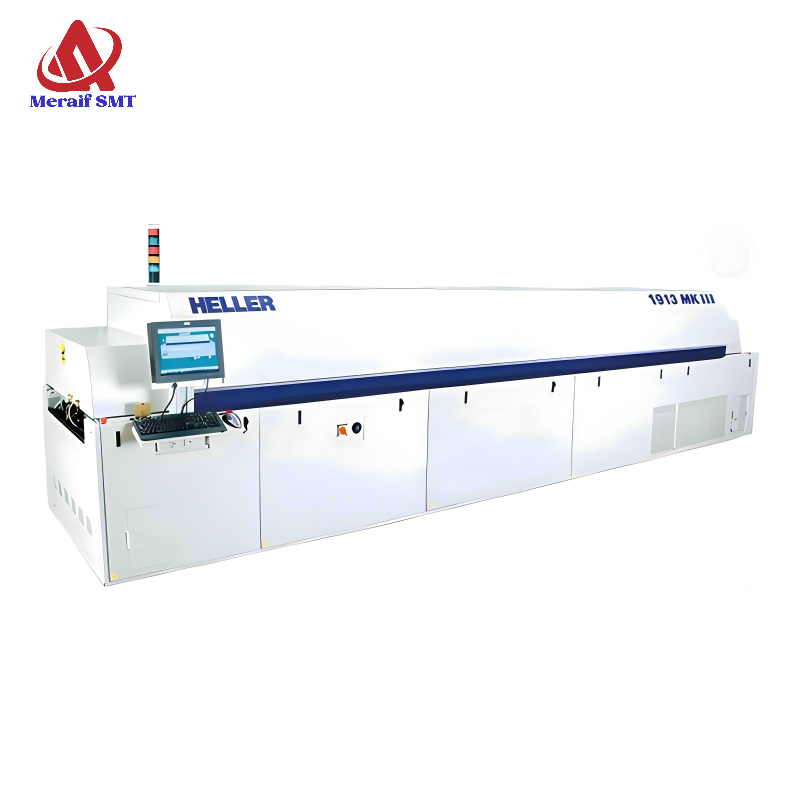

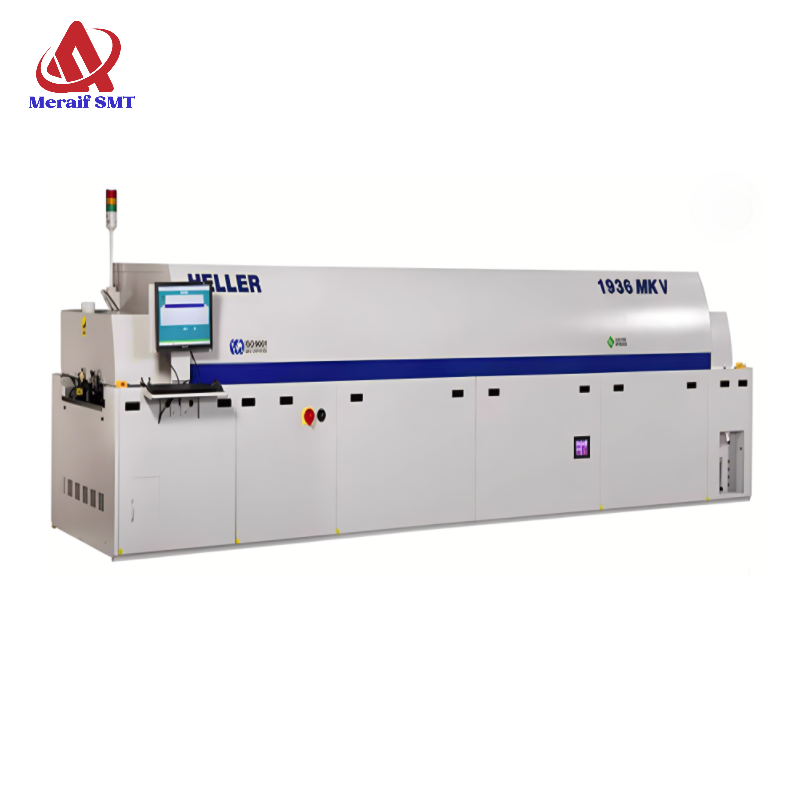

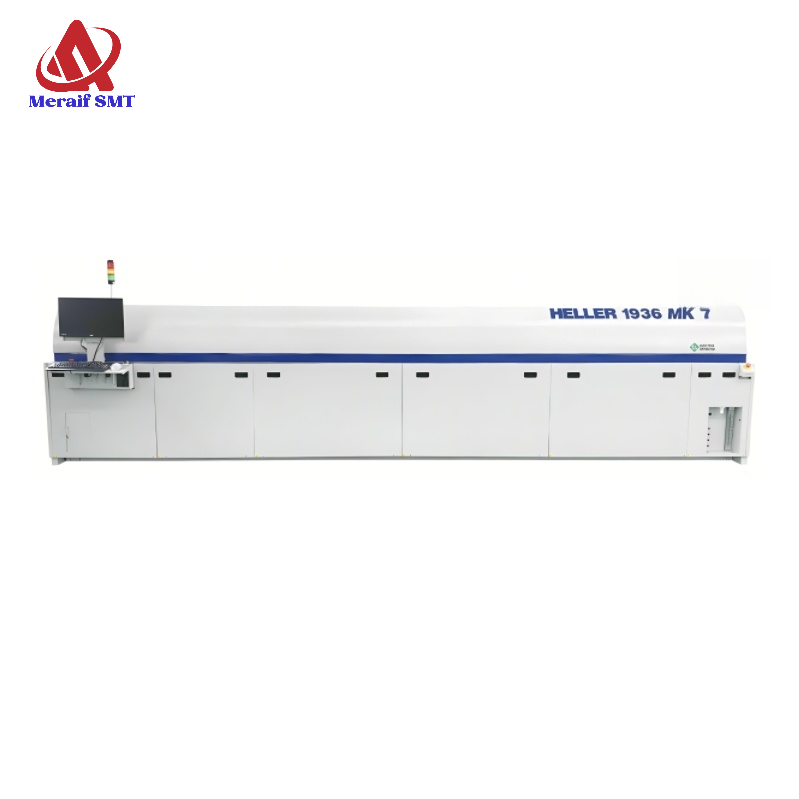

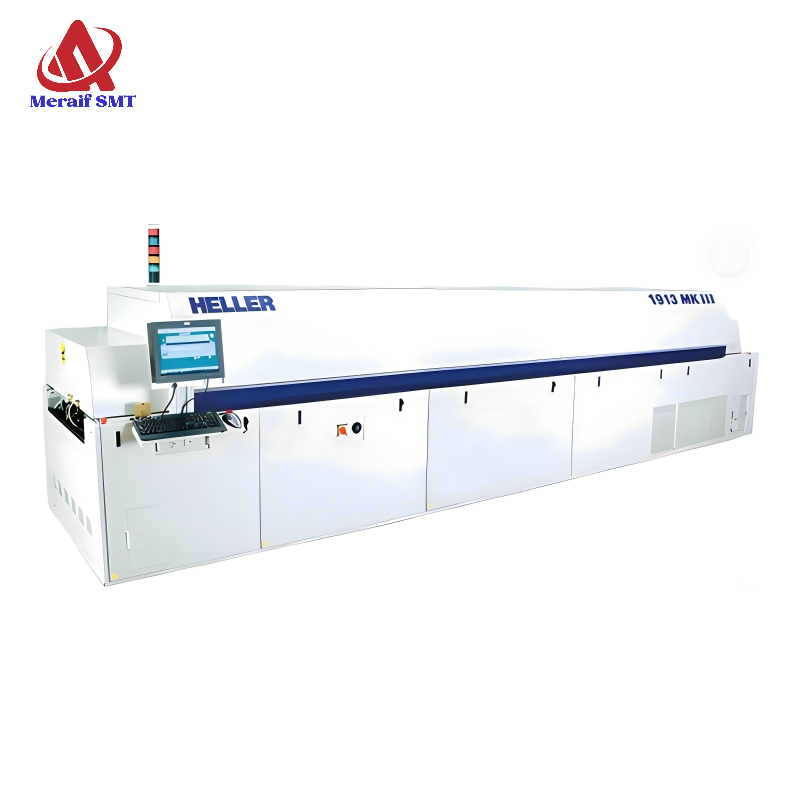

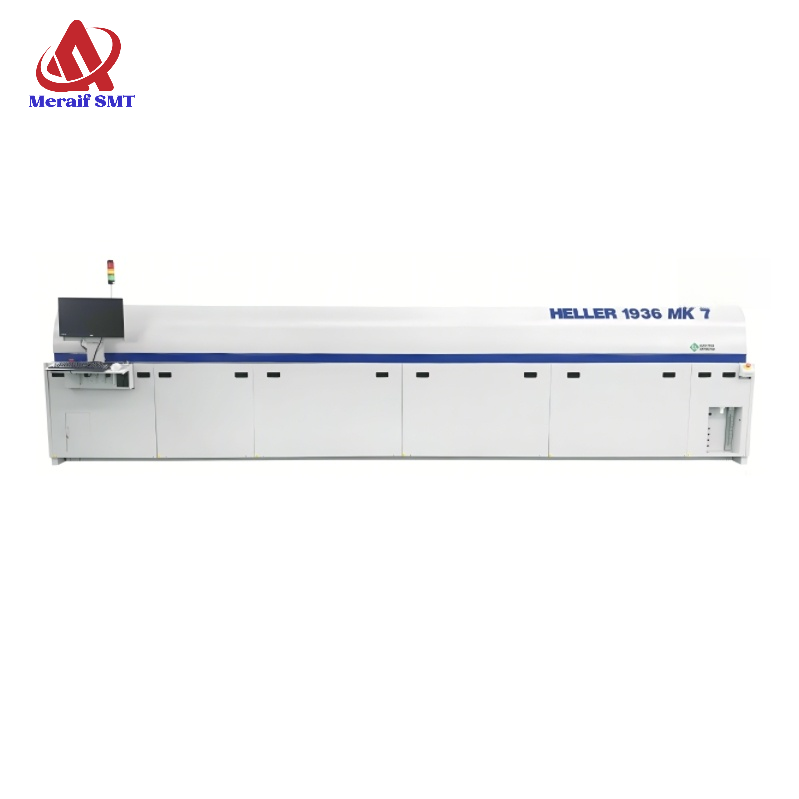

HELLER 1809 MK III SMT Reflow Oven Reflow Oven PCB Reflow Oven Reflow Soldering Oven Reflow Solder Oven Solder Reflow Oven For SMT Machine Line SMT Assembly Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

HELLER 1809 MK III Solder Reflow Oven Technical Parameters :

|

MODEL |

1809MKIII (Air) |

1809MKIII (Nitrogen) |

|

Electric Supply |

||

|

Power Input (3 Phase)Standard |

480 volts |

480 volts |

|

Breaker Size |

100 amps @480v |

100 amps @480v |

|

kW |

7.5-16 Continuous |

7.5-16 Continuous |

|

Typical Run Current |

30-35 amps @480v |

30-35 amps @480v |

|

Optional Power Inputs Available |

208/240/380/400/415 VAC |

208/240/380/400/415 VAC |

|

Frequency |

50/60 Hz |

50/60 Hz |

|

Sequential Zone Turn On |

S |

S |

|

Dimensions |

||

|

Overall Oven Dimensions |

183"(465cm)Lx56"(142cm)Wx63”(160cm)H |

183"(465cm)Lx56"(142cm)Wx63”(160cm)H |

|

Typical Net Weight |

43501bs. (1970 kg) |

4550 lbs. (2060 kg) |

|

Typical Shipping Weight |

5500 lbs. (2490 kg) |

5850 lbs. (2650 kg) |

|

Typical Shipping Dimension |

195”x73”x81” |

495x185x205 cm |

|

Computer Control |

||

|

AMD or Intel Based Computer |

S |

S |

|

Flat Screen Monitor w/Mount |

S |

S |

|

Windows Operating System |

Windows 8R Home Premium |

Windows 8B Home Premium |

|

Auto Start Software |

S |

S |

|

Data Logging |

S |

S |

|

Password Protection |

S |

S |

|

LAN Networking |

0 |

0 |

|

Inert Atmosphere |

||

|

Minimum PPMOxygen |

– |

10-25 PPM* |

|

Waterless Cooling w/Flux

Separation System

|

– |

0 |

|

Nitrogen On/OffValve |

– |

0 |

|

Oxygen Monitoring System |

– |

0 |

|

Nitrogen Standby System |

– |

0 |

|

Typical Nitrogen Consumption |

– |

500-700 SCFH** |

|

Additional Features |

||

|

KIC Profiling Software |

S |

S |

|

Signal Light Tower |

S |

S |

|

Powered Hood Lift |

S |

S |

|

Five (5)Thermocouple Profiling |

S |

S |

|

Redundant Alarm Sensors |

0 |

0 |

|

Intelligent Exhaust System |

0 |

0 |

|

KIC Profiler/ECD Profiler |

0 |

0 |

|

Center Board Support |

0 |

0 |

|

Board Drop Sensor |

0 |

0 |

|

Board Counter |

0 |

0 |

|

Bar Code Reader |

0 |

0 |

|

Custom Paint &Decal |

0 |

0 |

|

Battery Backup for Conveyor and PC |

0 |

0 |

|

GEM/SECS Interfacing |

0 |

0 |

|

Mesh Belt Conveyor |

||

|

Height From Floor |

35.5"±2.0"(90 cm±5 cm) |

35.5"±2.0"(90 cm±5 cm) |

|

Maximum PCB Width

**Requires wider heat module

|

18“(46 cm)**/22”(56cm)** |

18“(46 cm)22”(56 cm)** |

|

Space Required Between PCB's |

0.0"(0.0 cm) |

0.0"(0.0 cm) |

|

Conveyor Length On-Load |

18"(46 cm)* |

3"(7.5 cm)* |

|

Conveyor Length Off-Load |

18"(46 cm)* |

3"(7.5 cm)* |

|

Heated Tunnel Length |

105"(254 cm) |

105"(254 cm) |

|

Process Clearance Above Mesh Belt |

2.3"(5.8 cm) |

2.3"(5.8 cm) |

|

Mesh Belt Pitch |

0.5"(1.27 cm) |

0.5"(1.27 cm) |

|

Maximum Conveyor Speed |

74"/Min(188 cm/min.) |

74"/Min(188 cm/min.) |

|

Conveyor Direction Left to Right |

S |

S |

|

Conveyor Direction Right to Left |

0 |

0 |

|

Conveyor Speed Control |

Closed Loop |

Closed Loop |

|

Edge Hold Conveyor System Option |

||

|

Height from Floor-Standard |

37.0"±2.0"(94 cm±5 cm) |

37.0"±2.0"(94 cm±5 cm) |

|

Height from Floor-Optional |

32.6"+3.9"/-.4"

(83 cm+10 cm/-1 cm)

|

32.6"+3.9"/-.4"

(83 cm+10 cm/-1 cm)

|

|

Clearance Above & Below Conveyor Pins |

1.15"(2.9 cm) |

1.15"(2.9 cm) |

|

Length of PCB Support Pins |

.187"(4.75 mm) |

.187"(4.75 mm) |

|

3 mm long support pins |

0 |

0 |

|

Minimum/Maximum Board Width |

2.0"-18"(5-46 cm)

22”(56cm)optional

|

2.0"-18"(5-46 cm)

22”(56cm)optional

|

|

Power Width Adjustment |

S |

S |

|

Computer Controlled Width Adjust |

0 |

0 |

|

Auto Lubrication System |

0 |

0 |

|

Forced Convection Zones |

||

|

Top &Bottom |

9 |

9 |

|

Heater Type |

Instant response open coil |

Instant response open coil |

|

Heater Material |

Nichrome |

Nichrome |

|

Profile Change Time |

5-15 minutes |

5-15 minutes |

|

Temperature Control |

||

|

Accuracy of Temperature Controller |

+.1C |

+.1°C |

|

Cross-Belt Temperature Tolerance |

+2.0℃ |

±2.0℃ |

|

Heater Wattage Per Zone |

6000w** |

6000 w** |

|

Temperature Range Standard |

60-350℃ |

60-350℃ |

|

High Temperature Up to 450℃ |

0 |

0 |

|

Cooling Systems |

||

|

Number of Cooling Zones Standard |

2 |

2 |

|

Additional Cooling Zones |

0 |

0 |

|

Water Cooling |

|

0 |

|

Notes:S=Standard,O=Optional. *A 12"(30 cm)Conveyor extension is an available option **380V heater wattage 4800 |

||