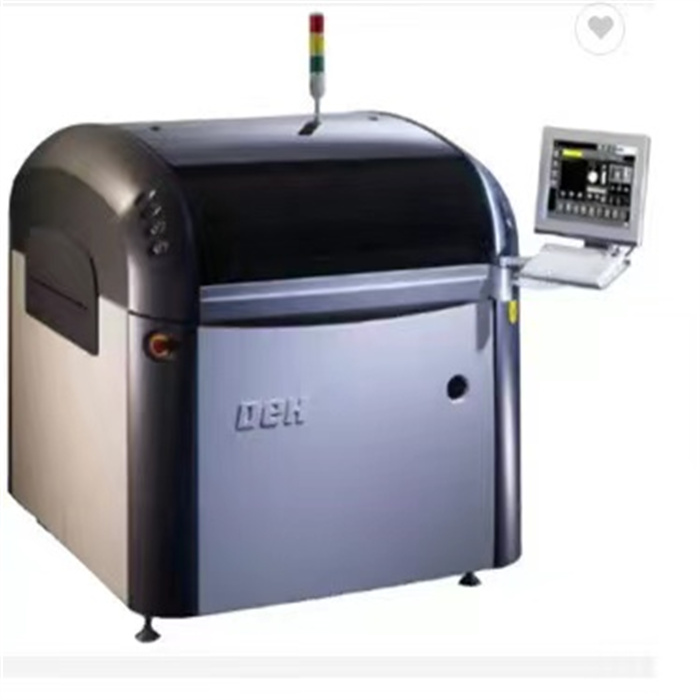

DEK Galaxy Fully Automatic SMT Screen Printer

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

DEK Galaxy Fully Automatic SMT Screen Printer Technical Parameters :

|

Machine Features |

DEK Galaxy |

|

Repeat accuracy |

± 12.5 μm @ 2.0 Cpk (± 6 sigma)# |

|

Printing accuracy |

± 12.5 μm @ 2.0 Cpk (±6 sigma)# |

|

Standard cycle time |

7 sec |

|

Maximum printing surface |

510 mm* (X) x 508.5 mm (Y) |

|

Maximum substrate size |

620 mm (X)* x 508,5 mm (Y)# |

|

Frame variants |

305 mm to 736 mm (12″** to 29″), max. frame thickness: 38 mm |

|

User interface |

Touchscreen, keyboard and trackball, DEK Instinctiv V9TM software |

|

Camera |

HawkEye® 1700 |

|

Squeegee adjustment |

Software controlled, motorised with closed loop feedback |

|

Stencil positioning |

Automatic loading incorporating squeegee drip tray |

|

Stencil alignment |

Motorised via actuators X, Y, and Theta |

|

Printing speed |

2 mm/sec to 300 mm/sec |

|

Fiducial recognition |

Automatic fiducial recognition, programmable from 0.1 mm to 3 mm |

|

Understencil Cleaning |

Cyclone high speed cleaner,fully programmable with wet/dry/vacuum wipe with external solvent tank |

|

Compressed air supply |

5-8 bar at 5 liters/minute |

|

Power supply |

110 V to 240 V ±10 %, 50/60 Hz |

|

Weight |

Approx. 680 kg |

|

# DEK’s machine accuracy and repeatability qualification is certified by 3rd party and undertaken using production environment |

|

Advanced semiconductor packaging and high precision SMT assembly convergence.

Galaxy unites advanced semiconductor packaging and high precision next-generation SMT assembly on the same platform. This level of convergence delivers the advanced technological capabilities that are essential for emerging packaging technologies and assembly challenges. Equipped to handle a range of high accuracy applications at wafer, substrate and board level, Galaxy is ideal for complex packages such as flip-chips, uBGAs and ultra fine pitch SMT.

Galaxy addresses the ever present need for resource maximisation, as it can be configured and easily re-deployed to host a number of different packaging processes including wafer bumping, ball placement, singulation, thermal interface material (TIM) deposition and backside wafer coating. The system is compatible with industry-standard handling formats such as FOUPS or Auer boards, plus wafer chucks and DEK's Virtual Panel Tooling (VPT).

Delivering unprecedented flexibility; Galaxy’s immense capability and broad compatibility, combined with fast changeover, create a process-agnostic platform capable of rapid reassignment as business demands dictate. DirEKt Ball Attach to wafers or substrates, at ball diameters down to 0.2mm; wafer bumping by solder paste printing; SMT pre-placement for next generation assemblies including "silicon dust" components: deploy - and re-deploy - at will.

Standalone, or as part of a turnkey process configured by DEK specialists, Galaxy is the ultimate performer.

Features:

DEK Galaxy Fully Automatic SMT Screen Printer Picture Show:

Exhibition:

SMT LINE: