions

L3150mmxW1200mmxH1570mm

Conveying speed range

500mm~1800mm

Weight

Approx. 650kg

Transport height

750mm±20mm

Power

3PH 380V 50HZ

Allowable PCB original height

105mm up and 10mm down

Start-up power

11KW

Speed control method

Inverter closed loop stepless speed regulation

Normal operating power

Approw 3kw

Guide rail angle

4~7

Control system

Touch screen + PLC

Tin furnace type

Mechanical

Spray movement

Stepper motor movement

Tin furnace material

5mm 316L stainless steel

Spray air pressure

0.2Mpa-0.4Mpa

Crest adjustment method

Inverter

Exhaust mode

Upward exhaust

Crest height

Disturbance wave ≤10mm width flat wave ≤10mm

Exhaust pipe diameter

150

Cooling method

Downward air flow

Exhaust volume

15m³/min

Tin furnace heating power

220V 6KW

Preheating mode

Micro hot air

Tin furnace maximum temperature

300℃

Preheating control mode

PID

Tin furnace capacity

280kg (solder liquid level too low alarm)

Number of preheating zones

2

Crest drive power

180Wx2220VAC

Length of preheating zone

950mm

Tin furnace heating time

Approx.120min(setting:250℃)

Adjustable preheating temperature range

Room temperature ~150℃

Furnace temperature control method

PID

Preheating heating time

Approx.12min (setting:100℃)

Hot air motor

45W 220VAC

Width range

Light double claw 50mm-270mm

Claw

Lightweight double claw

MERAIF MF-S300 Wave Soldering Machine Details:

1. The furnace uses a fully protected closed design to effectively prevent nitrogen loss, so that the oxygen content can be as low as 500PPM;

2. Low nitrogen consumption, only 18-25m³/H in an oxygen concentration environment of 500-1000ppm;

3. The new cooling structure design allows most of the exhaust gas to be filtered or recycled back into the furnace, reducing heat loss and making the flux recovery more thorough.

4. 15% improvement in heat transfer efficiency, calmly responding to more complex and larger welding quality process requirements.

MERAIF MF-S300 Wave Soldering Machine Picture Show:

EXHIBITION:

SMT LINE: