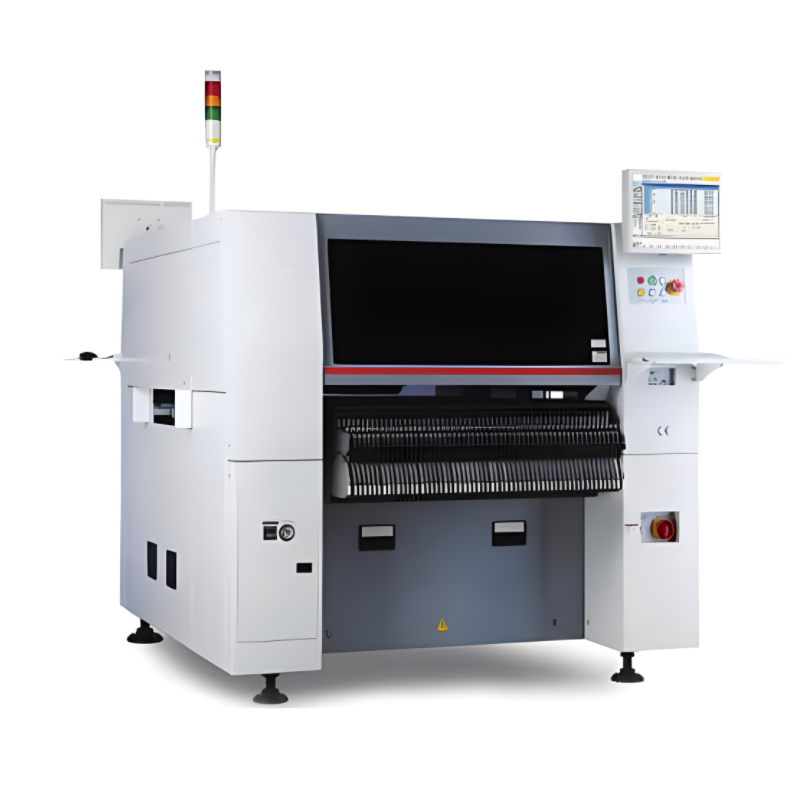

SMT Placement Solution Smd Mounting Machine Hanwha HM520HS Pick and Place Machine Led Pick and Place Machine For SMT Assembly Line SMT Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

Hanwha HM520HS Pick and Place Machine Technical Parameters :

Hanwha HM520HS Pick and Place Machine Details:

Model

HM520 HS

Number of Heads

Double Gantry 20 Heads (40 total)

Placement Speed

80,000 CPH (Vision Optimum)

Vision

Vision Stage Camera

Placement Accuracy

Chip: ±25µm Cpk ≥ 1.0

Components

Dimensione

0201 - 6 mm

Max Altezza

2mm

PCB Dimension (mm)

Single

Double

Feeder Capacity (8mm standard)

80ea (8mm Docking Cart)

Utility

Power

Air Consumption

100NI/min

Weight

1,605kg

External Dimension (LxDxH mm)

890x2,312x1,921

Ideal mounter for high volume/high performance electronics, such as mobile phones and automotive applications.

With component sizes shrinking and PCBs becoming more densly populated, the placement repeatability and accuracy is more critical. The Hanwha HM520 series is ideally suited to this style application.

The HM520 HS Module can handle the smaller chip components at very high speed using the rotary heads to achive that. The FS module is a multi function module, capable of placing larger components up to 55mm square including shield can devices.

HM Series machines are fully traceable from component tracking, PCB tracking by barcode and fully Intelligent system. All managed and controlled by the T-Solution Factory management software.

Key Advantages of HM Series:

- Reduction in Line Length with High Throughput

- Very Low Cost of Ownership

- Easy to use Software

- Ideal for high-volume/High Mix production

- Improved Axis and frame design over previous chipshooter models giving greater speed and higher precision

- Improved component range and now capable of placing 0.2mm x 0.1mm components at high speed

- Easy to use MMI and Off Line Software with Touch Screen for operator convenience

- Fully Modular System depending on target cph needed and feeder requirement

- New Feeder Type for High Speed Indexing and intelligent as standard

Hanwha HM520HS Pick and Place Machine Picture Show:

EXHIBITION:

SMT LINE: